Swivel joint with stepped bearing races

a stepped bearing and swivel joint technology, applied in the direction of hose connection, rod connection, mechanical apparatus, etc., can solve the problems of reducing the integrity of the swivel joint, brinelling reducing the life of the bearing race, so as to reduce the weight and cost, improve sealing, and eliminate the brinelling of the bearing race

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

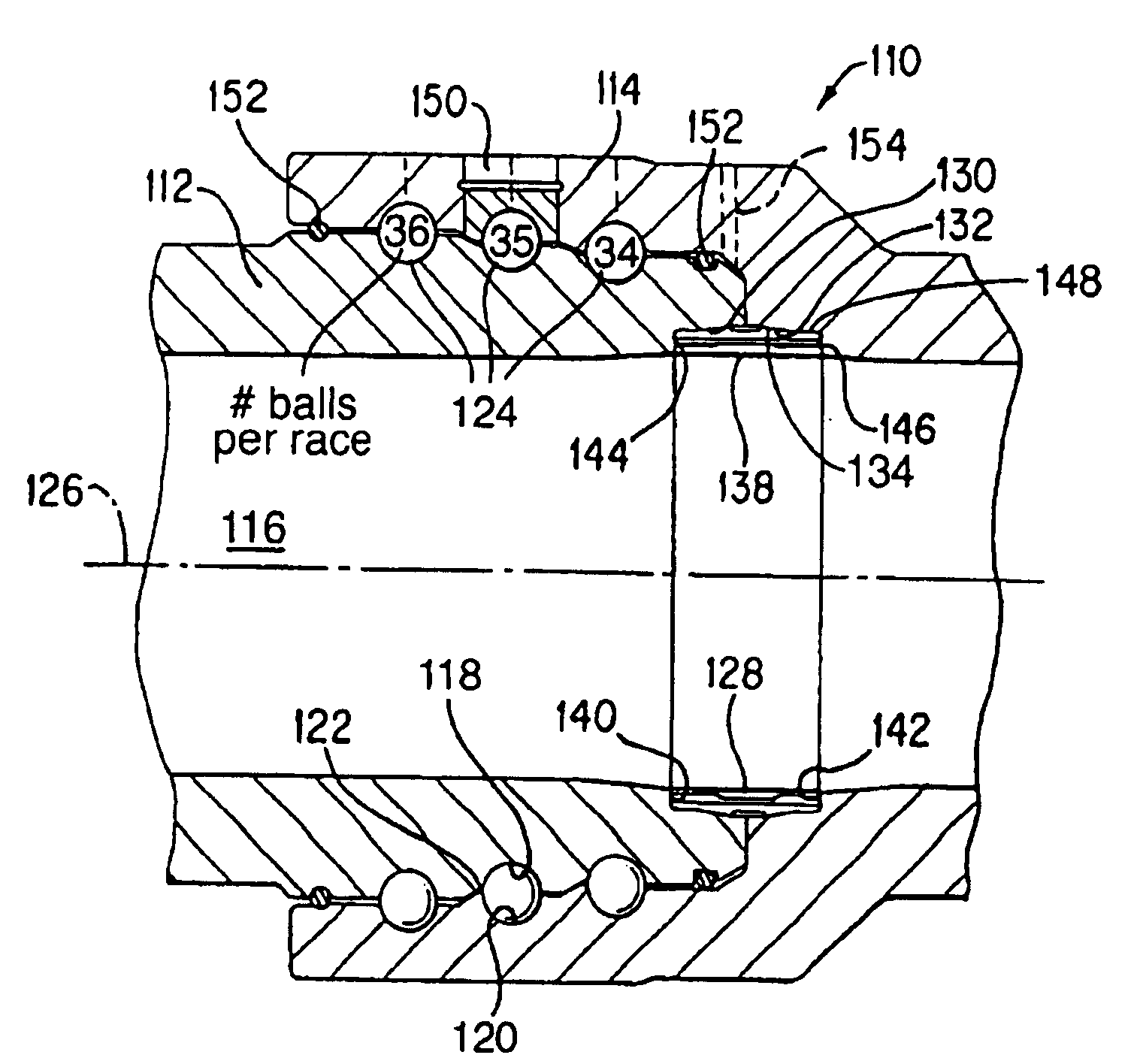

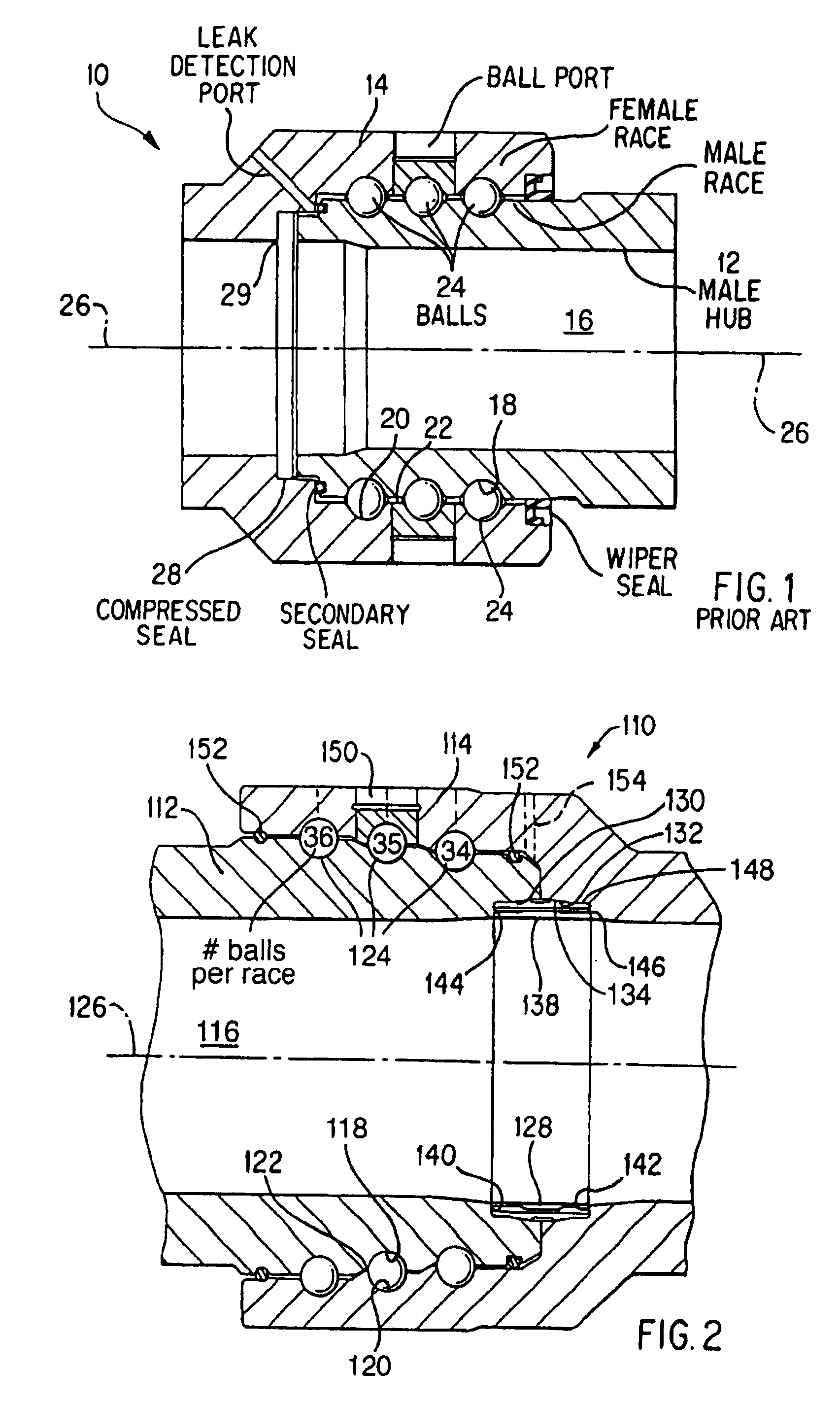

