Vortex type compressor

A technology of scroll compressors and compression chambers, applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve the problems of reducing compressor efficiency, increasing sliding loss, increasing leakage loss, etc., to achieve The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

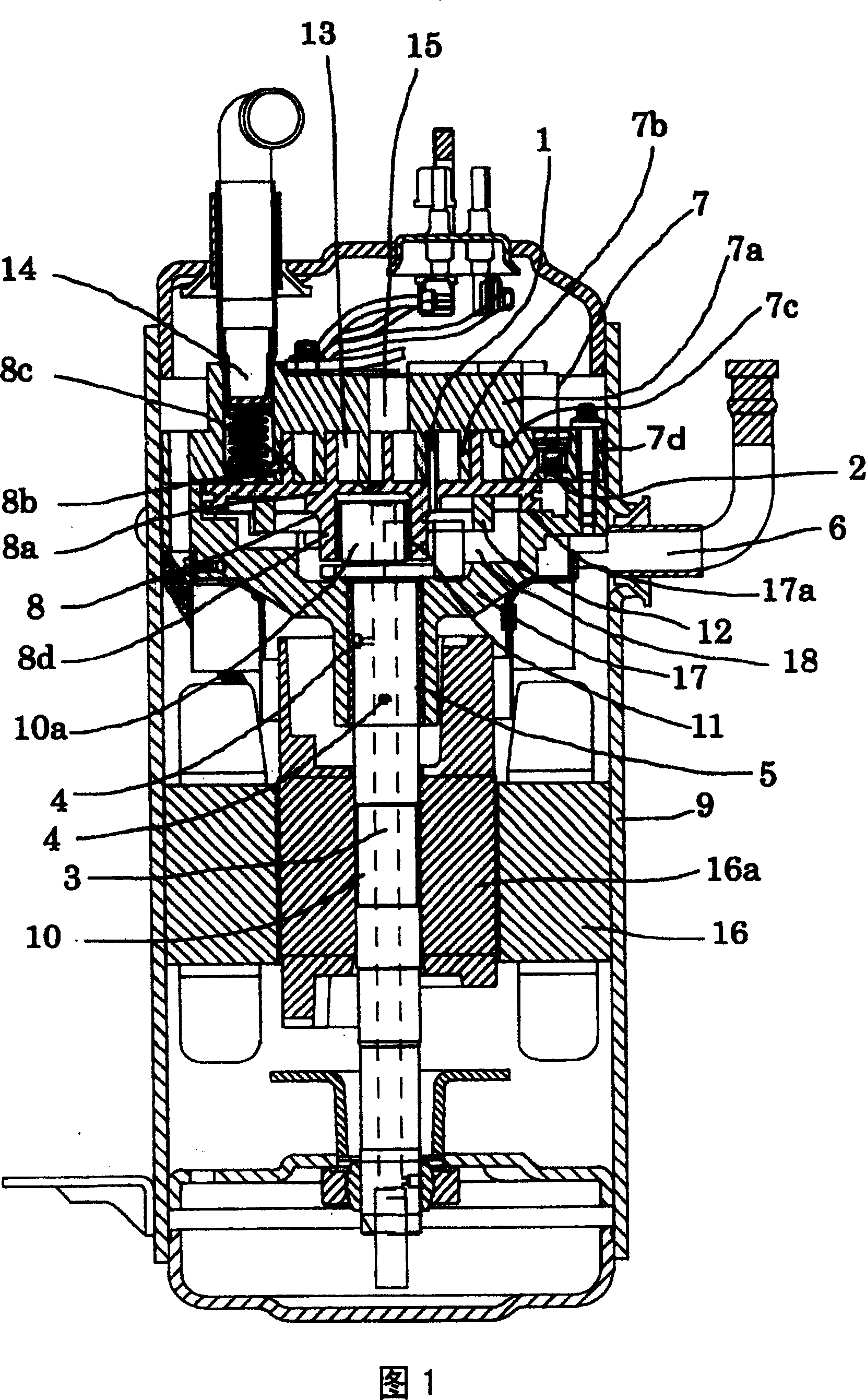

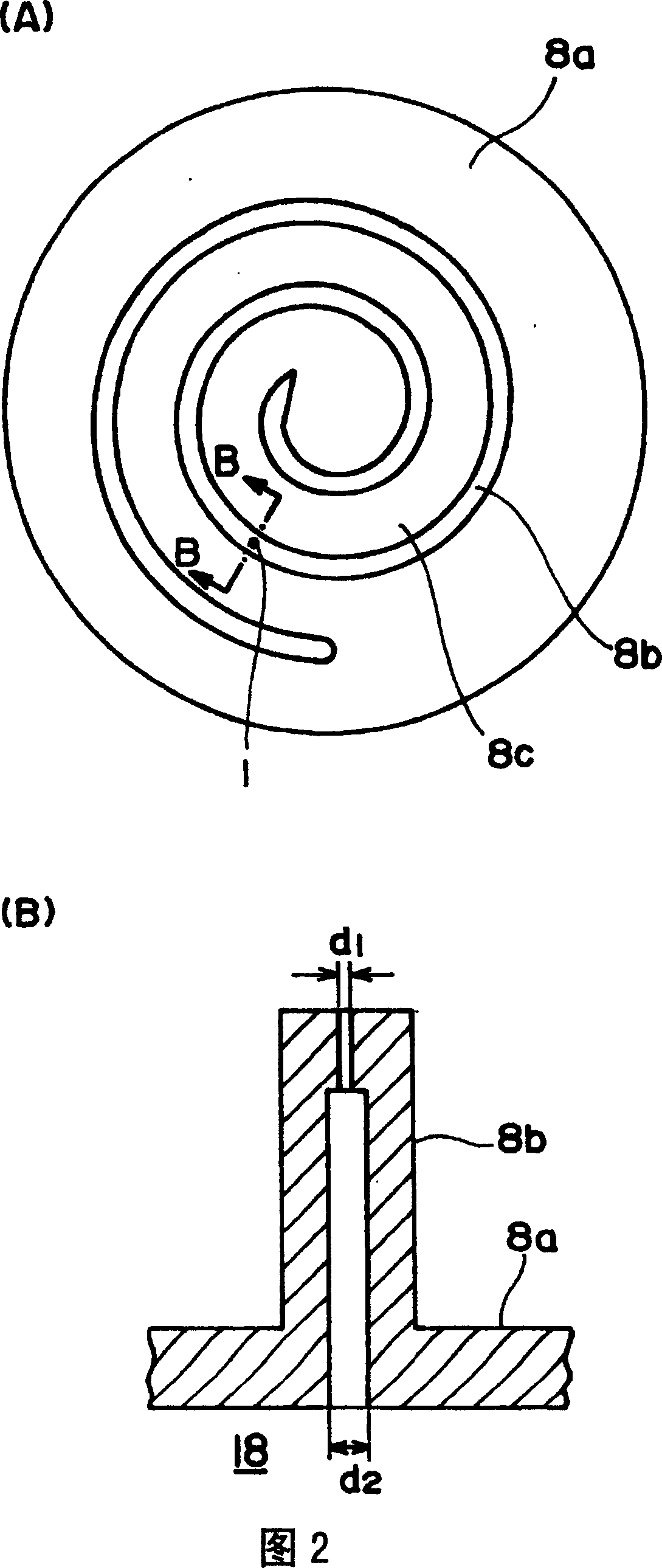

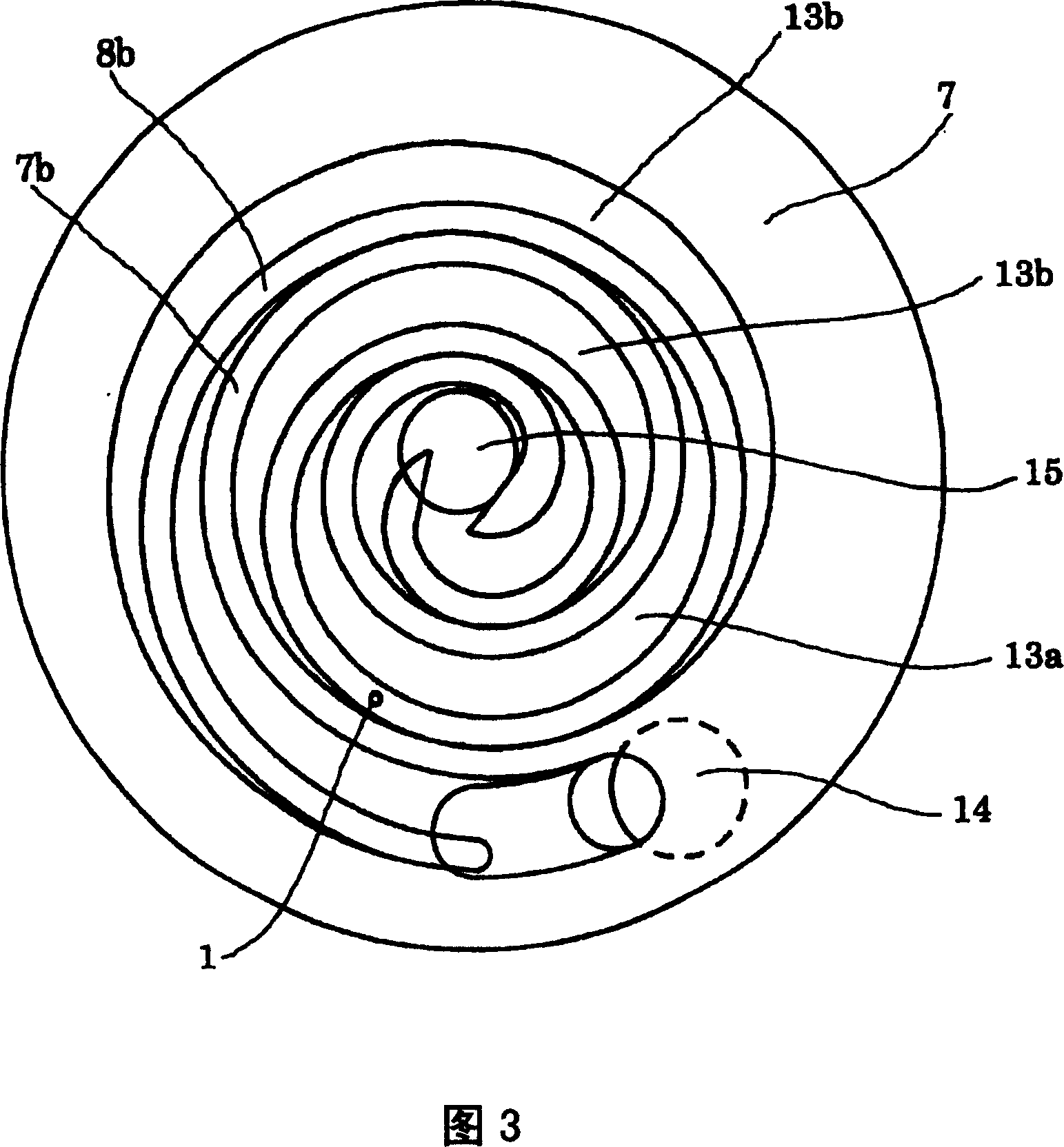

[0021] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. Fig. 1 is an overall longitudinal sectional view of a scroll compressor according to an embodiment of the present invention. Fig. 2(A) is a plan view of the movable scroll seen from the lap side of the characteristic part of this embodiment, and (B) is a B-B cross-sectional view of Fig. 1(A).

[0022] As shown in FIG. 1 , the fixed scroll 7 is composed of a disk-shaped end plate 7 a, a spiral coil 7 b erected on the end plate 7 a, and a spiral coil 7 b positioned on the outer peripheral side of the end plate 7 a and formed to surround the coil. 7b is constituted by a cylindrical support portion 7d. The surface of the end plate 7a on which the coil plate 7b is erected is the tooth bottom 7c. In addition, the fixed scroll 7 is fixed to the frame 17 with bolts or the like at the support portion 7d, and the frame 17 integrated with the fixed scroll 7 is fixed to the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com