Hypercritical soluble propolis prescription and its preparing method

A technology of supercritical and propolis liquid, applied in the field of medicine and chemical industry, can solve the problems of difficult high-end products, high residual solvent and high ethanol content, and achieve the effects of no solvent residue, good solubility and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

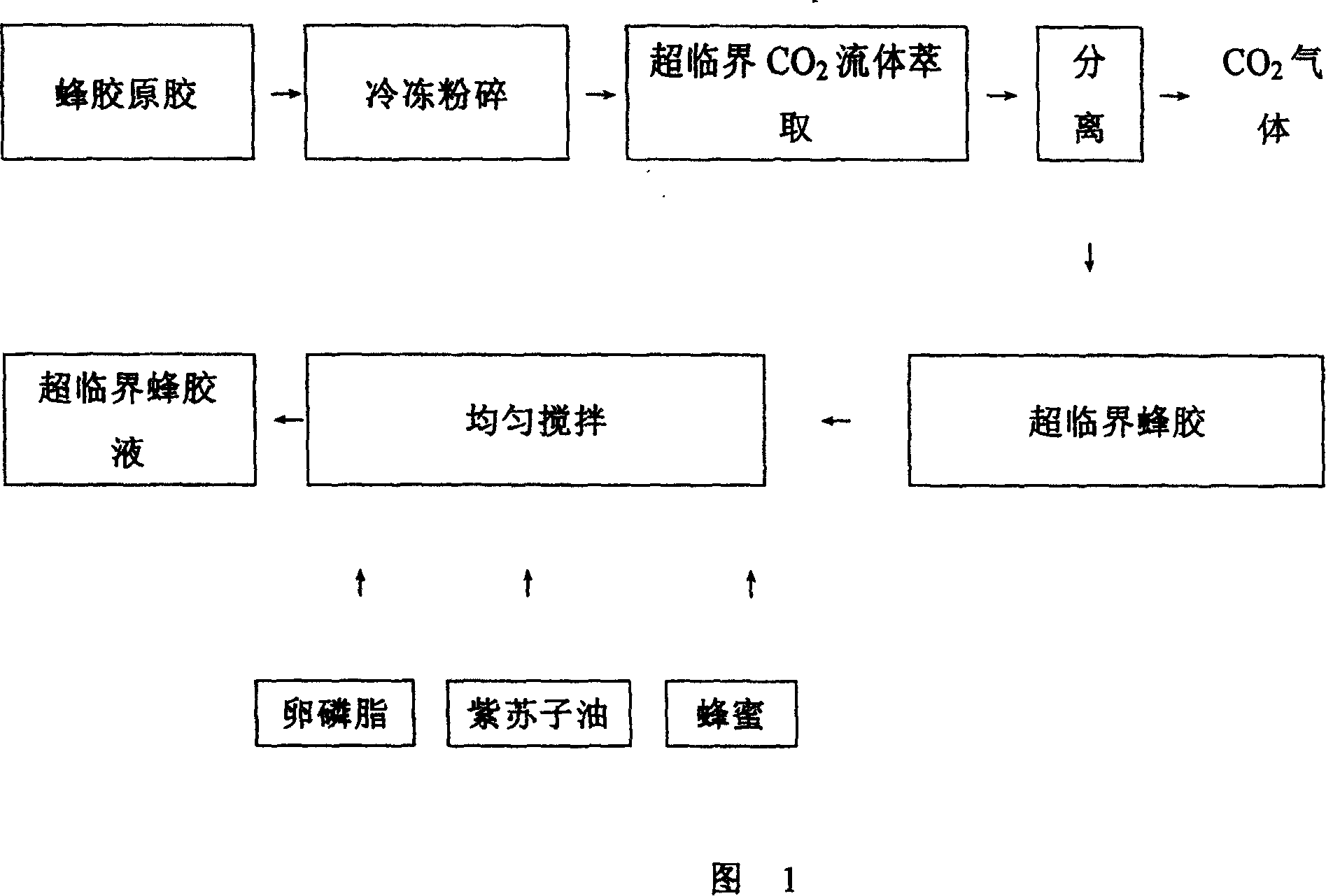

[0015] Supercritical CO 2 Fluid extraction method extracts pure supercritical propolis liquid from propolis liquid, then with 5% supercritical propolis liquid, 5% perilla seed oil, 2% lecithin, 88% honey (percentage by weight, The same below) is put into the blender and stirred by ultrasonic or mechanical device until it becomes a very uniform soluble propolis liquid.

Embodiment approach 2

[0017] Supercritical CO 2 Fluid extraction method, extract pure supercritical propolis liquid from propolis liquid, then put 10% supercritical propolis liquid, 15% perilla seed oil, 6% lecithin, 69% honey into the blender, Use ultrasonic or mechanical device to stir until it becomes a very uniform soluble propolis liquid.

Embodiment approach 3

[0019] Supercritical CO 2 Fluid extraction method, extract pure supercritical propolis liquid from propolis liquid, then put 15% supercritical propolis liquid, 20% perilla seed oil, 10% lecithin, 55% honey into the blender, Use ultrasonic or mechanical device to stir until it becomes a very uniform soluble propolis liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com