Marked contact lens bearing optical marking element

a technology of optical marking and contact lens, which is applied in the field ofmarked contact lens, can solve the problems of inability to use inability to meet the needs of wet molded soft contact lens methods, and inability to achieve the effect of preventing the formation of dark marks on the lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

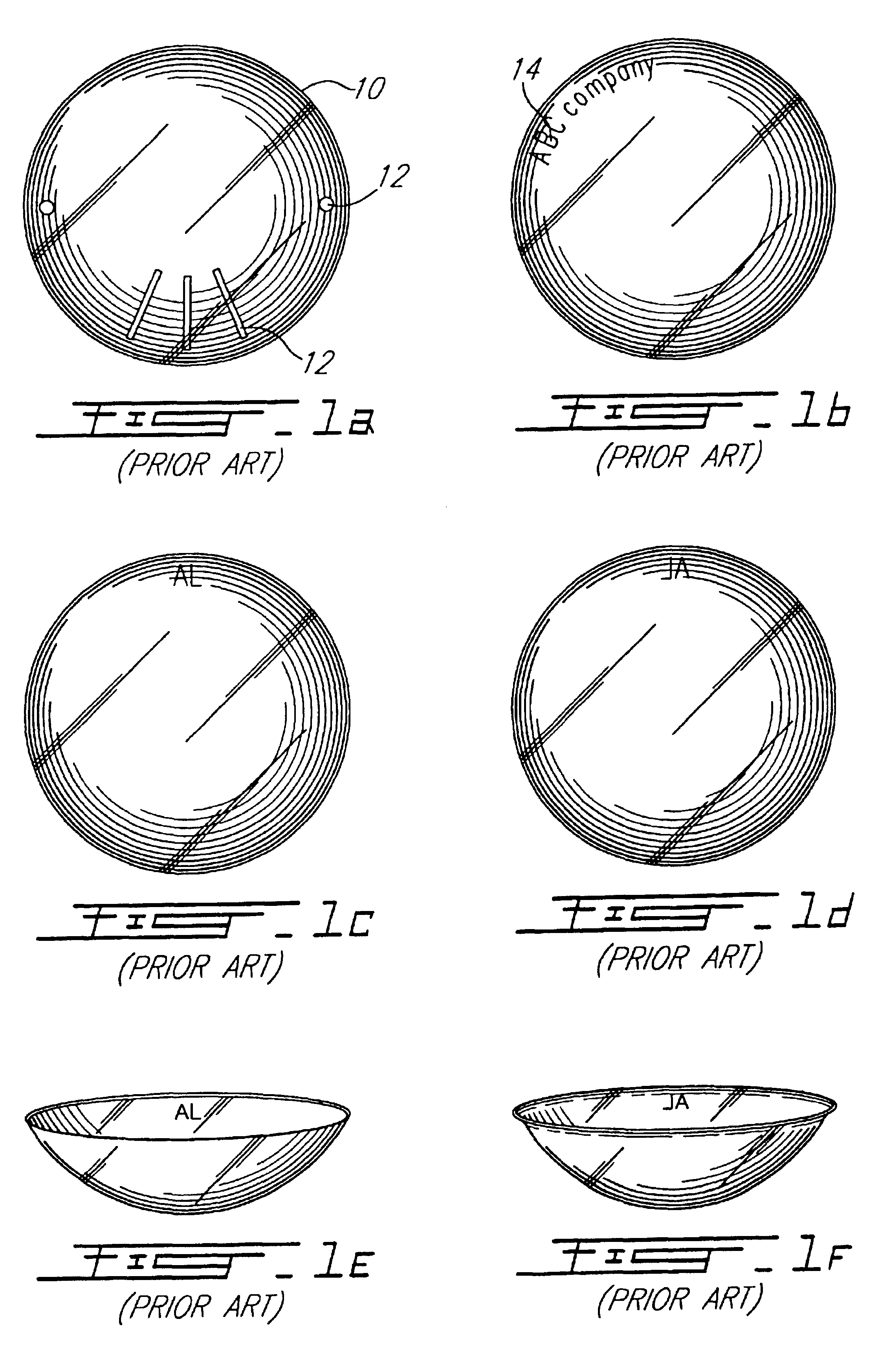

In the preferred embodiment, optical elements are used to mark lenses. These marks are used to provide lens position information to the lens user, so lenses may be worn in the right position. FIG. 1 shows printed and engraved marks used in the prior art in order to provide position information to the lens wearer.

