Front sub-frame structure

一种前副车架、车身的技术,应用在下部结构、车辆部件、保险杠等方向,能够解决上下方向出现偏移等问题,达到提高支承刚性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

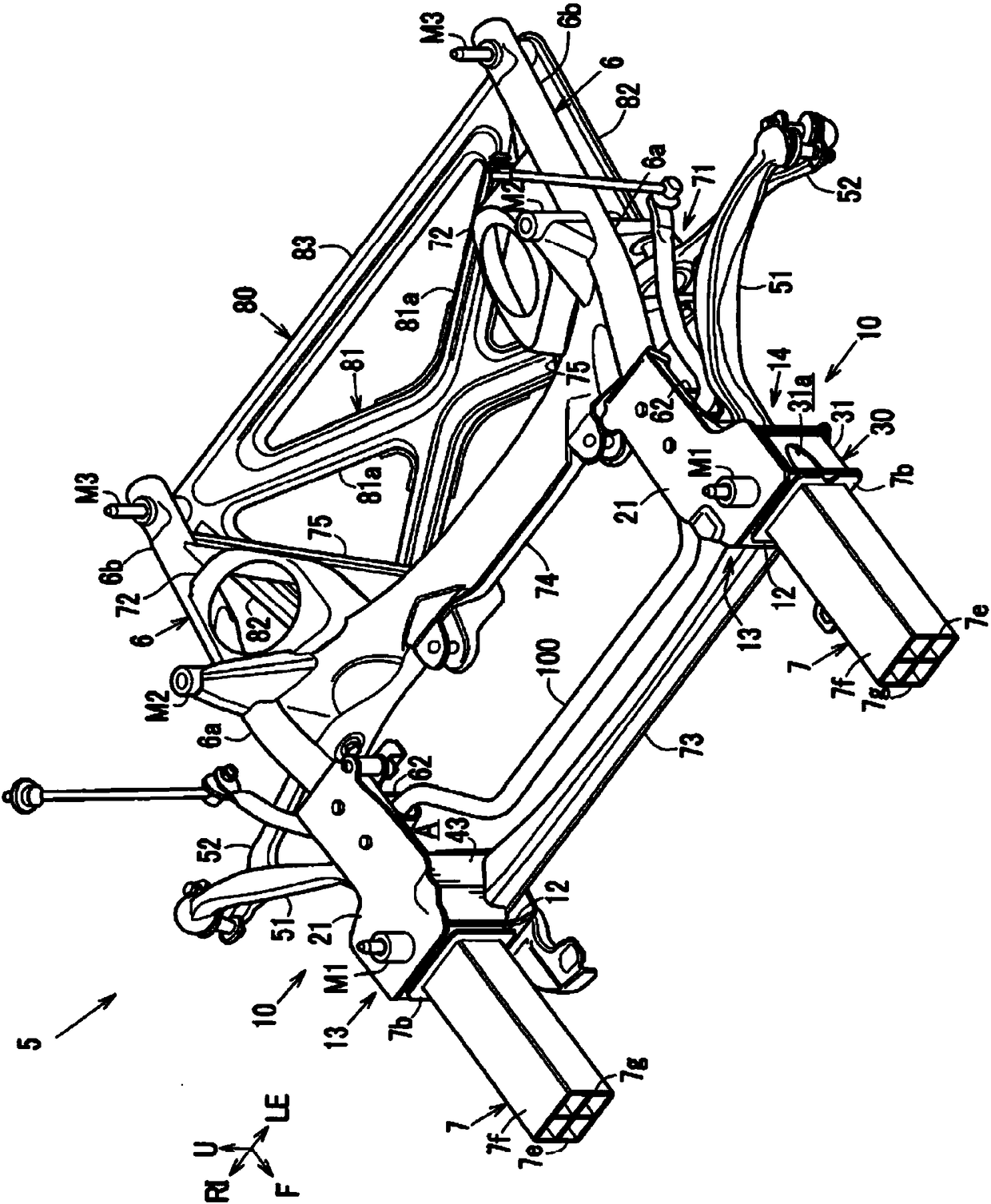

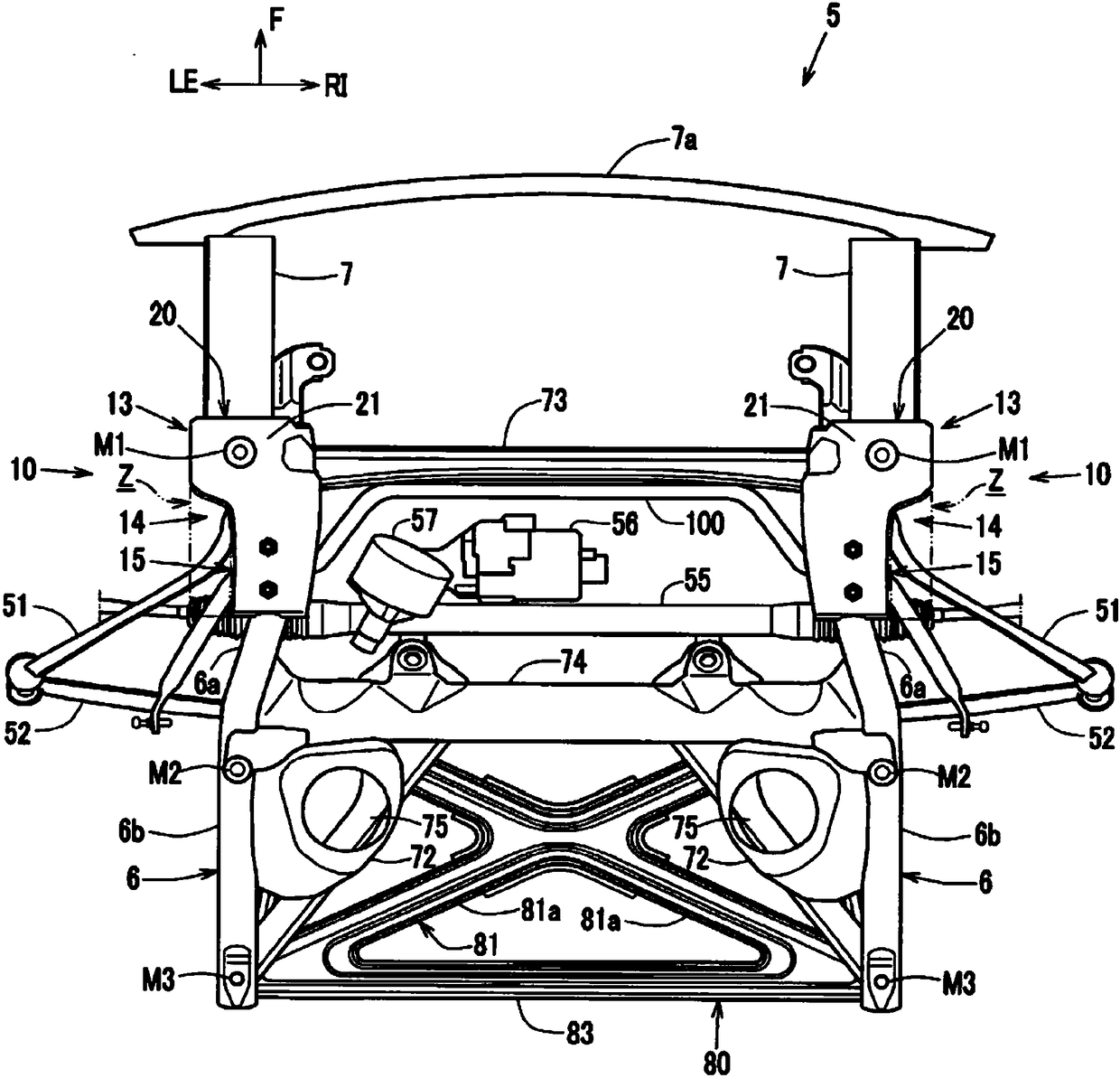

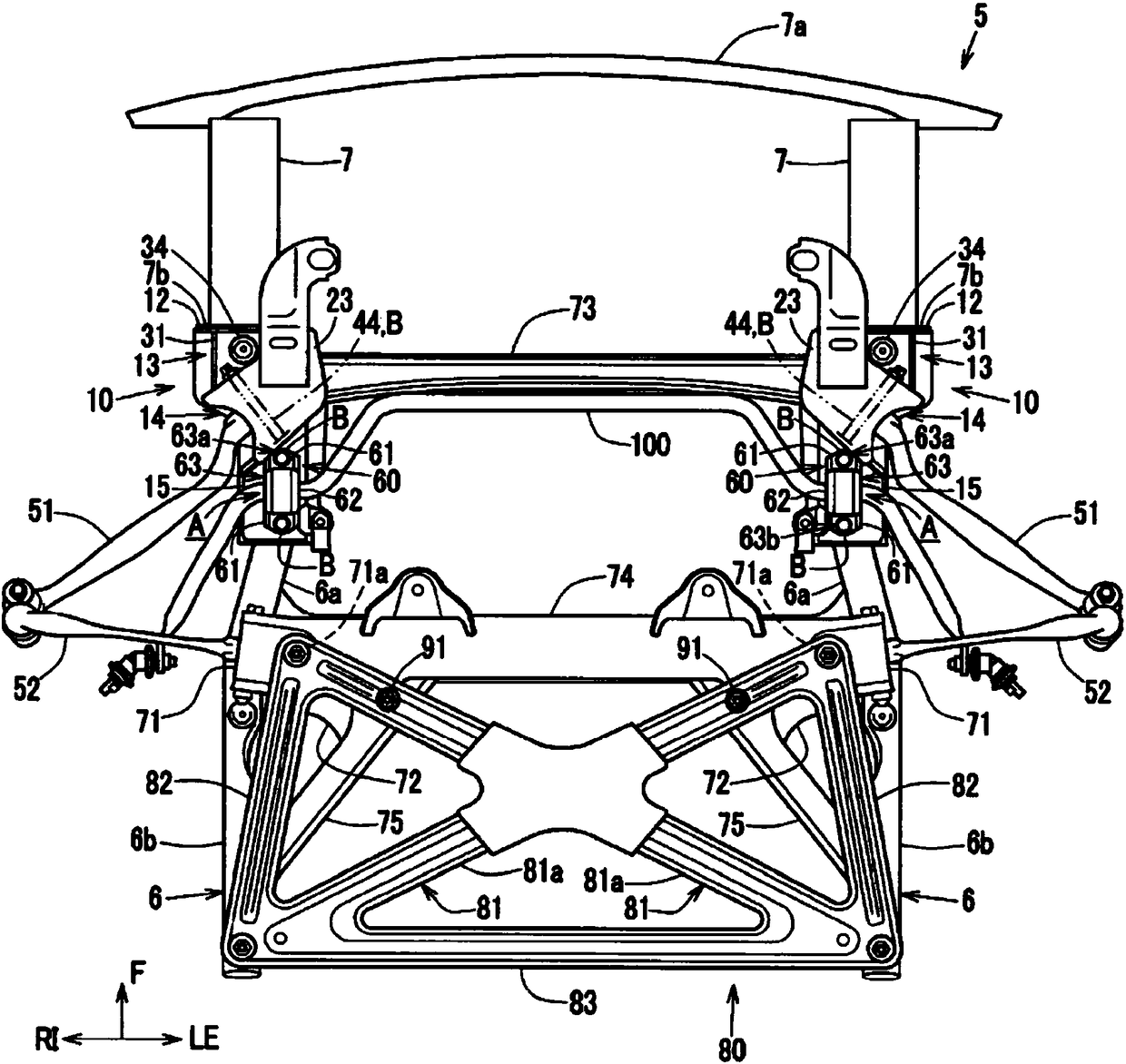

[0041] Hereinafter, embodiments will be described in detail with reference to the following drawings.

[0042] Figure 1 to Figure 7 The structure of the front subframe of the automobile of this embodiment is shown.

[0043] It should be noted that, in particular, figure 1 A perspective view showing the front subframe of the vehicle of this embodiment viewed from the front and obliquely above the left, Figure 7 An exploded perspective view showing a support frame seen from below and a front subframe with the support frame removed.

[0044] In the drawings of this embodiment, figure 2 In other figures, illustration of the steering rack 55, the power steering actuator (power steering motor) 56, and the power steering pinion 57 is omitted. Figure 4 The illustration of the pull rod 51 and the lower arm 52 is omitted, Figure 5 and Figure 6 The illustration of the sub-bumper reinforcement 7a is omitted, Figure 7 and later Figure 8 The above-mentioned sub-bumper reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com