Automatic control valve block of biliquid flow

An automatic control valve and control valve technology, applied in the field of hydraulic devices, can solve the problems of inability to pre-assemble and adjust, there are many seals, and the volume of the control oil cavity is large. road simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The control valve block 5 of the present invention is applied to a hydraulic grab.

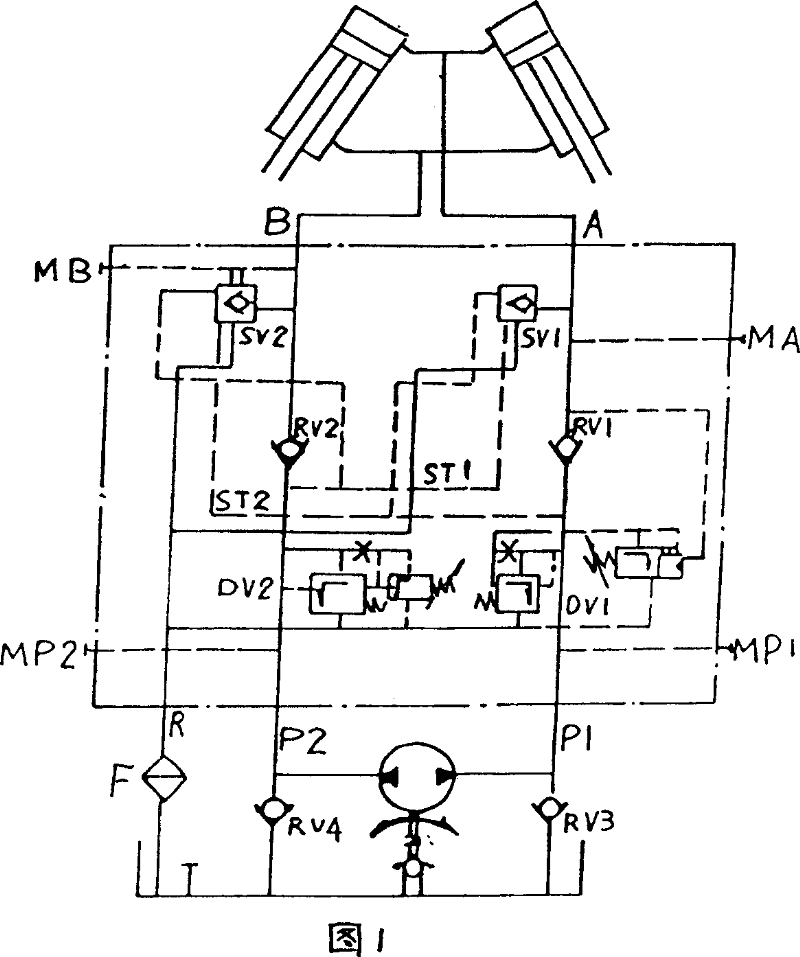

[0027] As shown in Figure 9, the hydraulic grab generally consists of an electric motor 1, a two-way hydraulic pump 2, two oil suction check valves 3 directly mounted on the oil suction port of the two-way hydraulic pump, an oil return filter 4, and an oil return filter 4 of the present invention. The control valve block 5, at least one oil cylinder 6 (the number of oil cylinders is the same as the number of claws), and hydraulic components such as oil pipes, joints, and oil tanks for connection. The hydraulic control principle is shown in Figure 10.