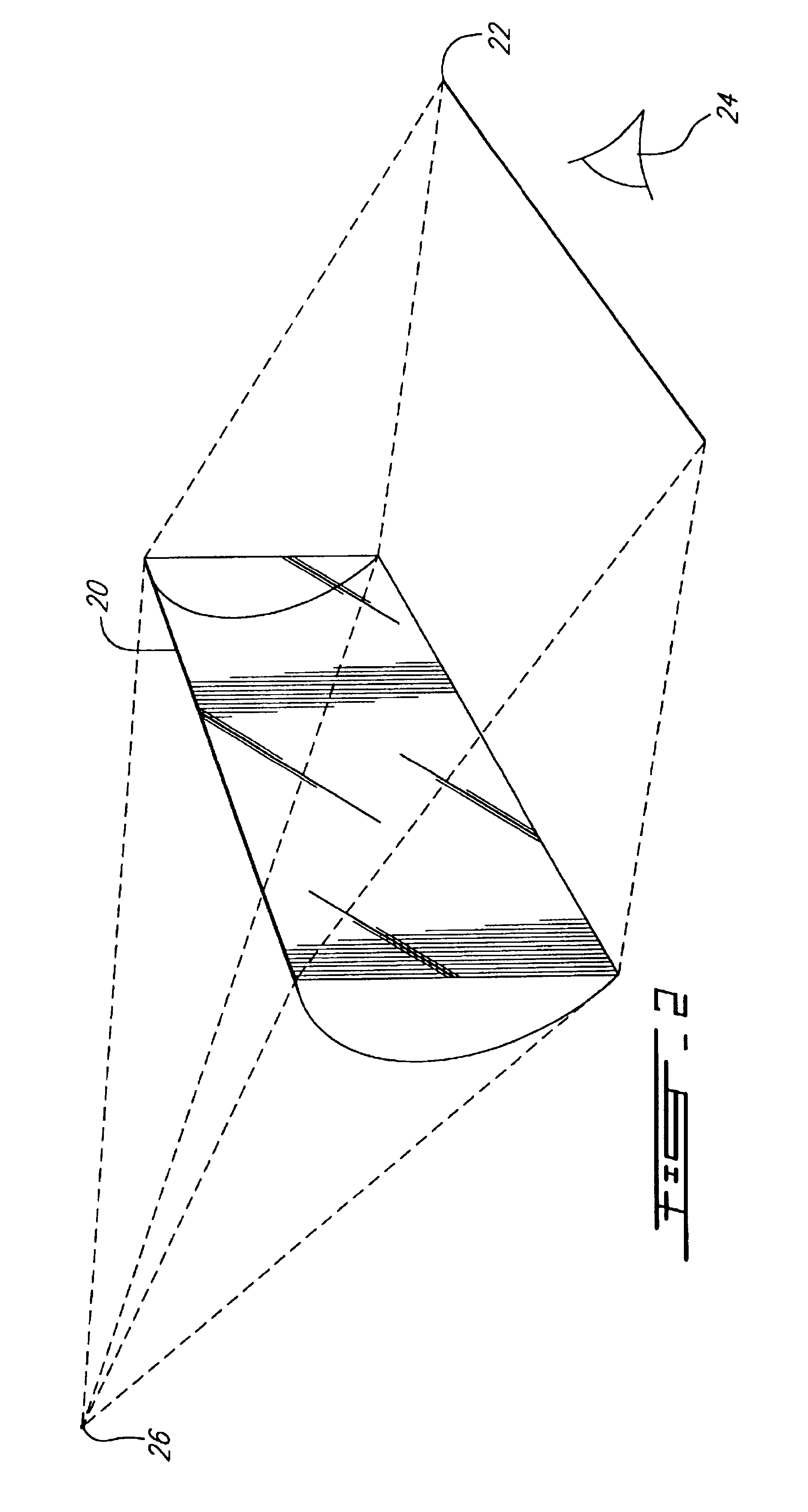

According to the present invention, semi-spherical or semi-cylindrical optical elements are provided on the surface of the contact lens for providing lens position information to the lens user. An important characteristic of such marks is that they are not felt or seen by the wearer while the lenses are worn. They are, however, clearly visible when the lens is examined visually, especially when held toward a light source. As an example, a semi-cylindrical optical element 20 is shown in FIG. 2; the cylindrical element 20 is seen as a straight line 22 when a user 24 looks through it at a light source 26.

