Seat belt tension prediction

a seat belt and tension prediction technology, applied in the direction of instruments, pedestrian/occupant safety arrangements, force/torque/work measurement apparatus, etc., can solve the problem of complete loss of contact with the seat belt, and achieve the effect of accurate calculation of seat belt tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

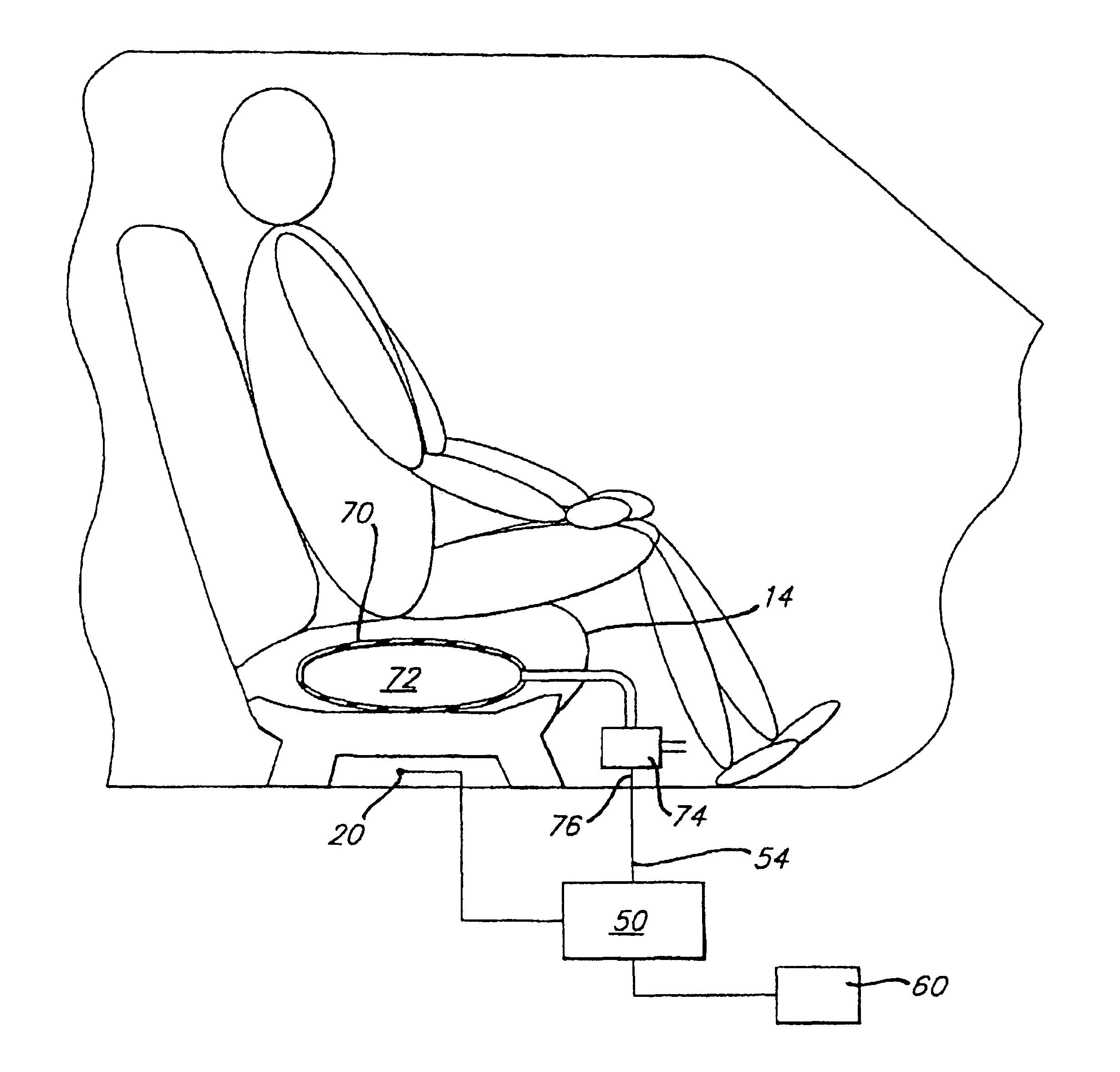

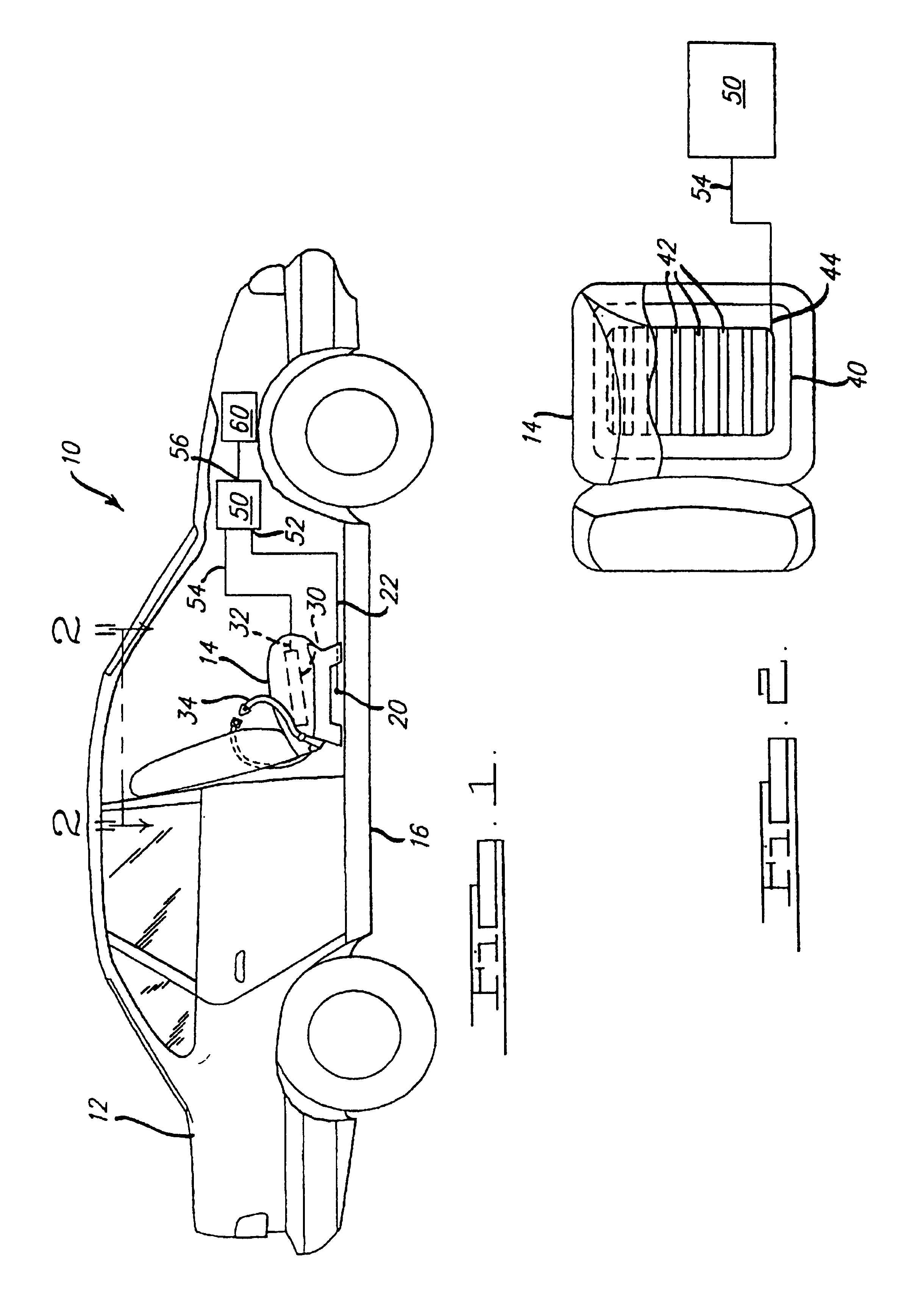

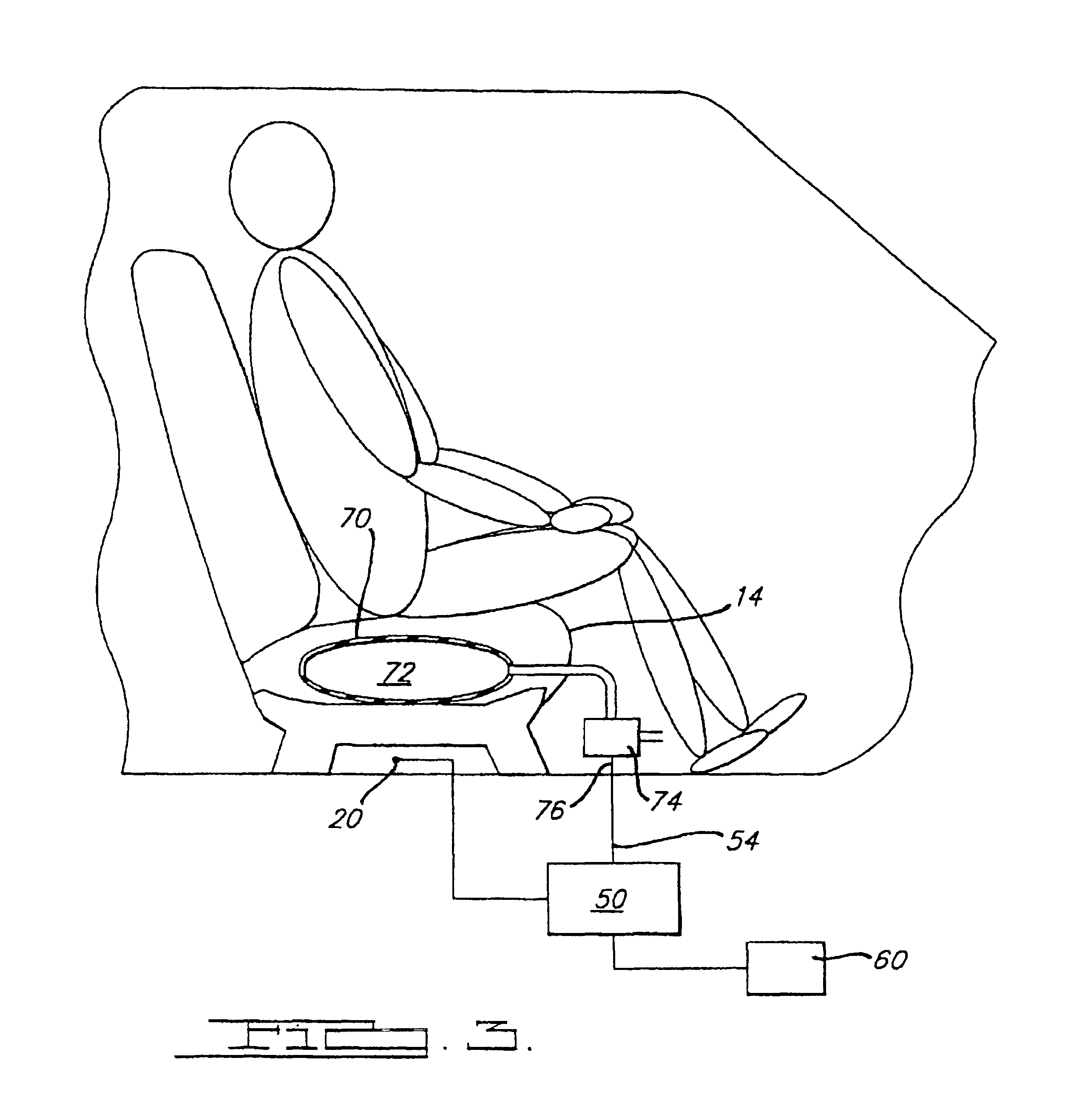

[0043]Referring to FIG. 1, a seat belt tension prediction system and method 10 for a vehicle 12 having a seat 14 is comprised of an accelerometer 20 and a seat weight sensor 30. The accelerometer 20 is provided with an output signal 22 that is responsive to the amount of vertical acceleration acting upon the vehicle 12 and, therefore, on the vehicle seat 14. The accelerometer 20 must be rigidly secured to a vehicle structural member 16 that experiences the same vertical acceleration that the vehicle seat 14 is subjected to when traversing variations in terrain. In a preferred embodiment of the instant invention the resolution of the accelerometer 20 is greater than 0.005 g to provide sufficient sensitivity to small variations in vertical acceleration.

[0044]The seat weight sensor 30 is provided with an output signal 32 that is responsive to the amount of force exerted downwardly on the vehicle seat 14. Accordingly, the seat weight sensor output signal 32 will also be responsive to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| vertical acceleration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com