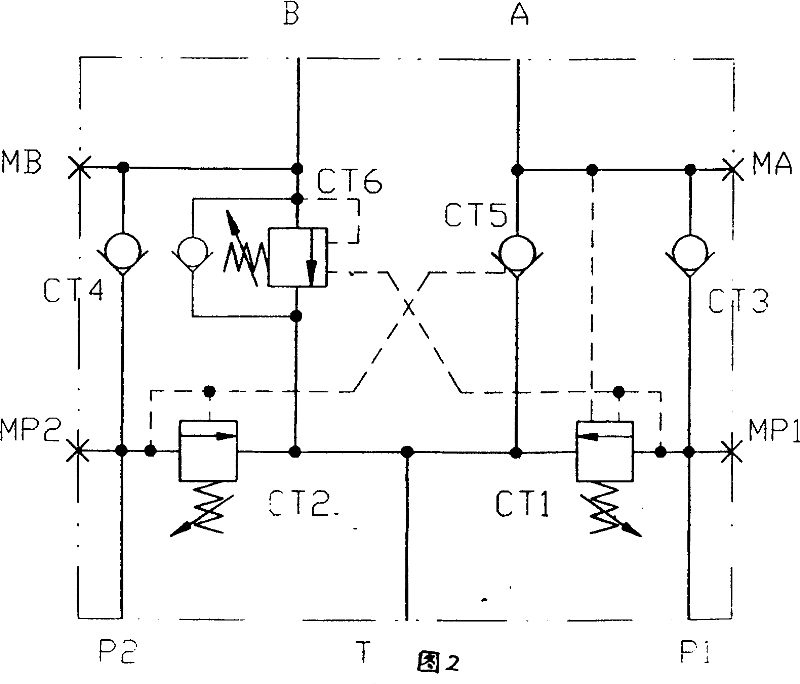

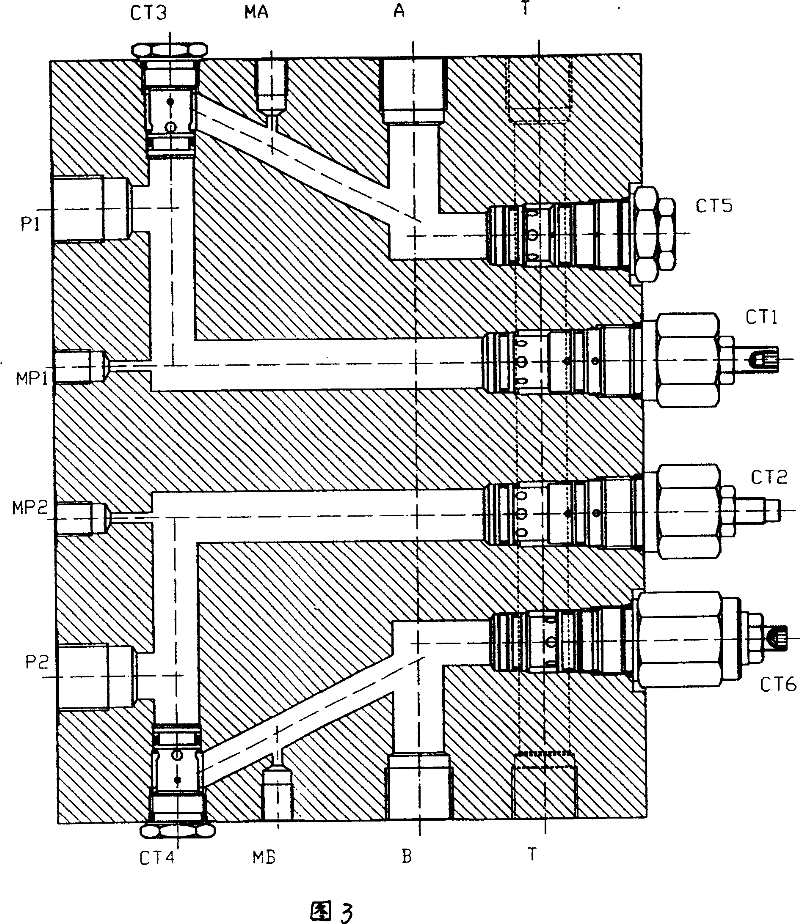

[0028]The control valve block 5 consists of a valve body 11, a pilot unloading relief valve CT1, a pilot relief valve CT2, two check valves CT3 and CT4, a hydraulic control check valve CT5, and a load holding valve CT6. Composed of six valve parts, there are five external main oil ports on the valve body 11, which are two o...

Embodiment 2

[0033] Embodiment 2: The control valve block 5 of the present invention can also be applied to the opening and closing device of the port spreader, and the starting device of the port and inland river sluice. The control method is similar to the hydraulic grab, except that the object is changed from the paw to the gate. and other devices, the hydraulic control principle is shown in Figure 9, which is consistent with the hydraulic grab and will not be repeated.

Embodiment 3

[0034] Embodiment 3: The control valve block 5 of the present invention is applied to drilling machinery to drive drill bits, and is applied to rotary machinery such as construction machinery chassis. The hydraulic control principle is shown in FIG. 10 .

[0035] The hydraulic power supply and control method used to drive the drill bit on drilling machinery basically adopts the method of one-way hydraulic pump and reversing valve. After adopting the hydraulic control principle shown in Figure 10, the purpose of working process control such as drill bit drilling and reverse replacement of drill rods can be achieved by changing the direction of the motor. The control principle inside the control valve block 5 is shown in FIG. 9 . The difference is that the oil port B is used as the power oil port for normal drilling, providing a lower working protection pressure, and the oil port A is used as the power oil source port for dismantling the drill pipe, which can provide an oil sour...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap