Substrate carrying device

A technology for conveying devices and substrates, which is applied to conveyor objects, transportation and packaging, furnaces, etc., and can solve problems such as cracking devices, uneven stress on glass substrates, and difficulty in maintaining long-term operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The substrate transfer device of the present invention will be explained in detail below with reference to various embodiments and accompanying drawings.

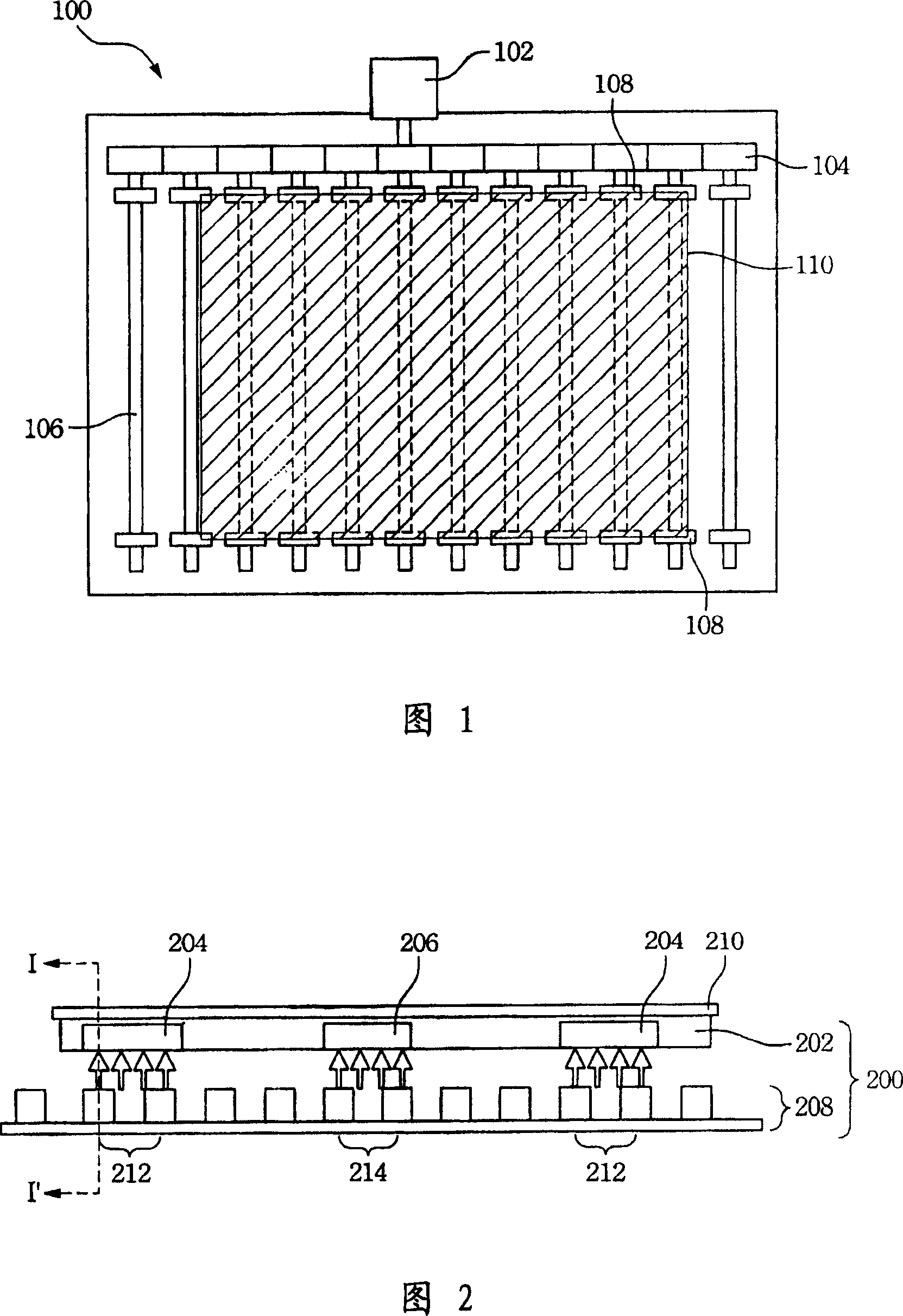

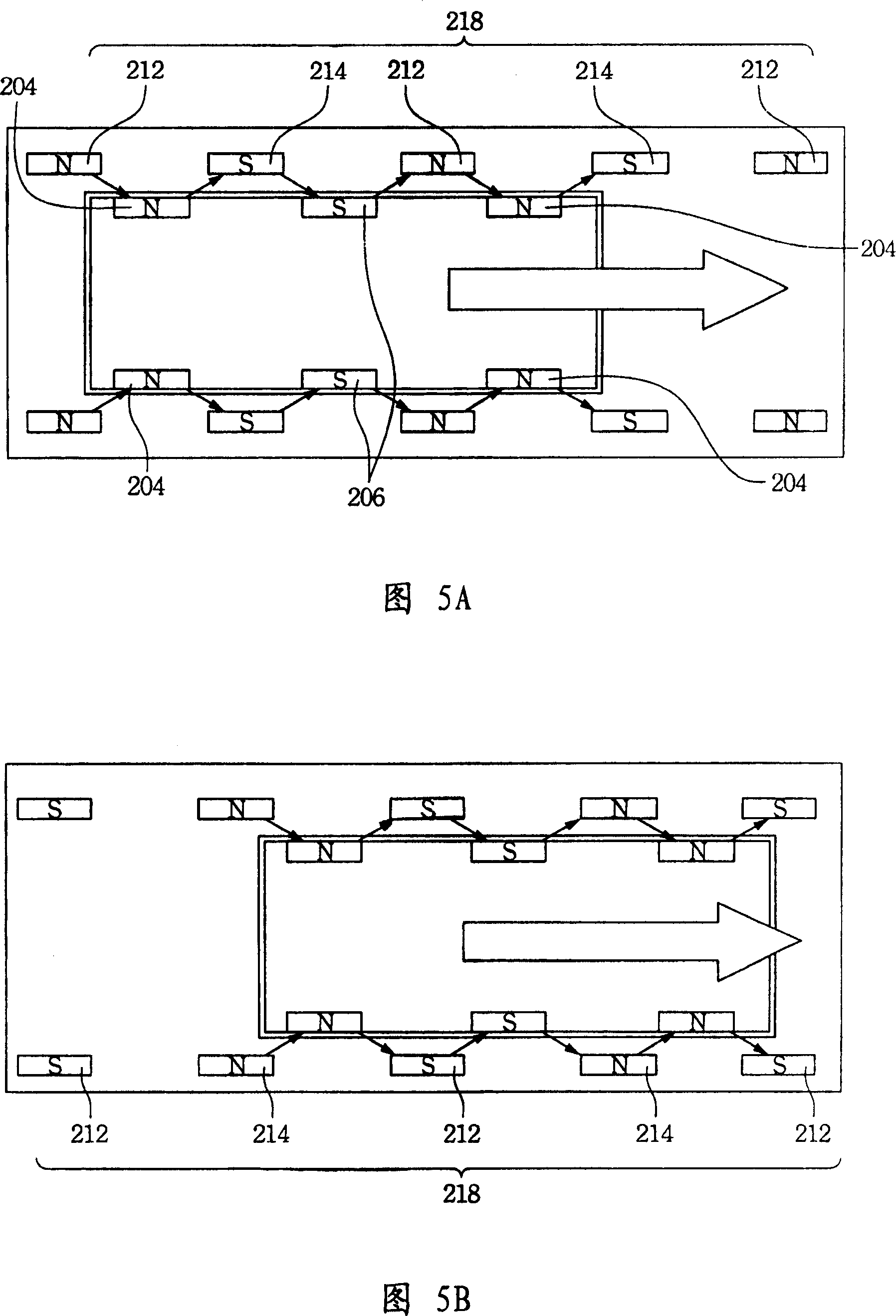

[0032] Please refer to FIG. 2 , which shows a side view of a glass substrate conveying device according to a preferred embodiment of the present invention. The glass substrate conveying device 200 includes a carrying platform 202 and a conveying track 208 , and a glass substrate 210 is placed on the carrying platform 202 . The carrying platform 202 has magnetic blocks 204 , 206 with different fixed magnetic properties alternately disposed under the carrying platform 202 . In this embodiment, the magnetic block 204 is N-pole magnetic, and the magnetic block 206 is S-polar magnetic; of course, vice versa is also possible.

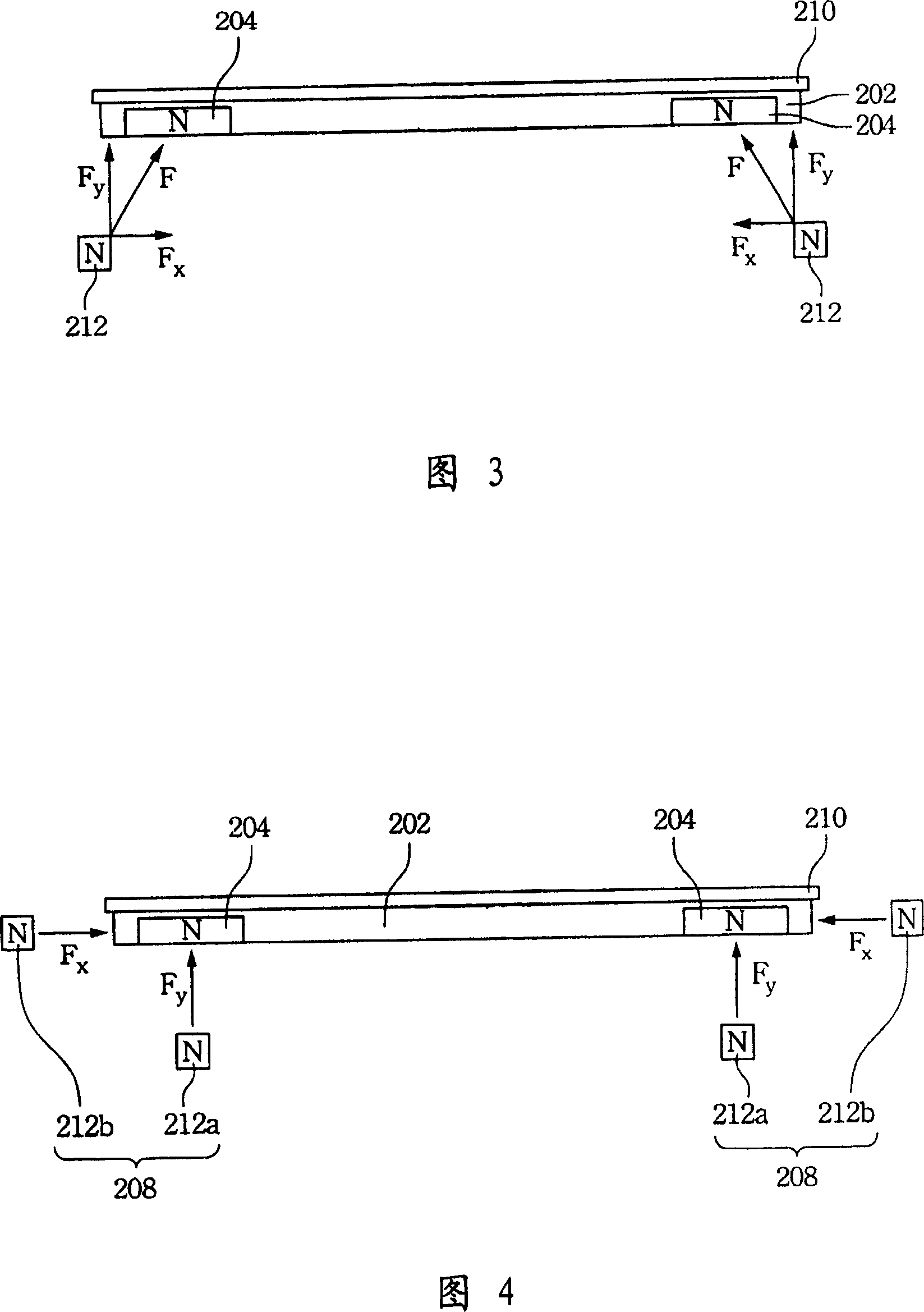

[0033] The conveying track 208 is magnetic blocks 212 , 214 with variable magnetic properties, wherein the magnetic blocks 212 , 214 may have different magnetic properties. Please refer to Fig. 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com