Engine supporting structure for working vehicle

a technology for working vehicles and supporting structures, which is applied in the direction of electric propulsion mounting, jet propulsion mounting, transportation and packaging, etc., can solve the problems of high production costs, increase in the number of components, and complicated manufacturing processes, so as to improve the bending rigidity of the mounting plate, eliminate the structure, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

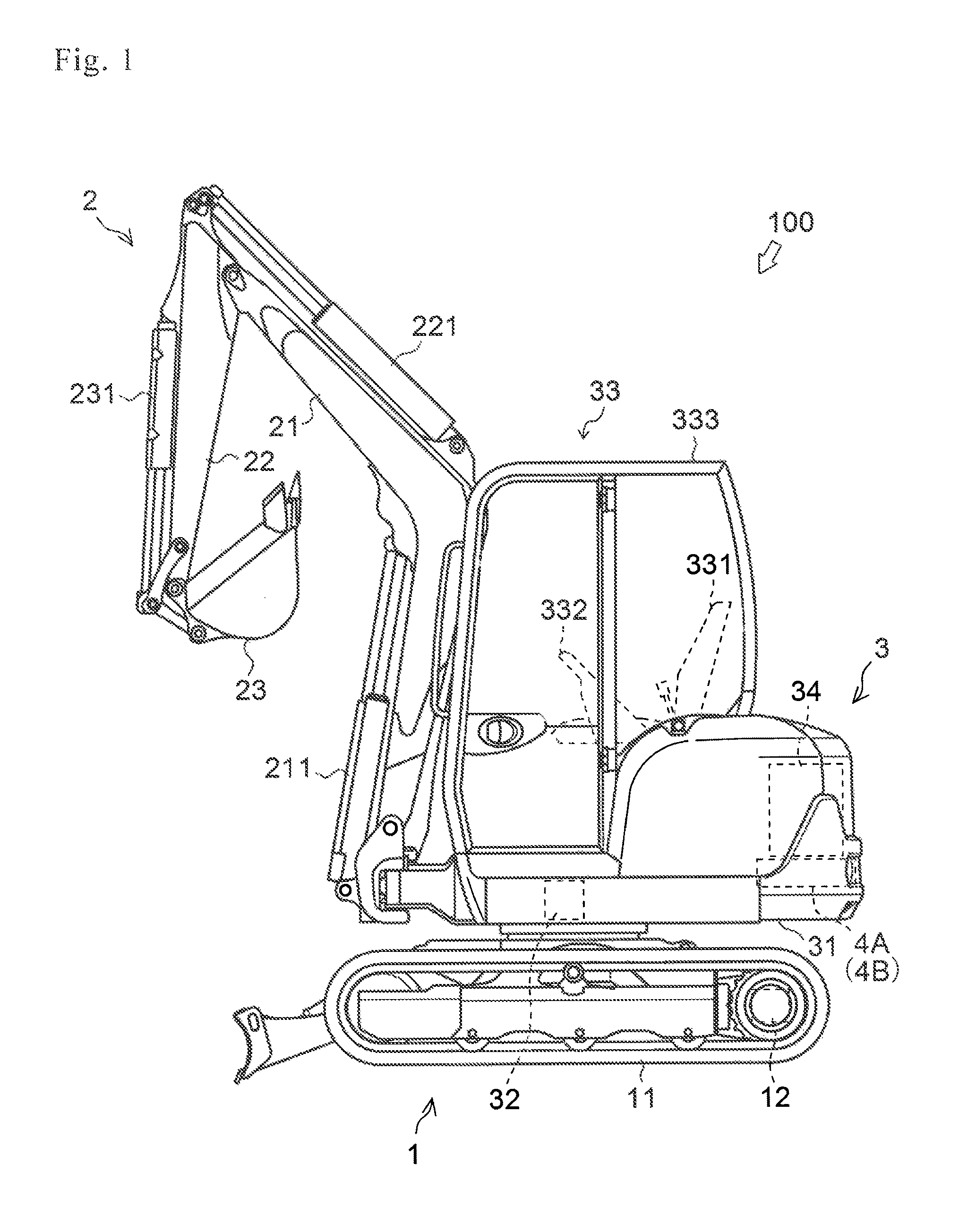

[0034]Hereinafter, the engine supporting structure 4 (hereinafter referred to as “engine supporting structure 4A”) according to the present invention will be described in detail.

