Rear loading road milling machine with height adjustable sealing device

A technology of closing device and milling machine, applied in the direction of road, road, road repair, etc., can solve the problems of inability to move forward, the guard plate is stuck, hinder the advancement, etc., and achieve the effect of eliminating interruption or stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

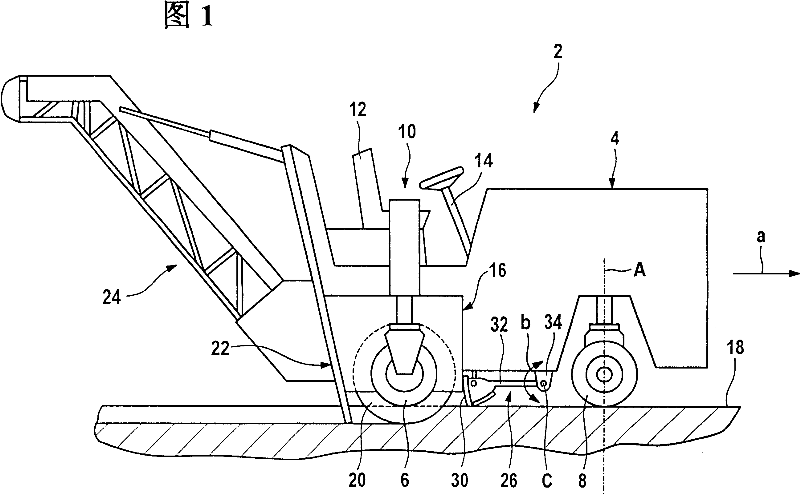

[0036]FIG. 1 shows a schematic view of an embodiment of a rear loading road milling machine 2 of the present invention. The road milling machine 2 has a frame 4, which in this embodiment is supported on three wheels 6, 6, 8, of which two rear wheels 6, 6 (only one of which can be seen in FIG. One wheel) is arranged on the side of the rear area, while the front wheel 8 is arranged in the middle of the road milling machine 2 front area. The rear wheels 6, 6 are adjusted in height by means of hydraulic pressure, and the turning of the milling machine 2 is realized by the front wheels 8, which can rotate around the vertical axis A. Furthermore, such a road milling machine 2 can be carried by a sprocket drive in the position of the wheels 6 , 6 , 8 . In addition, the number of wheels or sprocket drive described above can be varied.

[0037] Inside the frame 4 there is at least one drive for the milling rollers, the wheels 6, 6, 8 and the hydraulic system, as well as additional de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com