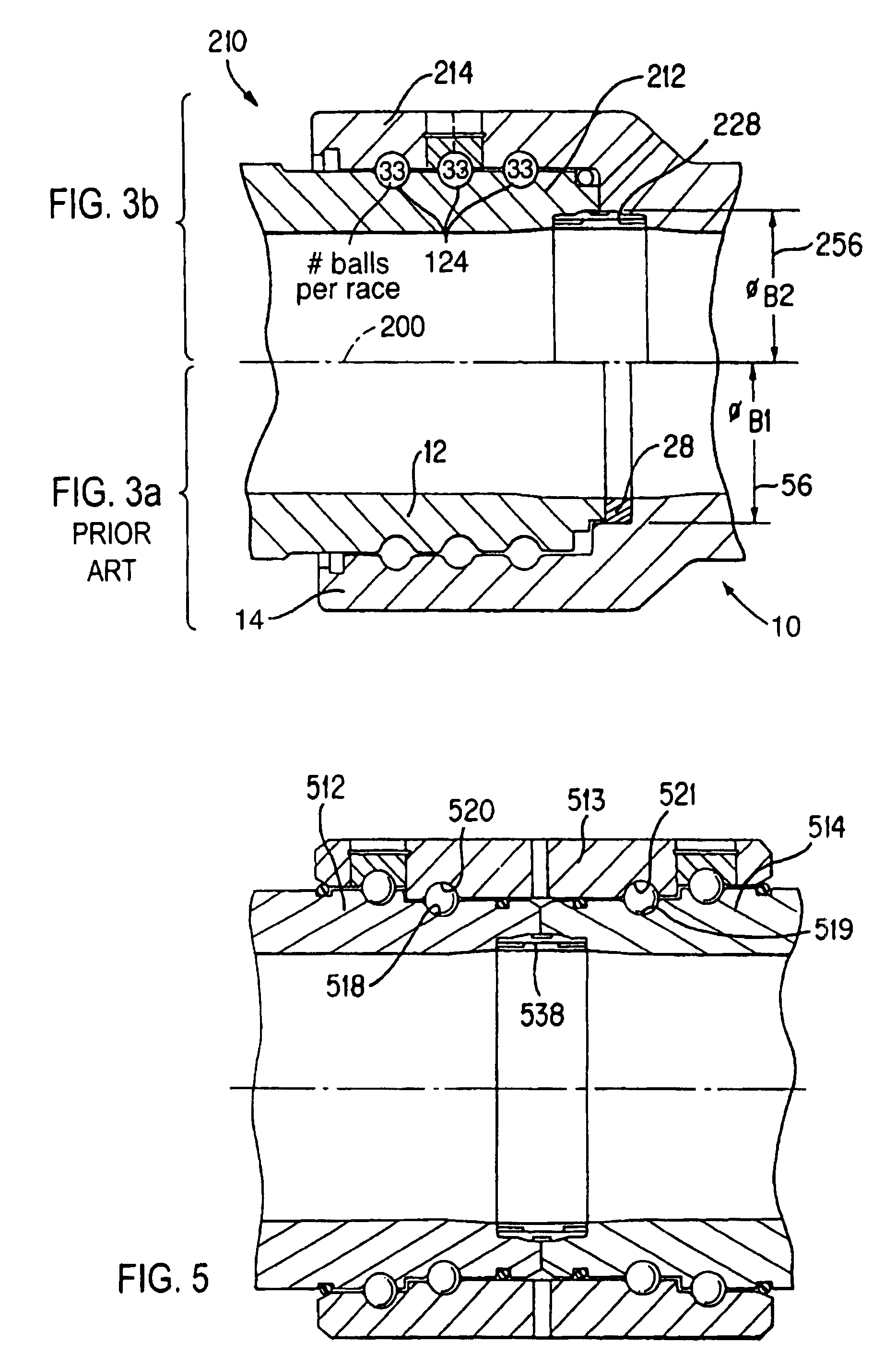

[0014]FIG. 1 shows a known, prior art swivel joint 10 having a male connector 12 rotatably received inside of a female connector 14. A sealed fluid flow passage 16 is formed therethrough, in communication with fluid conduits or pipes (not shown) extending from each connector. Each connector 12, 14 has respectively formed thereon a plurality of annular grooves 18, 20. When the connectors 12 and 14 are inserted together, the grooves 18 and 20 align with each other forming annular bearing races 22. A plurality of ball bearings 24 are housed in each race 22 to provide bearing support and to enable swiveling of the connectors 12, 14 relative to each other. The races 22 and ball bearings 24 are coaxially positioned around a center axis 26 of the flow passage 16. The races 22 all have substantially the same radius. An annular elastomer compression seal 28 is positioned between axial faces of the male connector 12 and the female connector 14 to prevent fluid flow therebetween. The compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com