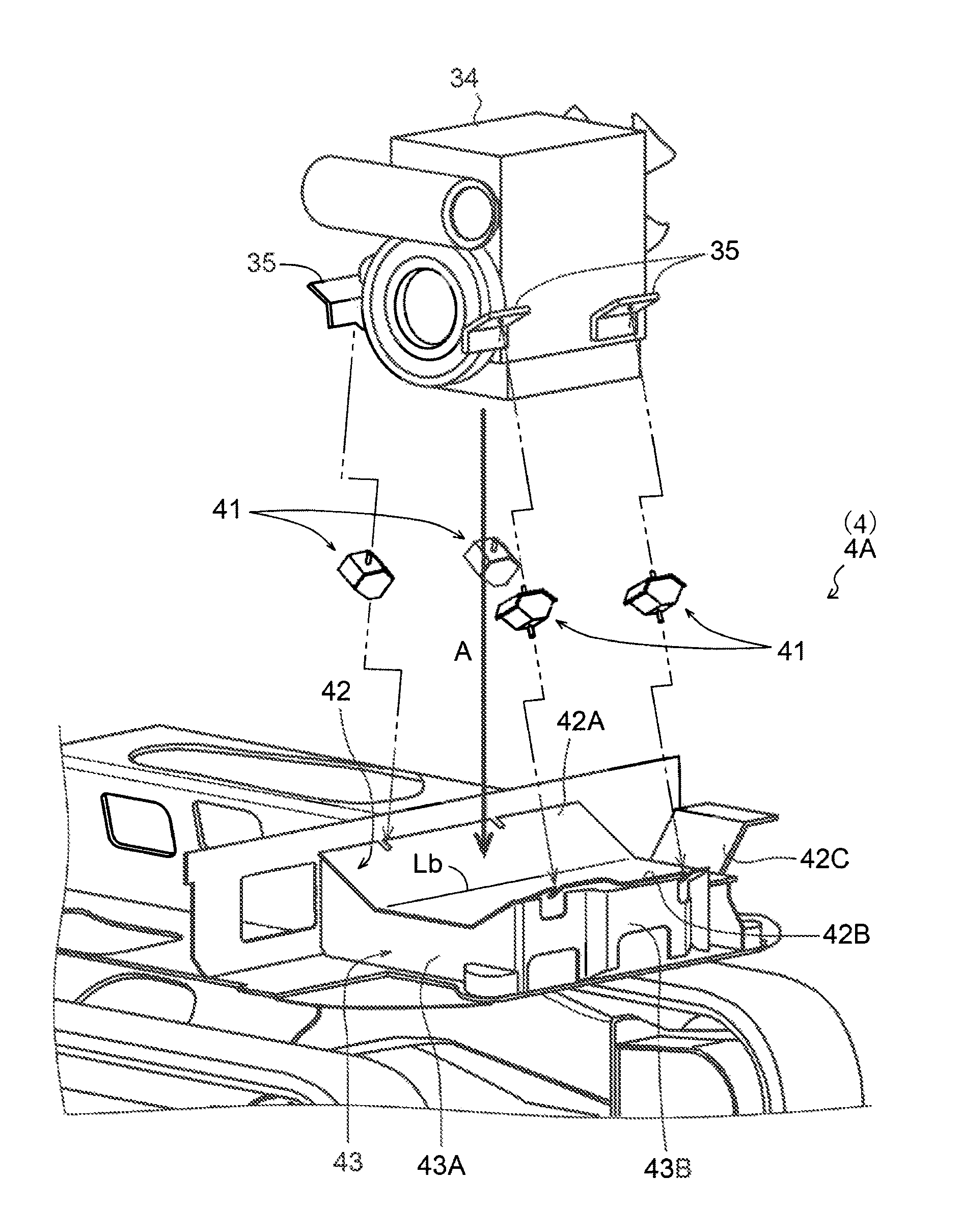

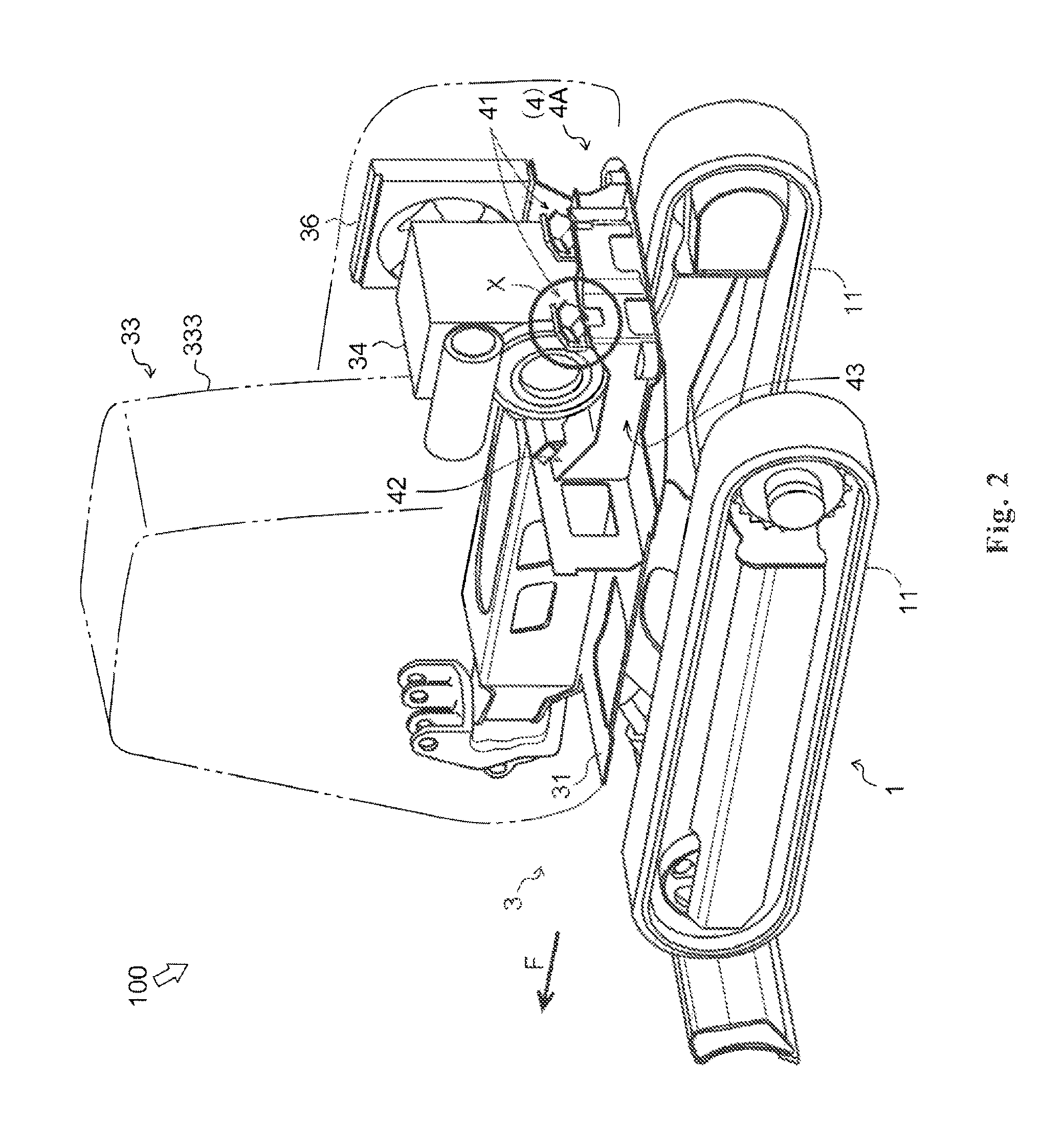

[0035]FIG. 2 is a diagram illustrating the engine supporting structure 4A according to the first embodiment of the present invention. FIG. 3 is an enlarged view of an area X of FIG. 2. Then, FIG. 4 is a diagram illustrating the process of mounting the engine 34. It is noted that an arrow F in FIG. 2 represents the advancing direction of the backhoe 100. Also, an arrow A illustrated FIG. 4 represents a mounting direction when the engine 34 is mounted. Further, a thin line Lb illustrated in FIG. 4 represents a bending line of a mount plate 42.

[0036]As is illustrated in FIG. 2, the engine supporting structure 4A is mainly constituted by an engine mount 41 and the mount plate 42.

[0037]As is illustrated in FIG. 3, the engine mount 41 is constituted by a vibration isolation rubber 41R and attaching bolts 41B. The ...

second embodiment

[0045]Next, an engine supporting structure 4 (hereinafter referred to as “engine supporting structure 4B”) according to the present invention will be described in detail.

[0046]FIG. 5 is a diagram illustrating the engine supporting structure 4B according to the second embodiment of the present invention. FIG. 6 is an enlarged view of an area X of FIG. 5. Then, FIG. 7 is a diagram illustrating the process of mounting the engine 34. It is noted that an arrow F in FIG. 5 represents the advancing direction of the backhoe 100. Also, an arrow A illustrated FIG. 7 represents a mounting direction when the engine 34 is mounted. Further, a thin line Lw illustrated in FIG. 7 represents a welding line of a mount plate 42.

[0047]The engine supporting structure 4B is approximately similar to the engine supporting structure 4A according to the first embodiment of the present invention. Accordingly, the features that are different from those of the engine supporting structure 4A will be described bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com