Sewing-up side-cutting sewing machine

A tooling and trimming technology, which is applied to sewing equipment, sewing machine components, leather product sewing machines, etc., can solve the problems of low production efficiency, easy waste products, labor and time-consuming, etc., and achieve the effect of improving production efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

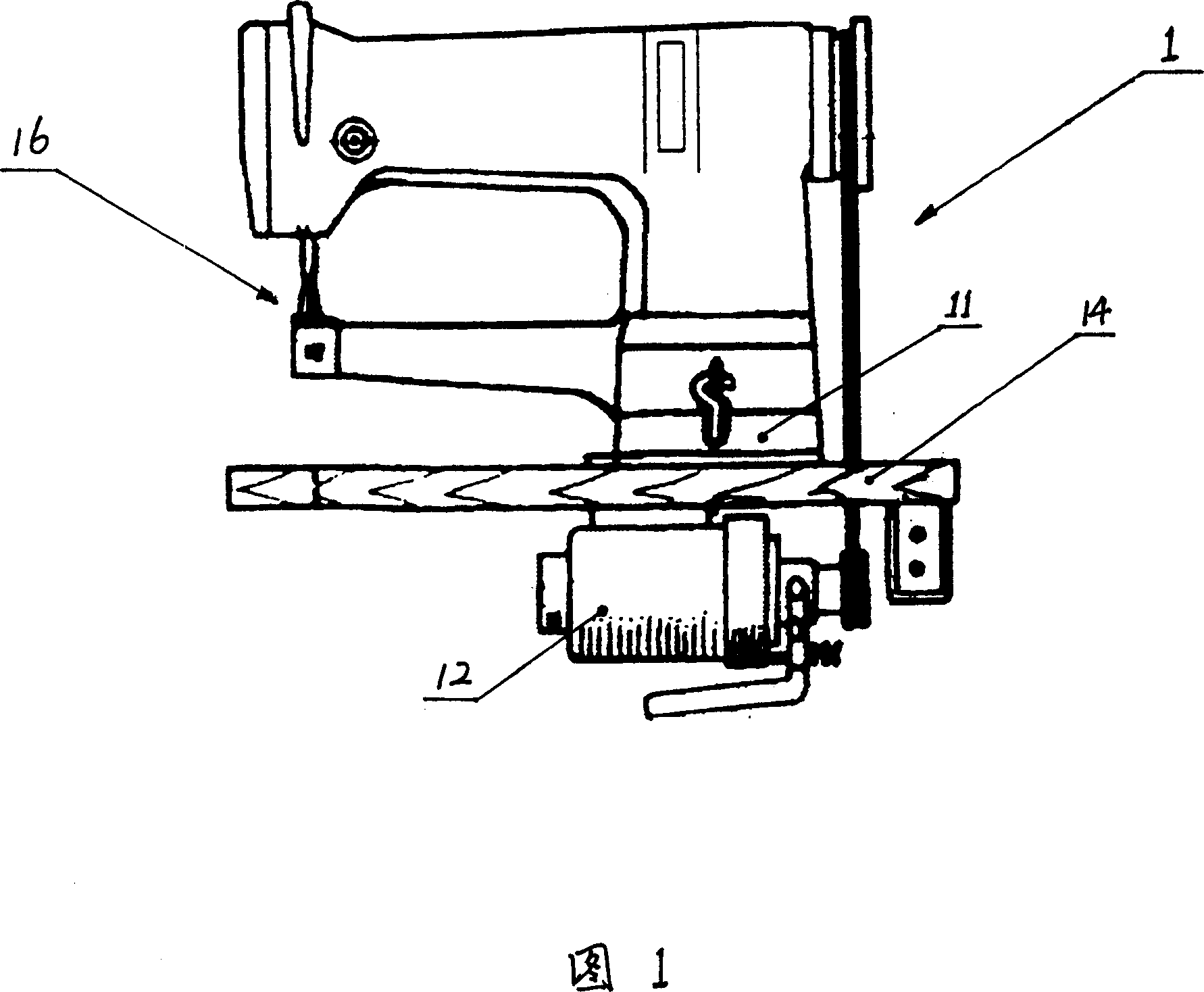

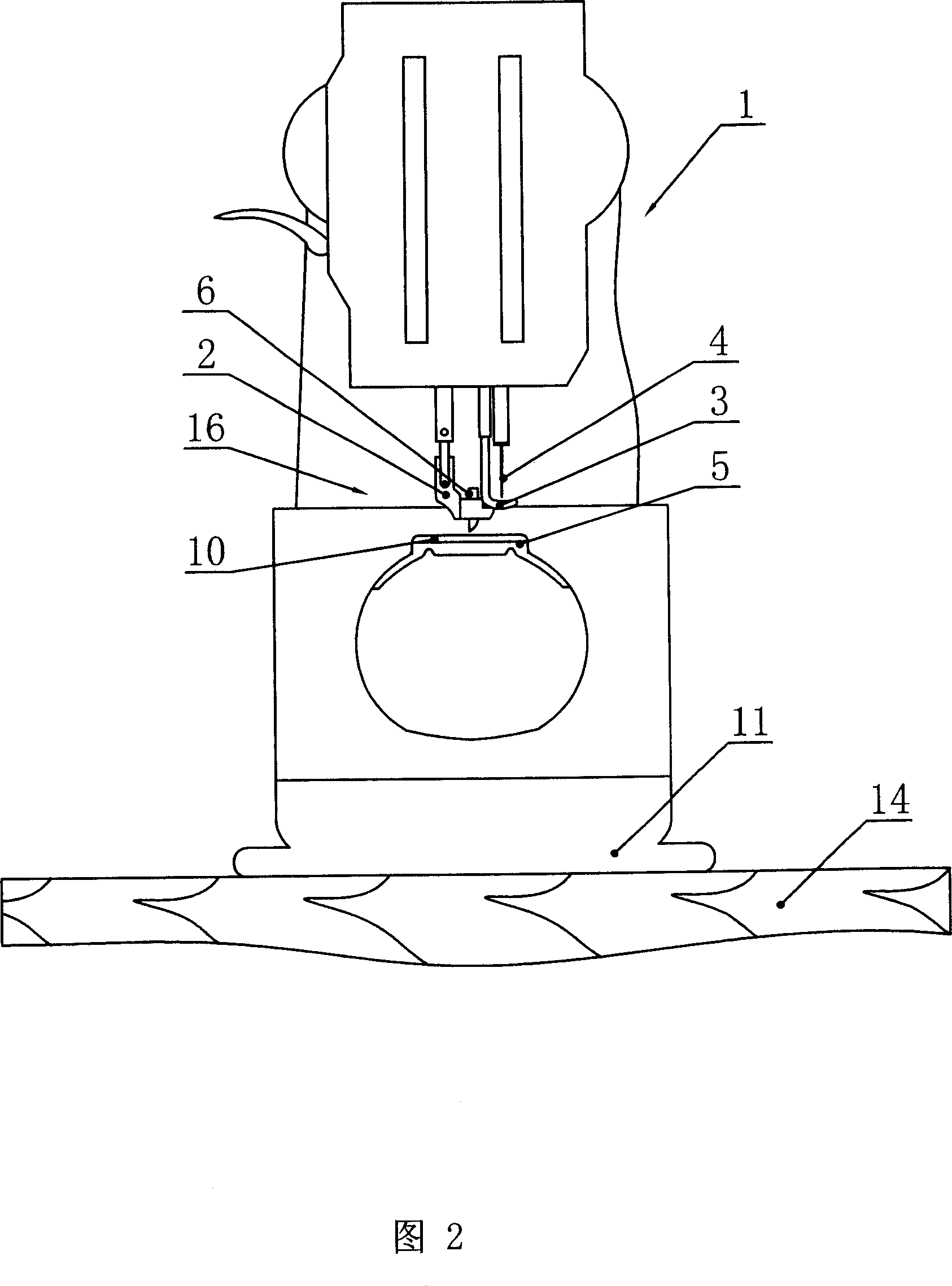

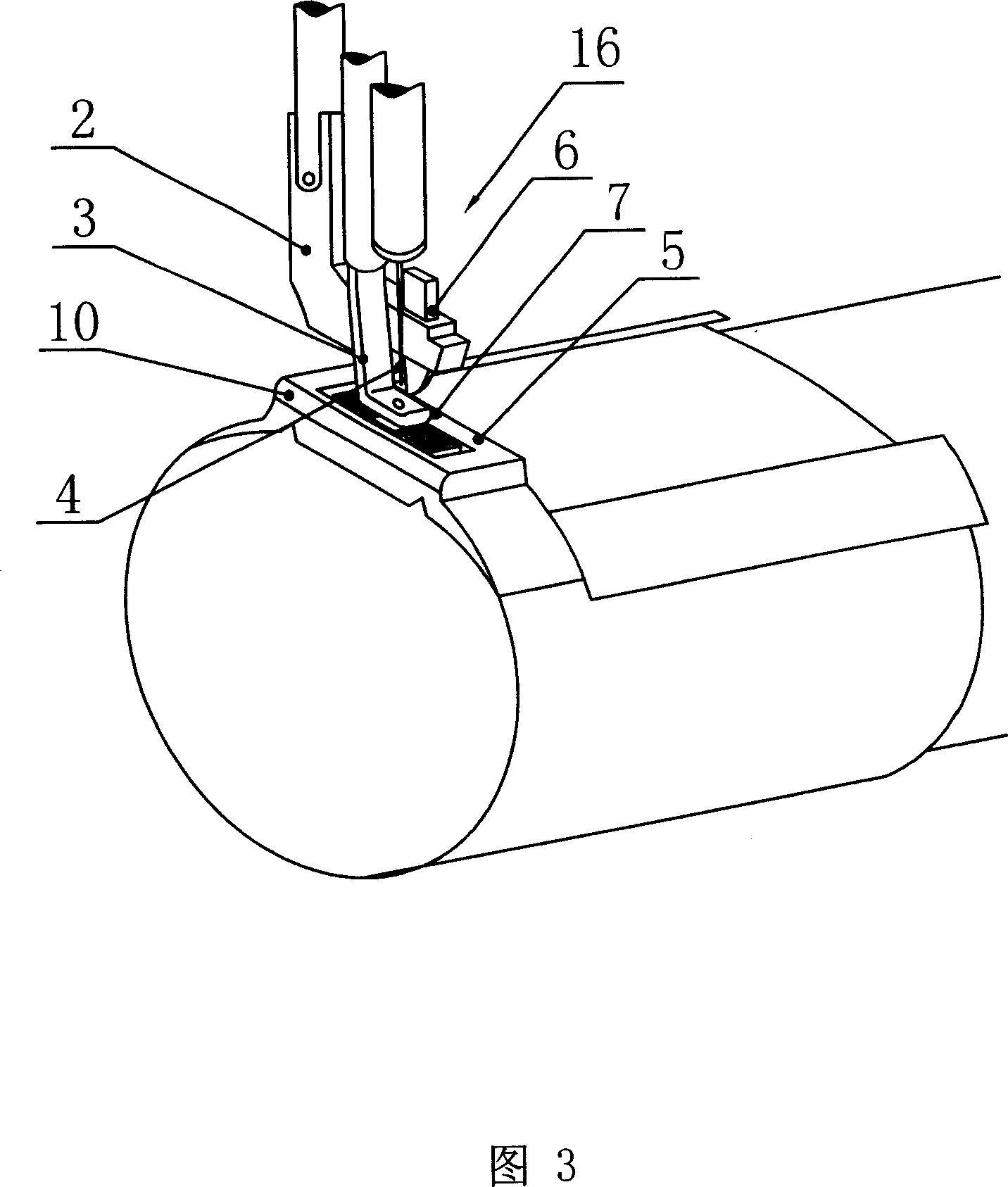

[0029] Embodiment: See accompanying drawing 1~shown in accompanying drawing 3, a kind of suturing trimming frock, this frock equipment is refitted from the standard sewing machine Wanping Machinery Co., Ltd. The tooling equipment includes a machine head 1 and a machine base 11. The machine head 1 is equipped with a thread take-up mechanism, a needle bar swing mechanism, a pressing rod and a pull bar mechanism, an upper feeding mechanism, a lower feeding mechanism, a hook mechanism and a thread passing mechanism, and the machine base 11 A motor 12 and a pedal are installed at the lower part, a large presser foot 2, a small presser foot 3 and a machine needle 4 are arranged above the suture 16 of the machine head 1, and a needle plate 5 is arranged below, and the outer side of the needle plate 5 transitions with an arc angle 10 , the lower end of the large presser foot 2 is provided with a cutting knife 6, which is parallel to the needle line of the machine needle 4, and is posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com