Socket device for electric parts

A technology of electrical components and sockets, which is applied in the direction of coupling devices, electrical components, incandescent lamp parts, etc., can solve the problems of reduced reliability of socket devices and weak elastic force of contact terminals 11, and achieve miniaturization, prevention of deformation of contact terminals, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the best mode for implementing the electrical component socket device related to the present invention will be described based on the drawings.

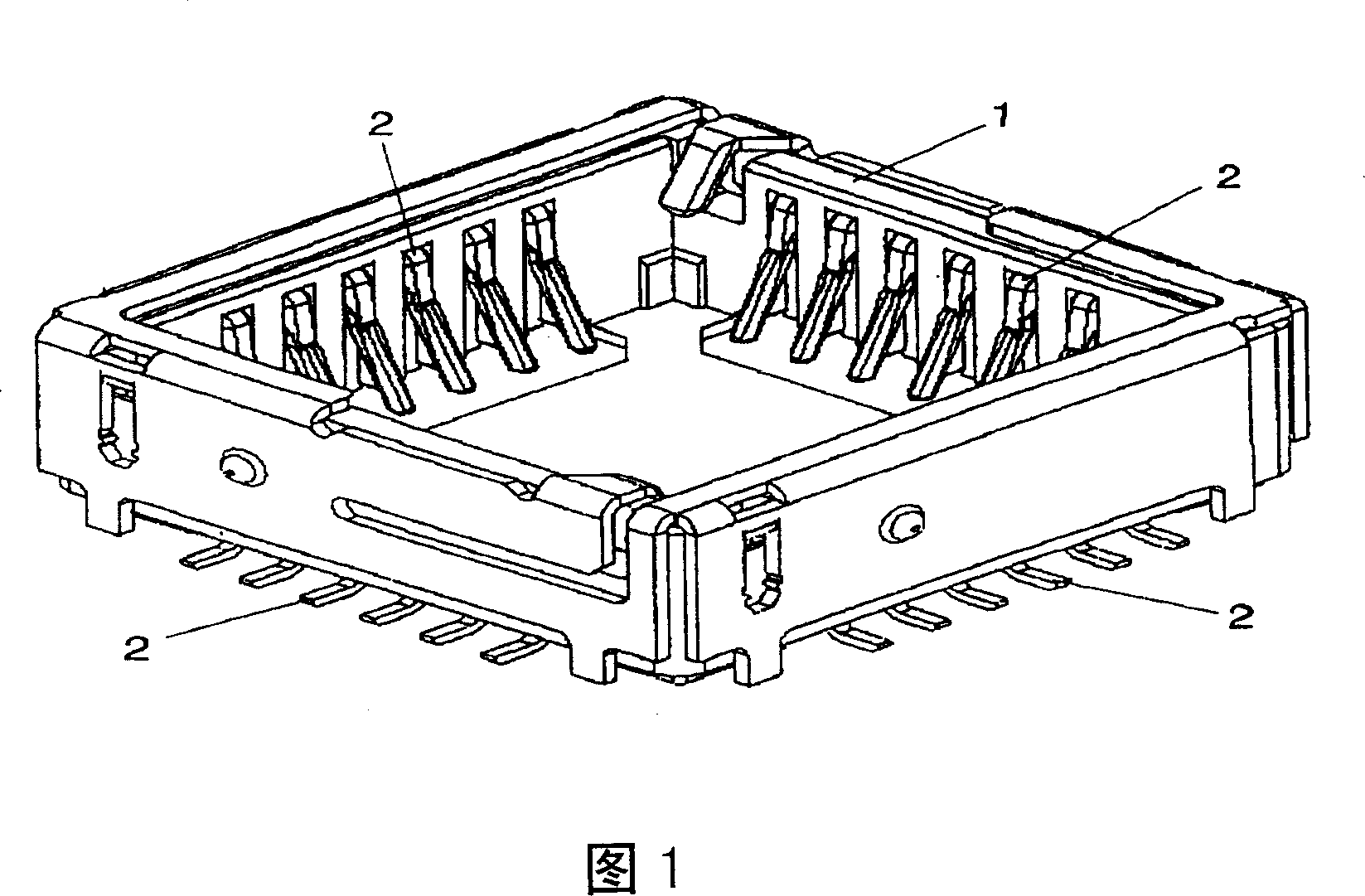

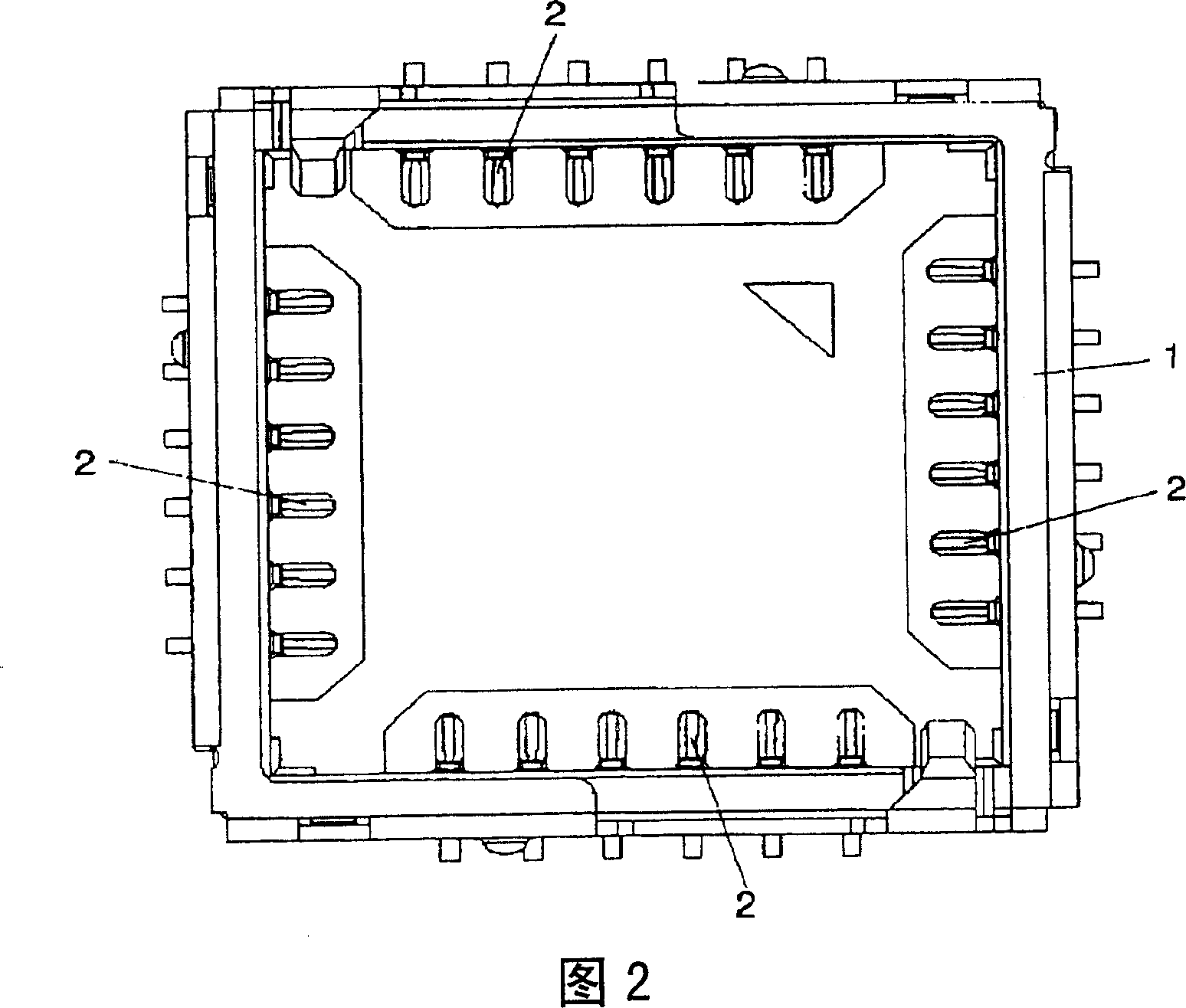

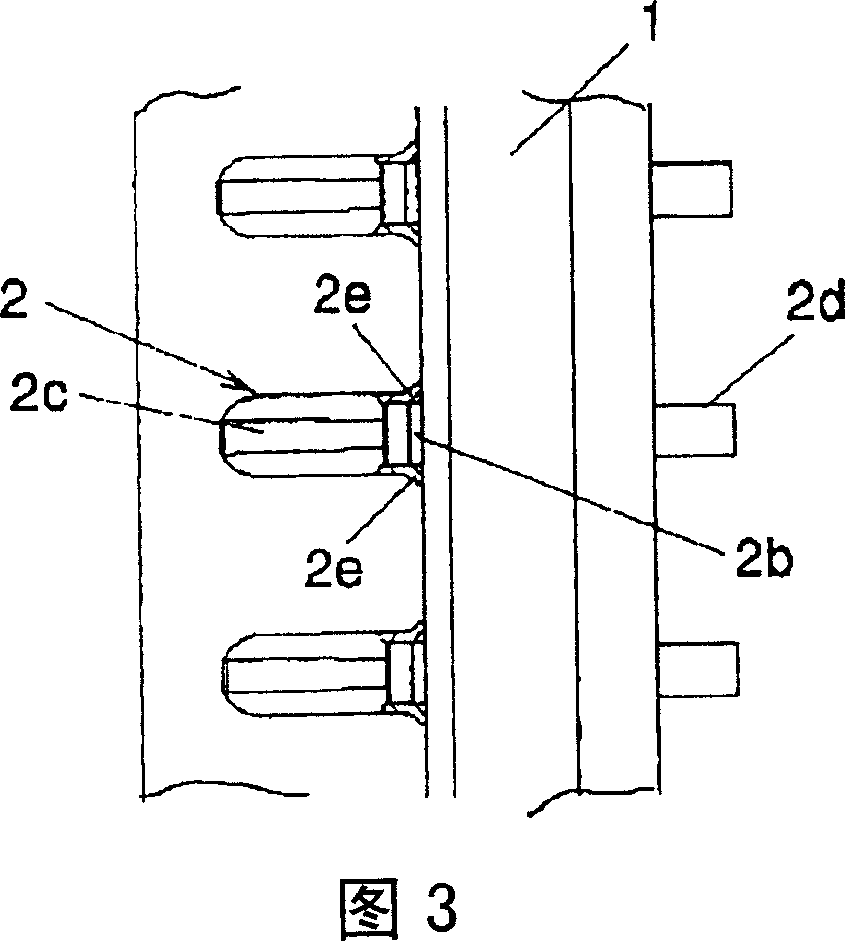

[0032] Fig. 1 is a perspective view of an embodiment of the present invention, Fig. 2 is a plan view of the embodiment shown in Fig. 1, and Fig. 3 is a partial enlarged schematic view of Fig. 2. Fig. 4 is a longitudinal sectional view of the embodiment shown in Fig. 1, and Fig. 5 is a partial enlarged schematic view of Fig. 4. Fig. 6 is an explanatory view of the contact terminal included in the embodiment shown in Fig. 1, in which (a) is a plan view, (b) is a front view, (c) is a perspective view, and (d) is a side view .

[0033] As shown in FIGS. 1 to 5, in the present embodiment, for example, there is a housing 1 whose overall shape is a square. The four inner walls of the housing 1 respectively have grooves 4 with electrical components 3 described later. The contact portion 5 is in contact with a plurality of contact te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com