Belt device

a belt and belt technology, applied in the field of belt devices, can solve problems such as significant belt meandering, and achieve the effect of preventing meandering and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

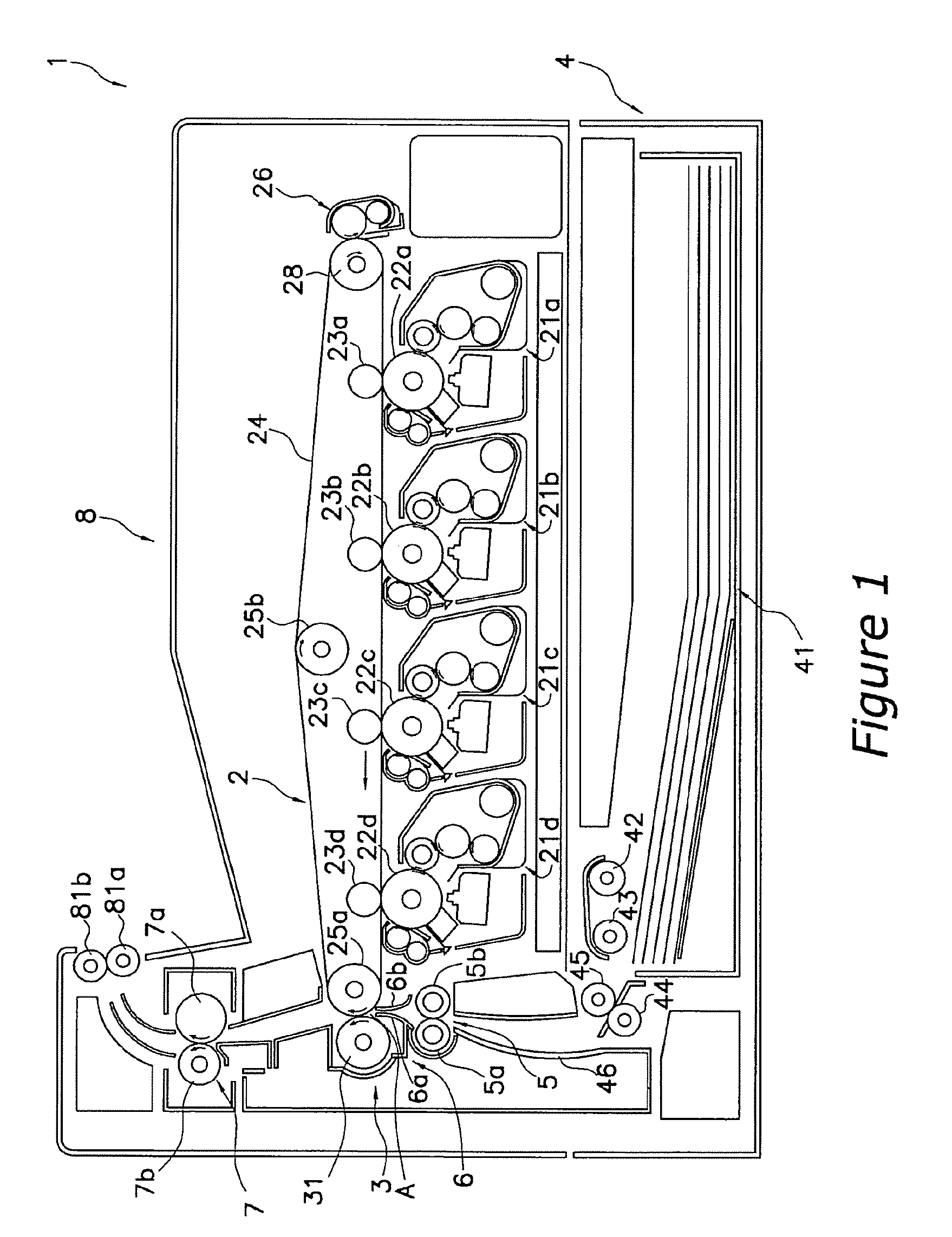

[0018]FIG. 1 is a diagram showing the constitution of the primary portions of a tandem color printer 1 using an embodiment of the present invention. The color printer 1 has an image forming unit 2 that forms a color image, a transfer unit 3 that transfers a toner image formed by the image forming unit 2 to a transfer material, a sheet feed unit 4 that supplies the transfer material, a resist roller unit 5 that synchronizes the transfer material transport and image formation, a transfer material transport guide mechanism 6 that guides transfer material that has reached the resist roller unit 5 to a transfer position, a fuser unit 7 that fuses the toner image transferred to the transfer material, and an output unit 8 that outputs the transfer material.

[0019]The image forming unit 2 is positioned roughly at the center of the color printer, and comprises, corresponding to the four colors of black, yellow, cyan and magenta, four process units 21a, 21b, 21c, 21d, four photosensitive drums...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com