Corrosion resistance magnet and producing method thereof

A corrosion-resistant and magnet technology, applied in the field of corrosion-resistant magnets, can solve the problem of easy corrosion of magnets, and achieve the effects of high bonding strength, not easy to peel off, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

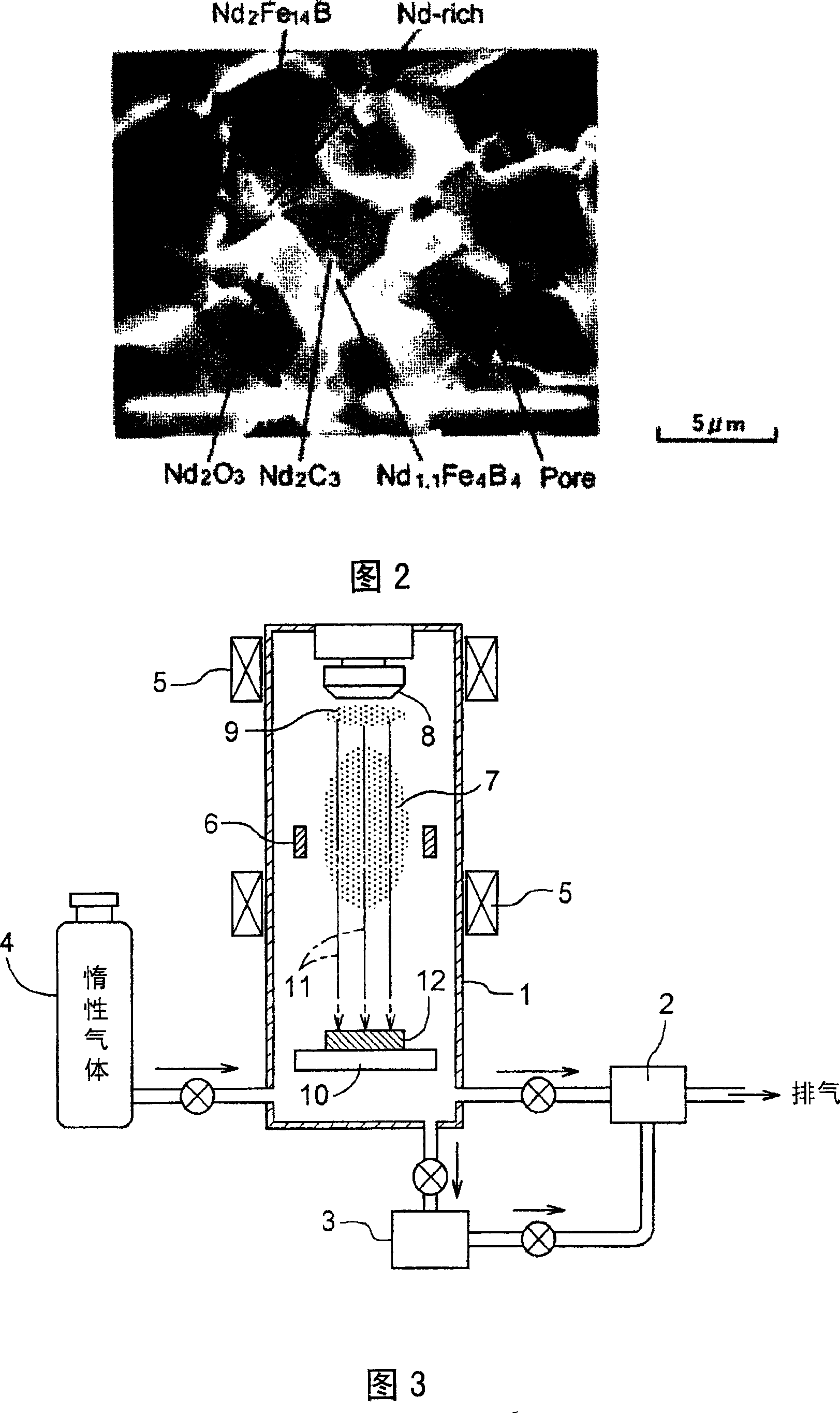

[0050] In the corrosion-resistant magnet of the present invention, the surface of the rare earth magnet has an inactive phase including at least one element constituting the aforementioned rare earth magnet. In this way, the surface of the rare-earth magnet can be deactivated, and corrosion of the rare-earth magnet can be prevented. In addition, since the inactive phase contains at least one element among the elements constituting the above-mentioned rare earth magnet, it is easy to bond with the surface of the magnet, the bond strength is high, and the coating film is not easily peeled off.

