Lead frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The First Preferred Embodiment

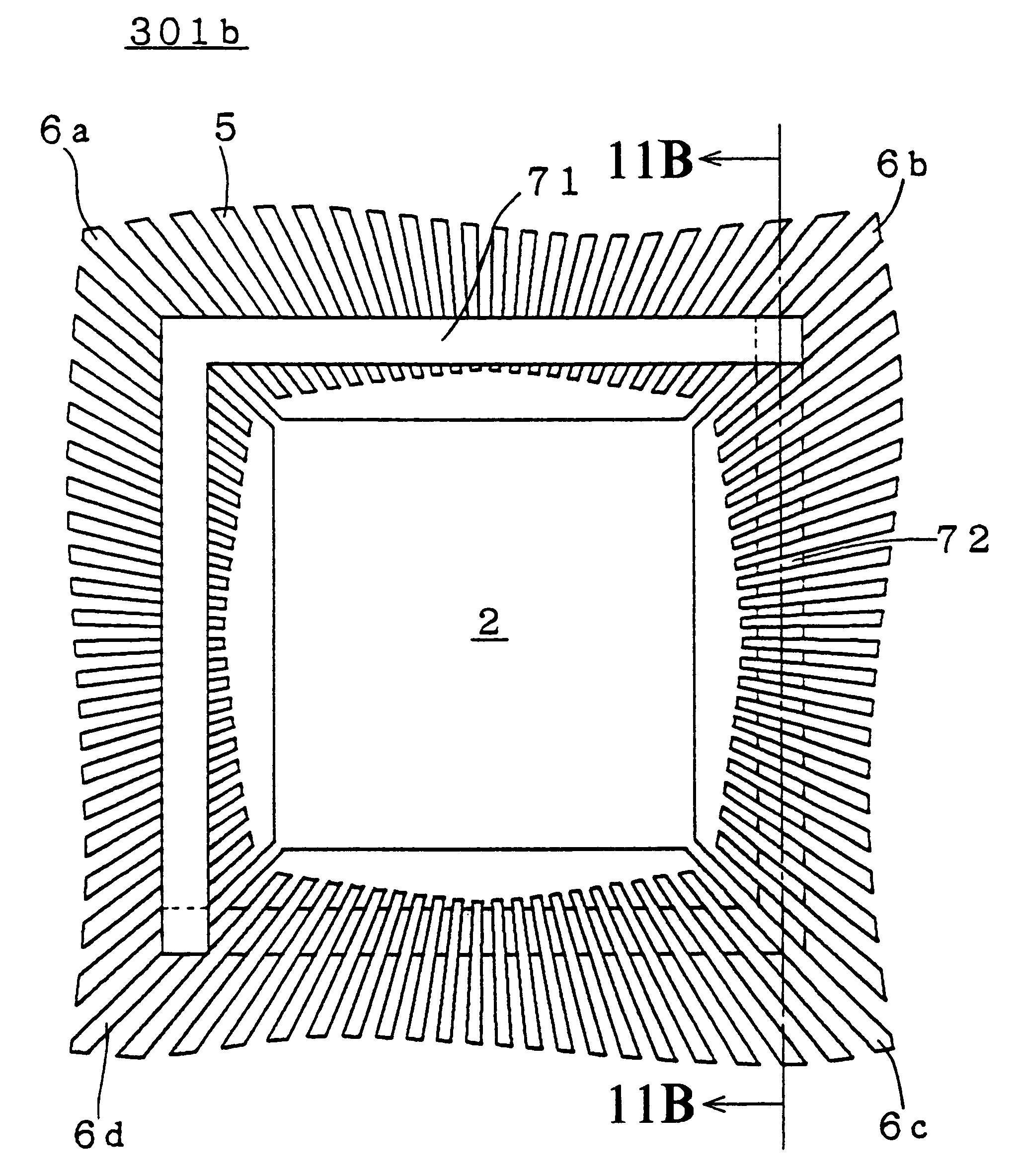

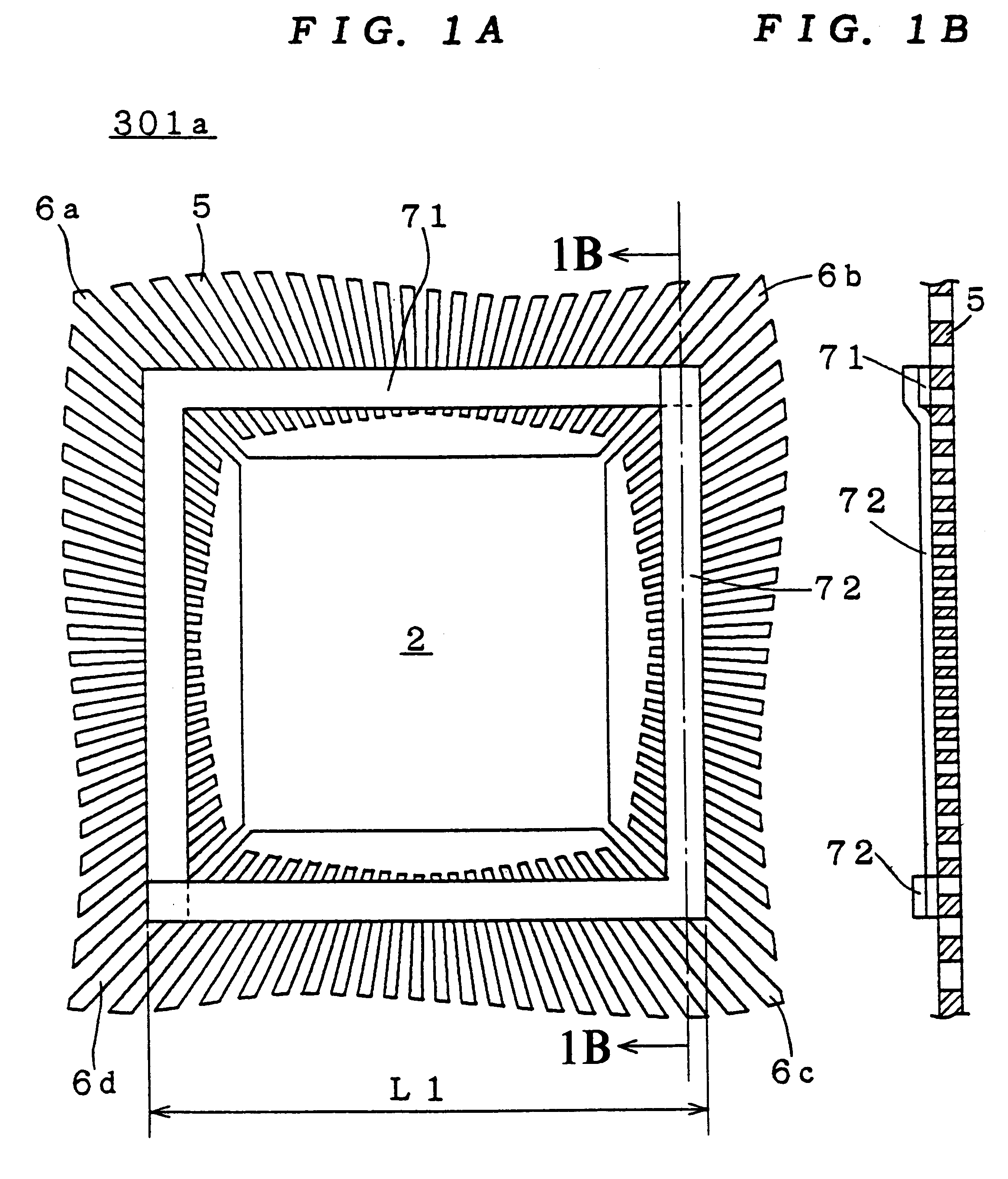

FIG. 1A is plan view of a leadframe 301a is accordance with the first preferred embodiment of the present invention and FIG. 1B is a section taken along the 1B--1B of FIG. 1A and viewed from the direction of the arrow.

