One-way wrench having a catching device with two catches and a catch holder and having differential teeth

a technology of catching device and wrench, which is applied in the field of wrench catching device, can solve the problems of wrenches not working in driving operation environment, wrenches are also likely to get damaged, and wrenches are not easy to operate in a driving operation environment, so as to reduce the cost of processing the wrench body and manufacturing and maintaining the catching device. the effect of reducing the cost of catching device and simplifying the wrench body structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]A preferred embodiment of a one-way wrench structure of the present invention is illustrated with FIGS. 1 through 4 and described below.

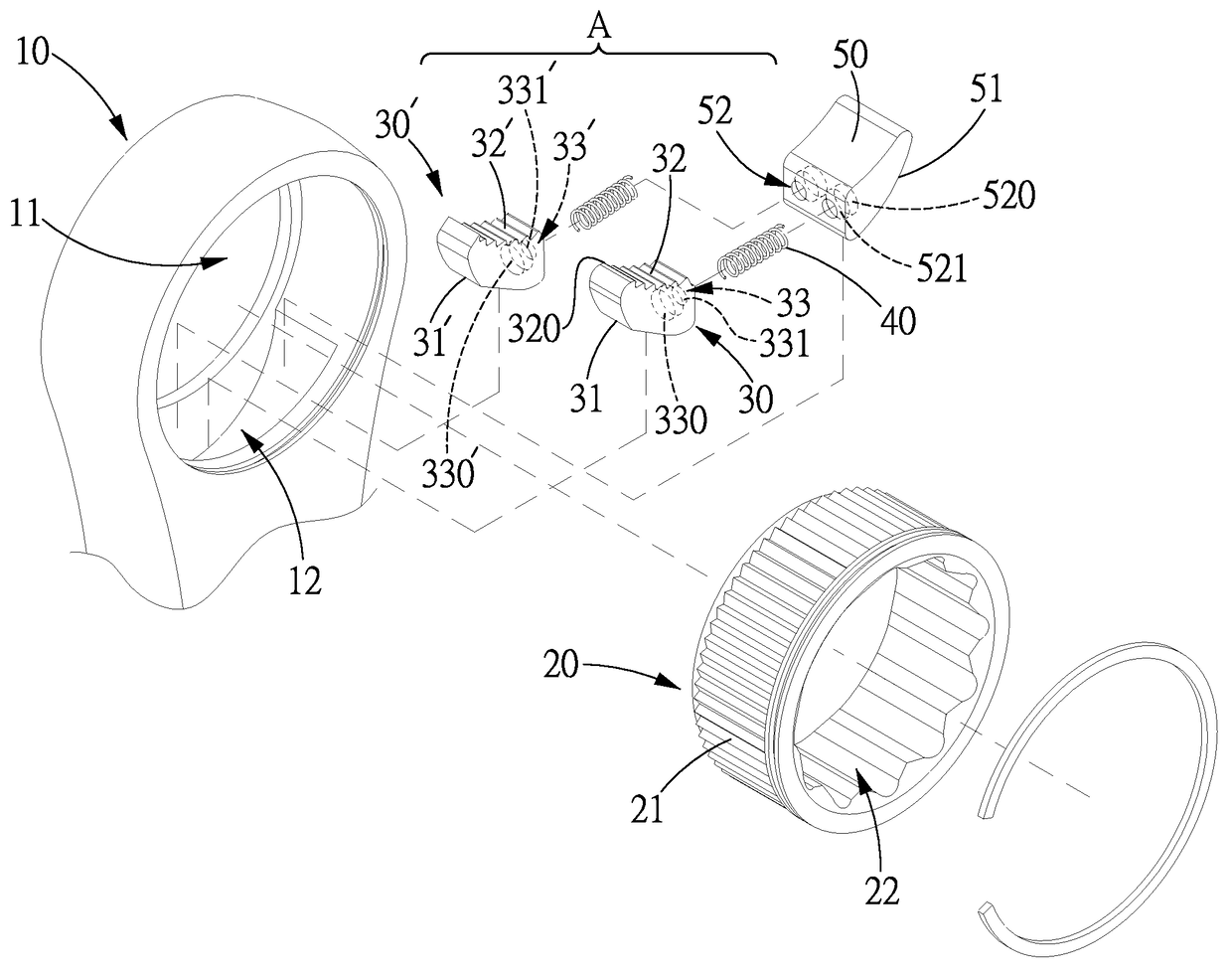

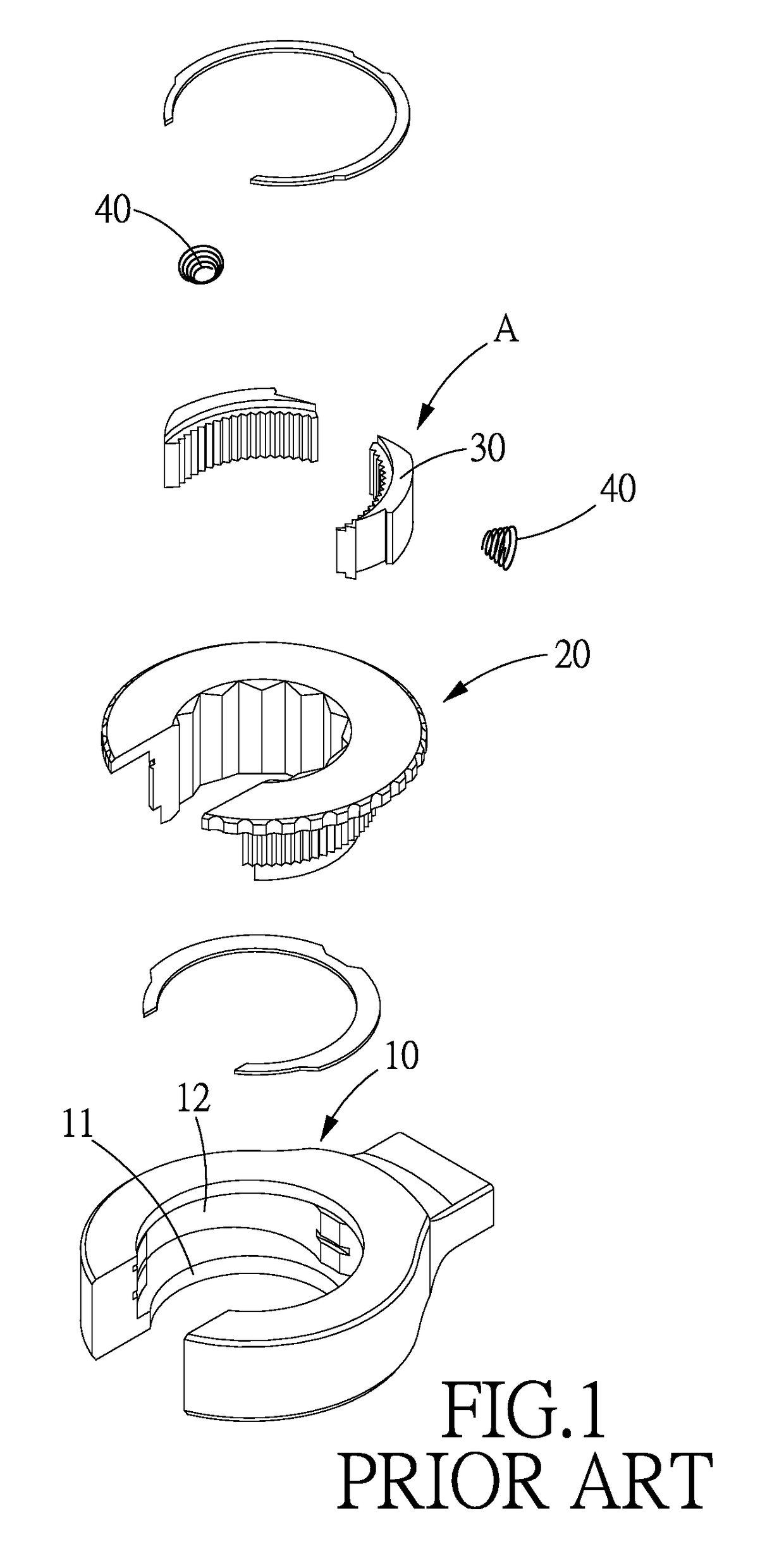

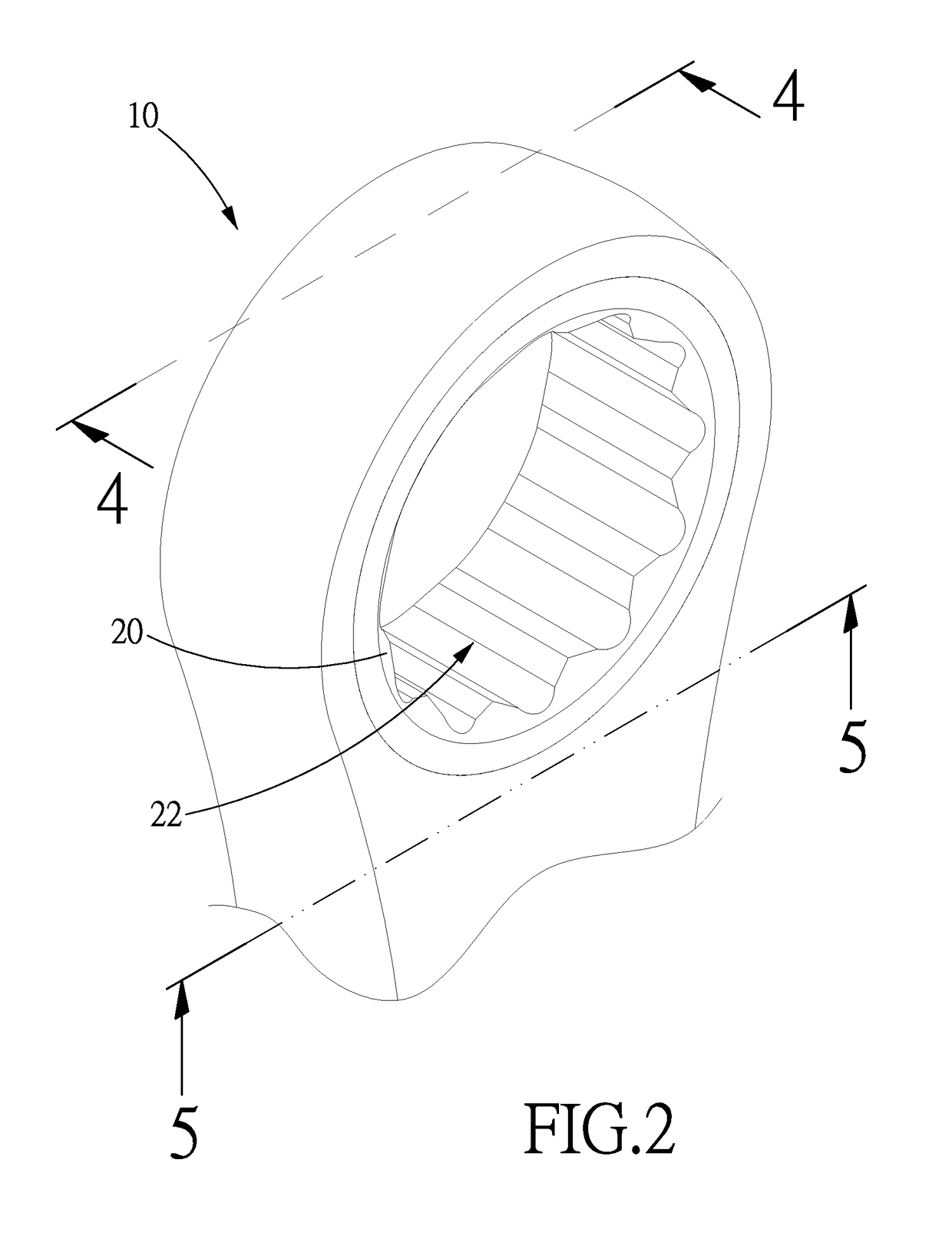

[0022]The wrench has a body 10, a driving element 20, and a catching device A disposed in the body 10. The catching device A has two catches 30, 30′, two position-restoring elements 40, and a catch holder 50. One end of the body 10 has a driving hole 11. A catching chamber 12 is laterally disposed beside the driving hole 11 and is in communication with the driving hole 11. The catching chamber 12 is shallow at its two ends and deep at its middle. The driving element 20 is externally provided with ratchet teeth 21 and internally provided with a penetrated driving hole 22 for driving a workpiece to rotate along with the wrench. The present invention has an essential technical feature, that is, one catching chamber 12 contains the catching device A which has two catches 30, 30′, two position-restoring elements 40, and one catch holder 50.

[0023]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com