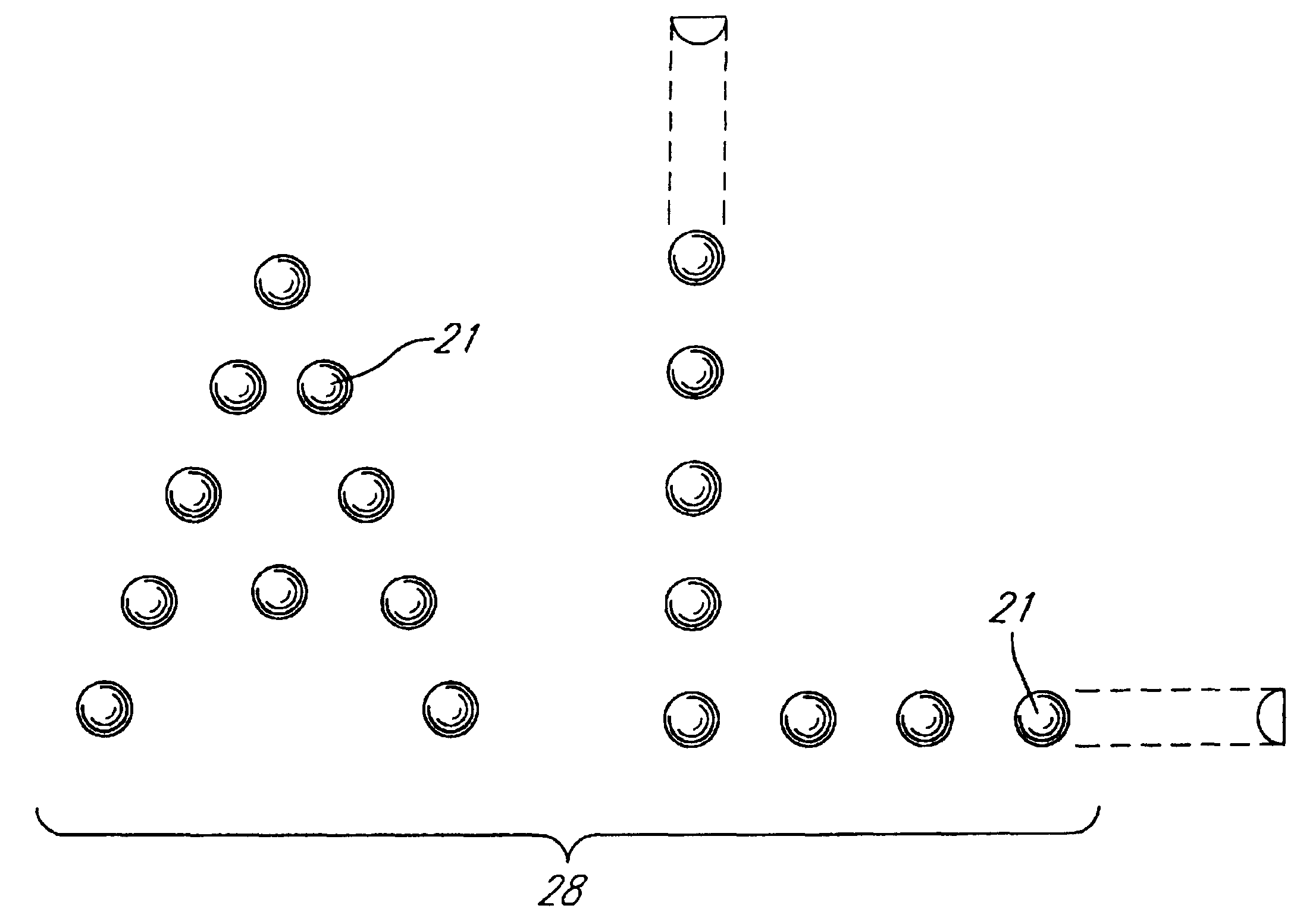

The optical marks on the contact lenses are composed by a plurality of mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com