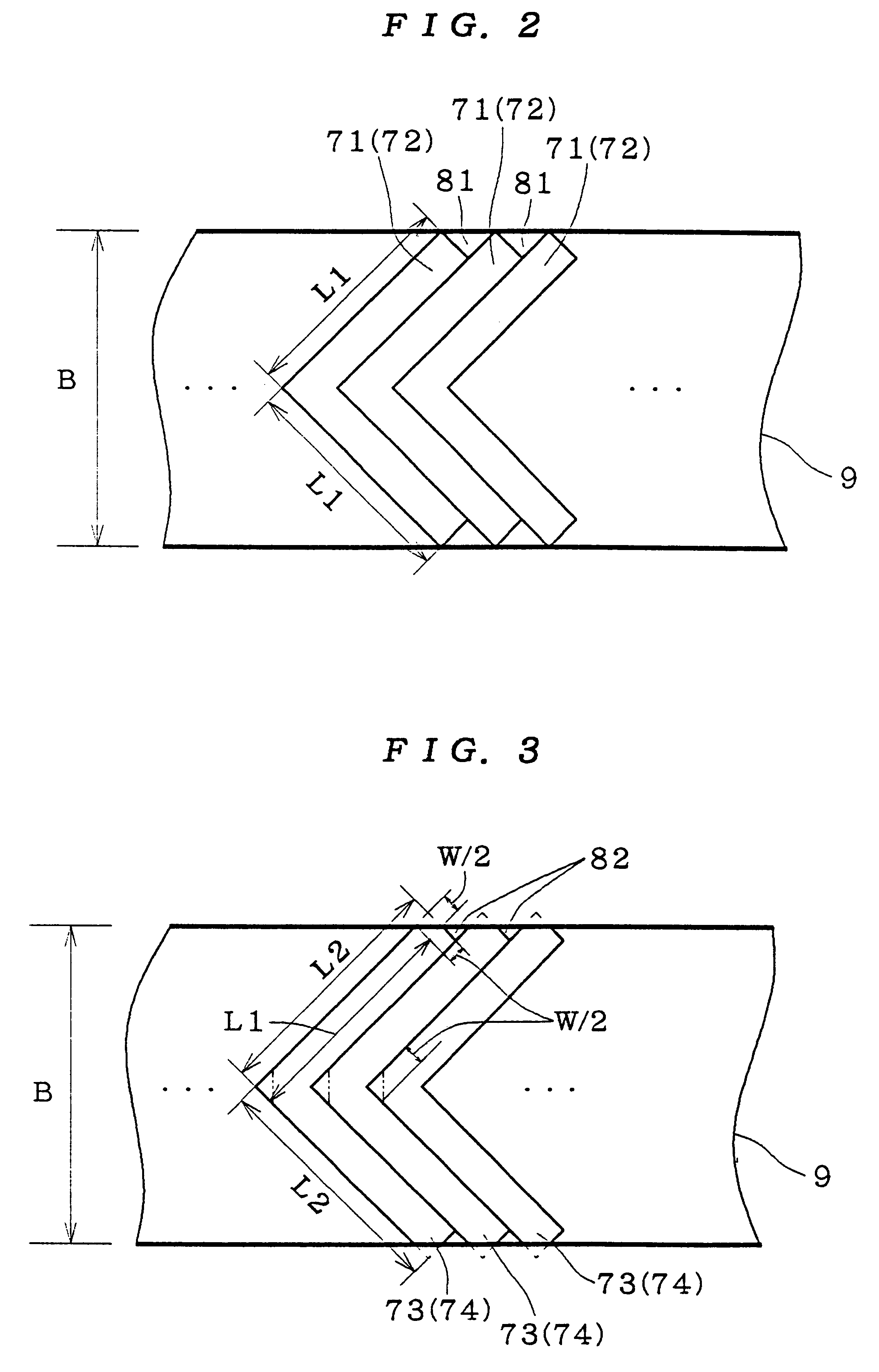

In the leadframe 301a, L-shaped support tapes 71 and 72 are applied to the inner leads 5 and the suspension leads 6a to 6d. End portions of the support tapes 71 and 72 are overlapped with each other at the upper-right suspension lead 6b and the lower-left suspension lead 6d and their vicinities, and thus these two support tapes form together a rectangular ring shaped. That avoids the problem of the second background art structure that the inner leads 5 and the suspension leads 6a to 6d are deformed.

Moreover, since the support tapes 71 and 72 are L-shaped, their center portions and their vicinities are positioned at the suspension leads 6a and 6c and their vicinities, respectively, and there are only two overlapped end portions of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com