[0051] Also, rare earth magnets are generally Re-B-Fe series or Re-Tm-B series (Re is an element selected from rare earth metals, and Tm is an element selected from transition metals. ), is composed of Re, B, Fe, etc. or Re, Tm, B, etc. various elements. In this way, the inactive phase may contain at least one element among the elements constituting the rare earth magnet.

[0052] In a...

Embodiment 1

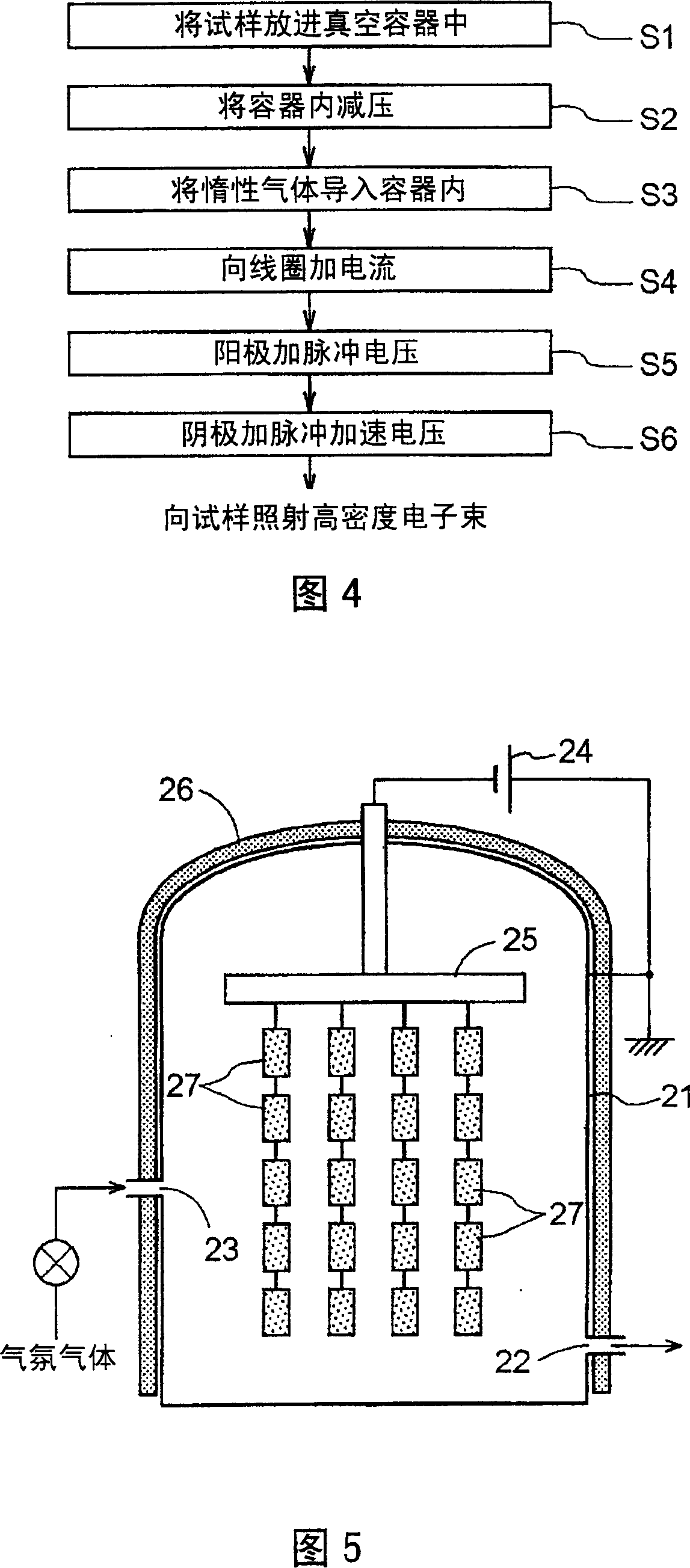

[0094] In Examples 1 and 2, electron beams were irradiated with the temperature raised to about 1400° C. from the surface of the magnet to a thickness of 10 μm. In Example 1, electron beams were irradiated only once, and in Example 2, electron beams were irradiated continuously before and after electron beam irradiation under the same conditions as in Example 1 in order to relax the thermal stress on the magnet surface.

Embodiment 3

[0095] In Examples 3-5, electron beams were irradiated with the temperature raised to about 3000° C. from the surface of the magnet to a thickness of 10 μm. In Example 3, the electron beam was irradiated only once. Thus, during electron beam irradiation, the temperature rises sharply to about 3000°C within a short delay time determined by the heat capacity and thermal conductivity of the magnet, and the magnet is cooled down to a temperature close to the temperature in the container within a short delay time. temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com