Door hinge with concealed bearing

A hinge device and hidden technology, applied in door/window fittings, wing parts, hinges, etc., can solve problems such as heavy rotation, high wear, and obstruction to door rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

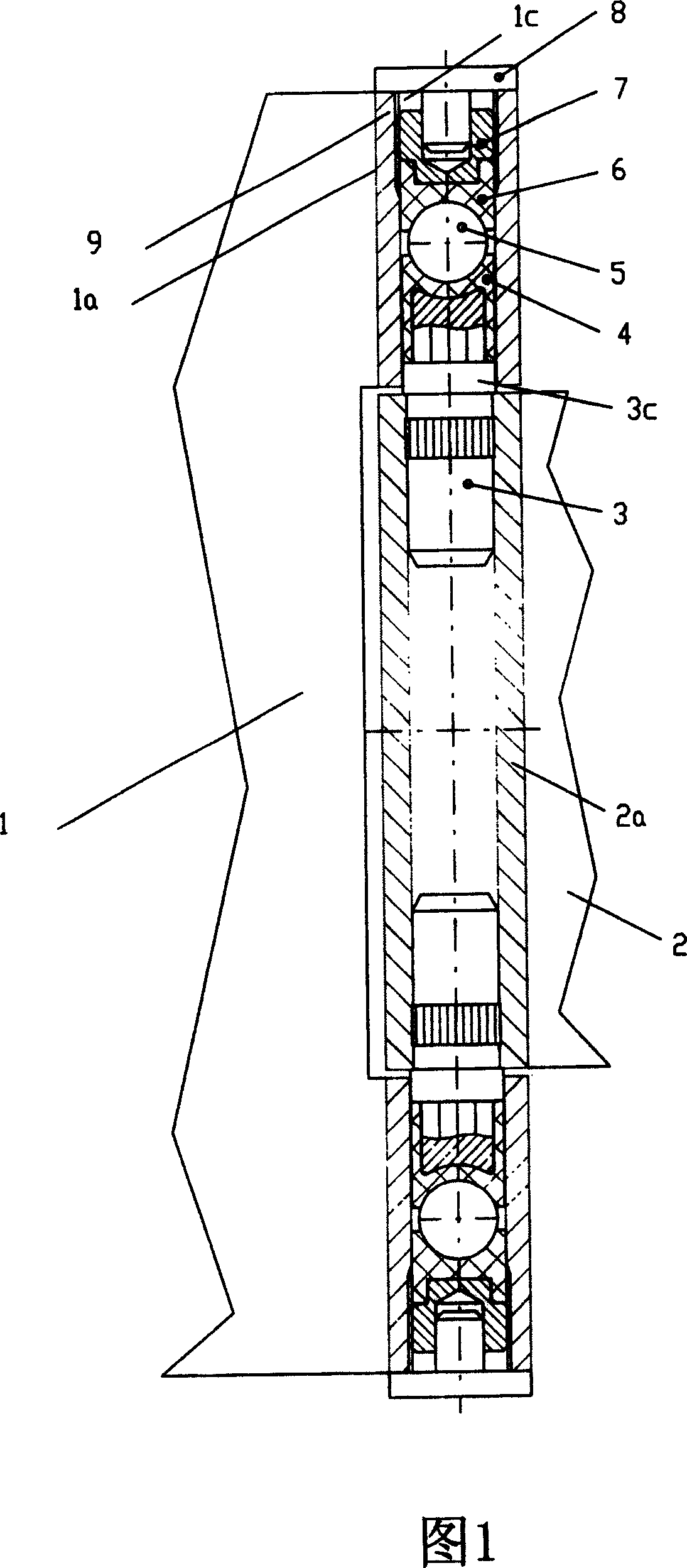

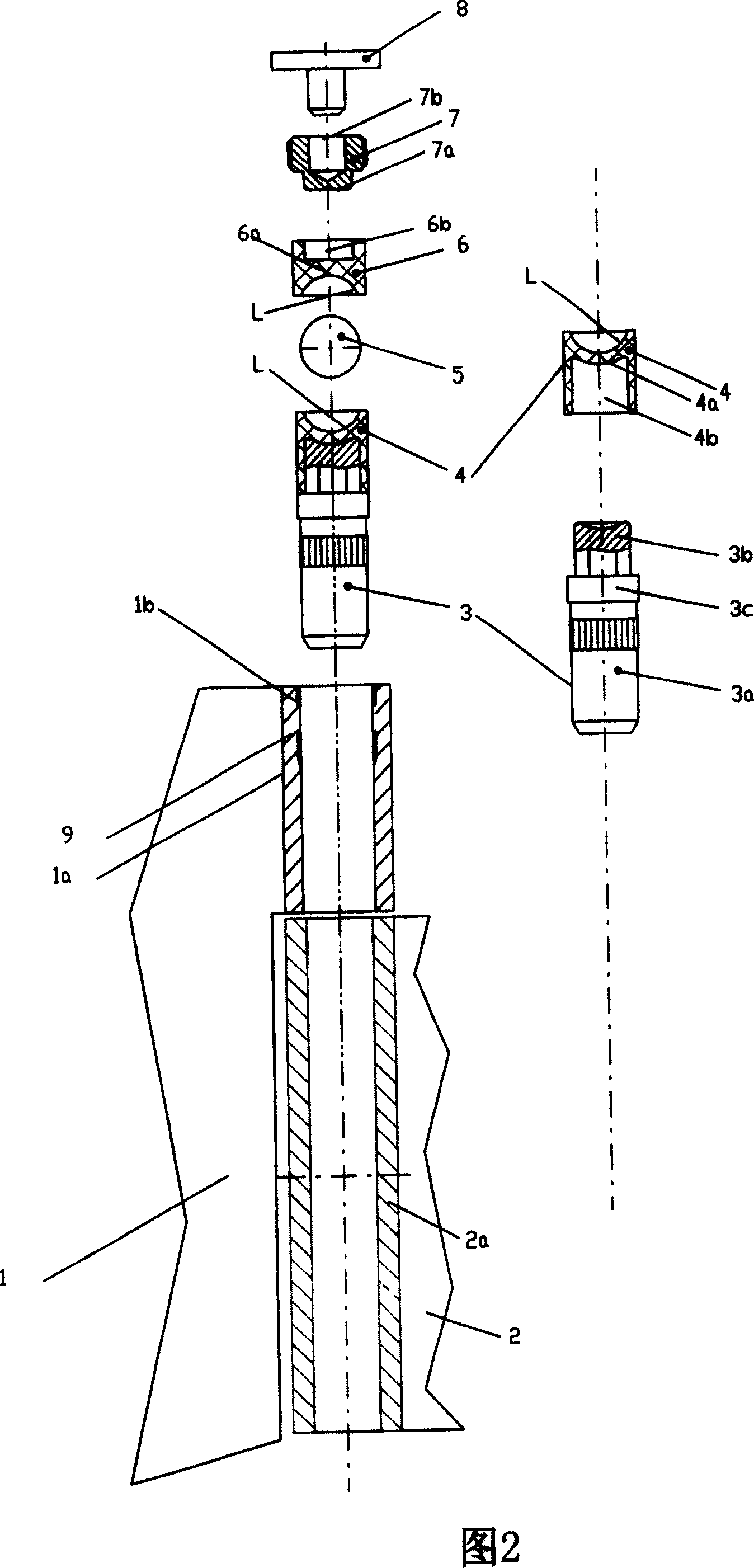

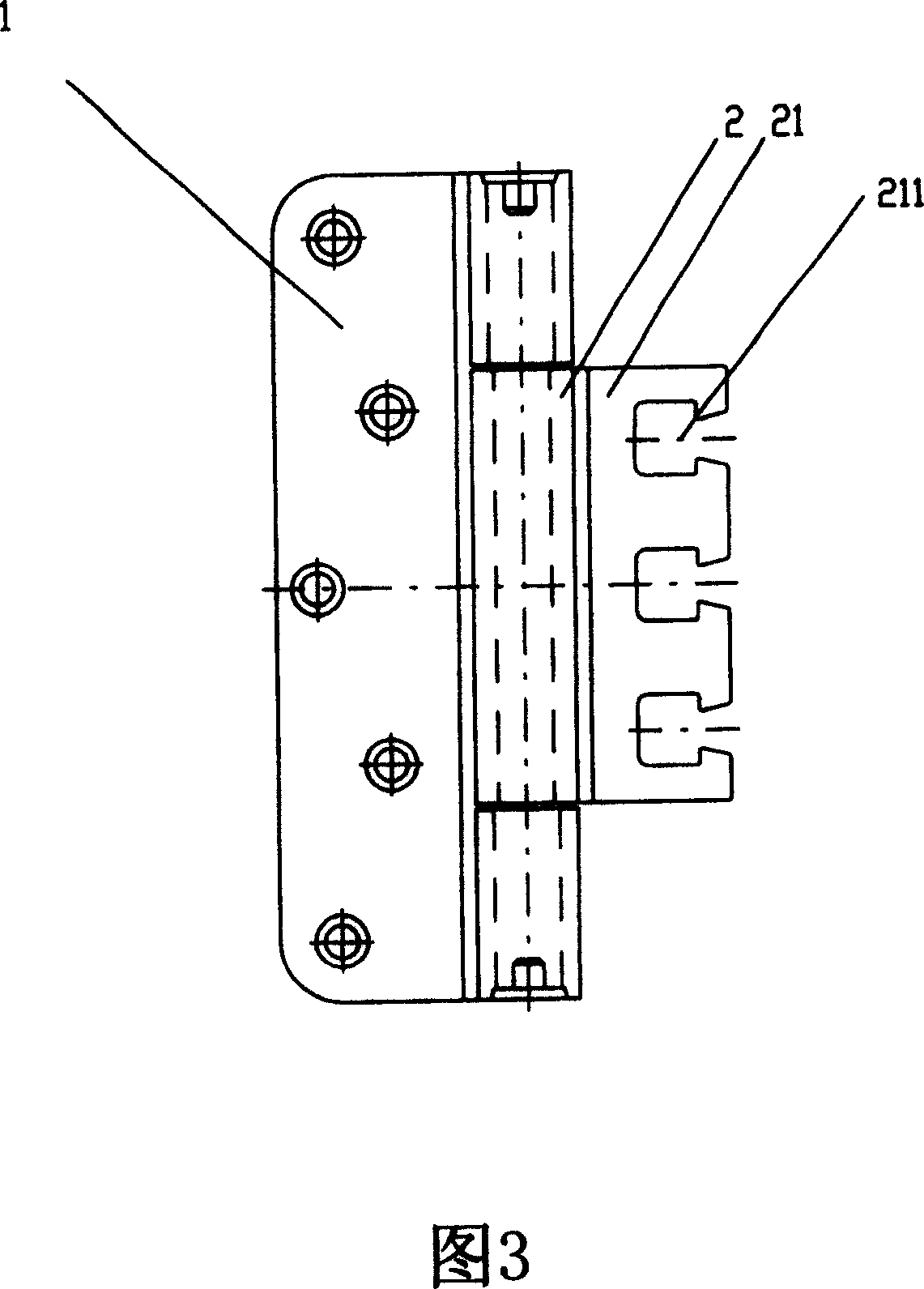

[0012] A door hinge device consisting of an inner and outer door hinge unit including additional means to allow it to be mounted to a door frame or door; the inner door hinge unit is mounted on the Between two or more cylindrical bearing parts on the external door hinge unit; inside the bearing parts there are first bearing sleeve and second bearing sleeve are set, the bearing sleeve is made of special engineering material plastic steel POM PTFE It is made; there is a ball between the first bearing sleeve and the second bearing sleeve, the ball is made of metal material, the door hinge device also includes a supporting bolt and an adjusting screw, and the first bearing sleeve is close to the inner The direction of the door hinge unit is firmly sleeved on the free end of the support bolt; the adjustment screw can be screwed into the bearing part; the second bearing sleeve is subjected to the counter pressure of the ball, away from the first bearing sleeve.

[0013] The door hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com