Vehicle body structure

A car body structure and door technology, applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem of increasing the number of parts, making it difficult to give the seat belt reinforcement 4 rigidity, and the outer panel 3 tensile rigidity is easy to decrease and other problems, to achieve the effect of improving tensile rigidity, improving installation rigidity, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

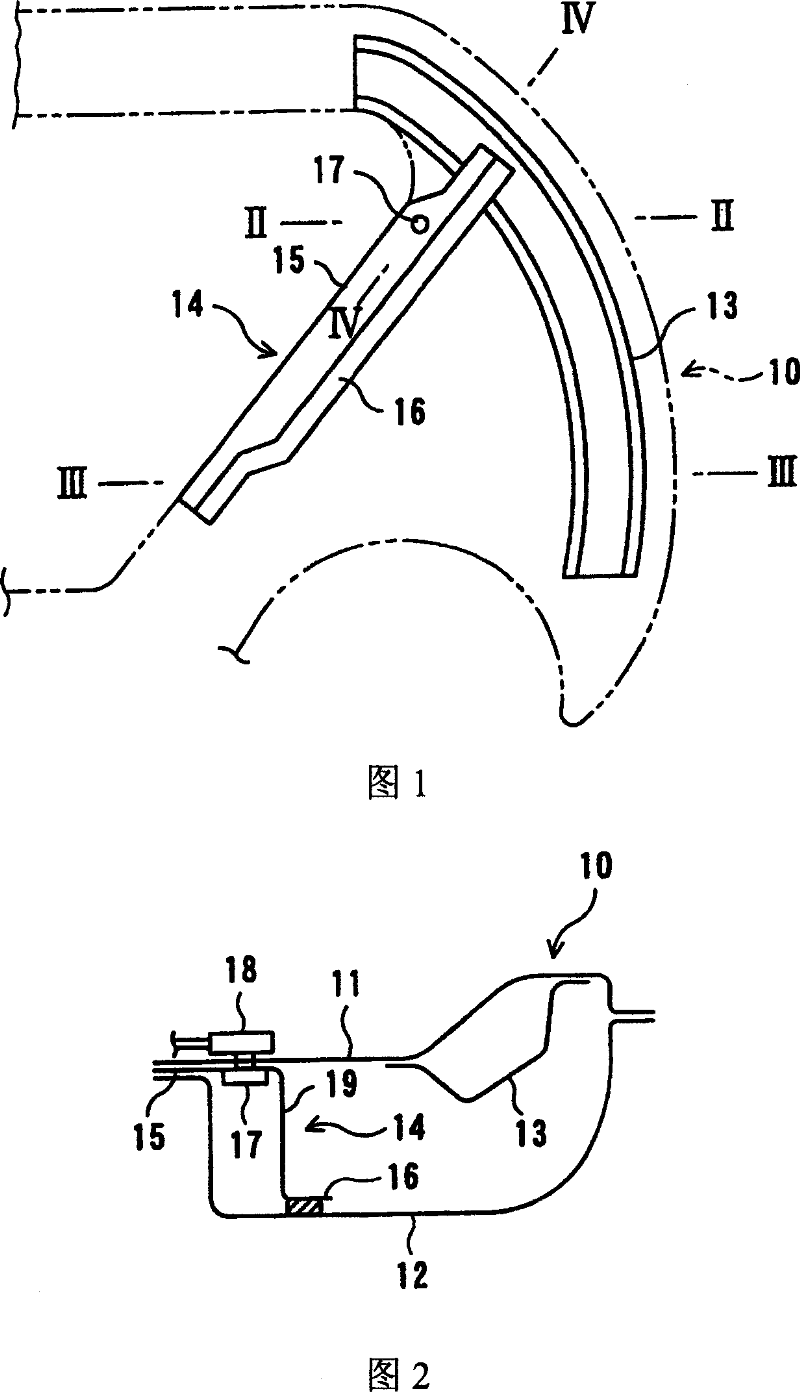

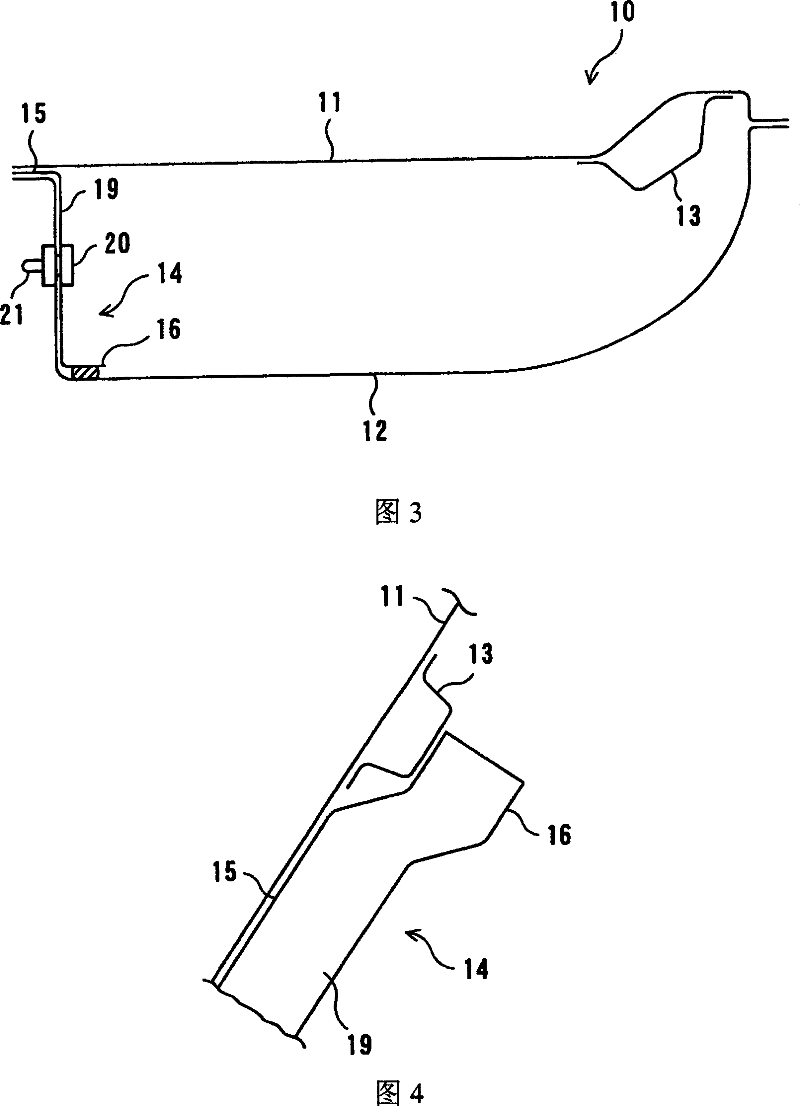

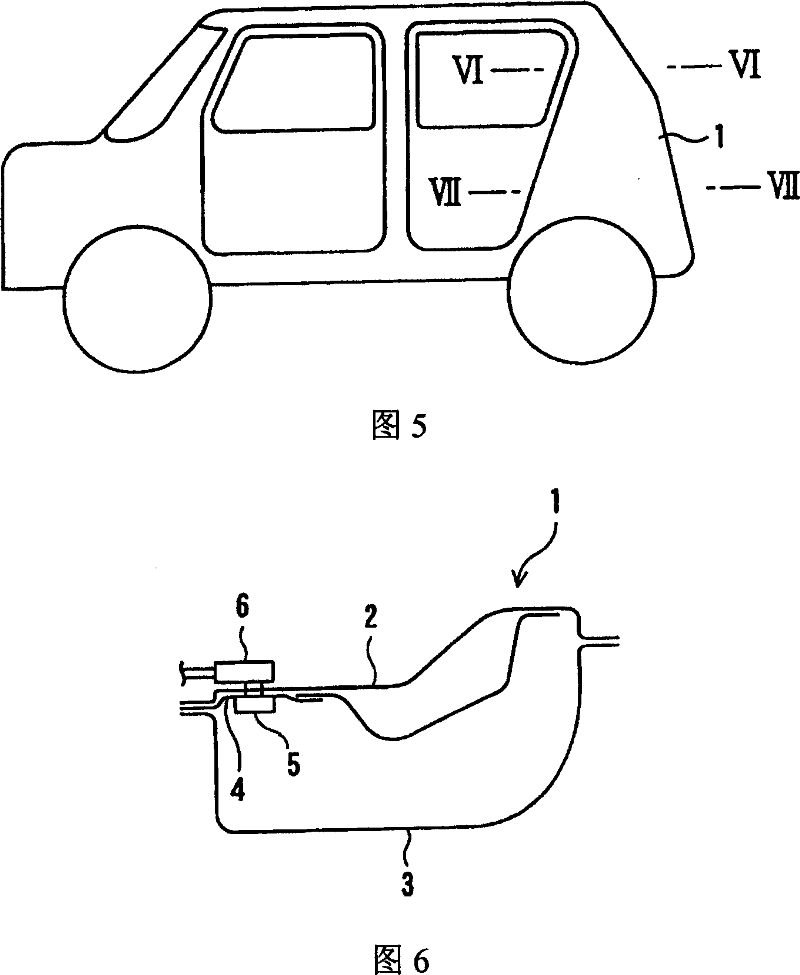

[0027] In FIGS. 1 to 4 , the left and right rear pillars 10 of the vehicle are respectively welded to the edges (Japanese: フランジ) of the inner panel 11 and the outer panel 12 to form a closed section. The rear pillar reinforcement 13 extending in the vertical direction.

[0028] The reinforcement member 14 has a substantially Z-shaped cross-section formed by the vehicle front side edge portion 15, the vehicle rear side edge portion 16, and the middle portion 19 connecting the two edge portions 15, 16 in the substantially vehicle width direction, so as to extend along the rear pillar 10. The vehicle front side end edge extends downward in the vehicle front direction, and is arranged in the rear pillar 10 obliquely relative to the vertical direction, and the vehicle front side edge portion 15 is sandwiched between the two edge portions of the inner panel 11 and the outer panel 12. On the other hand, the vehicle rear side edge portion 16 is joined to the inner surface of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com