Equipment used for space position precise measurement

A technology for precise measurement and spatial position, which is applied in the application field of laser photoelectric measurement technology to achieve the effect of solving real-time measurement and achieving high-precision measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

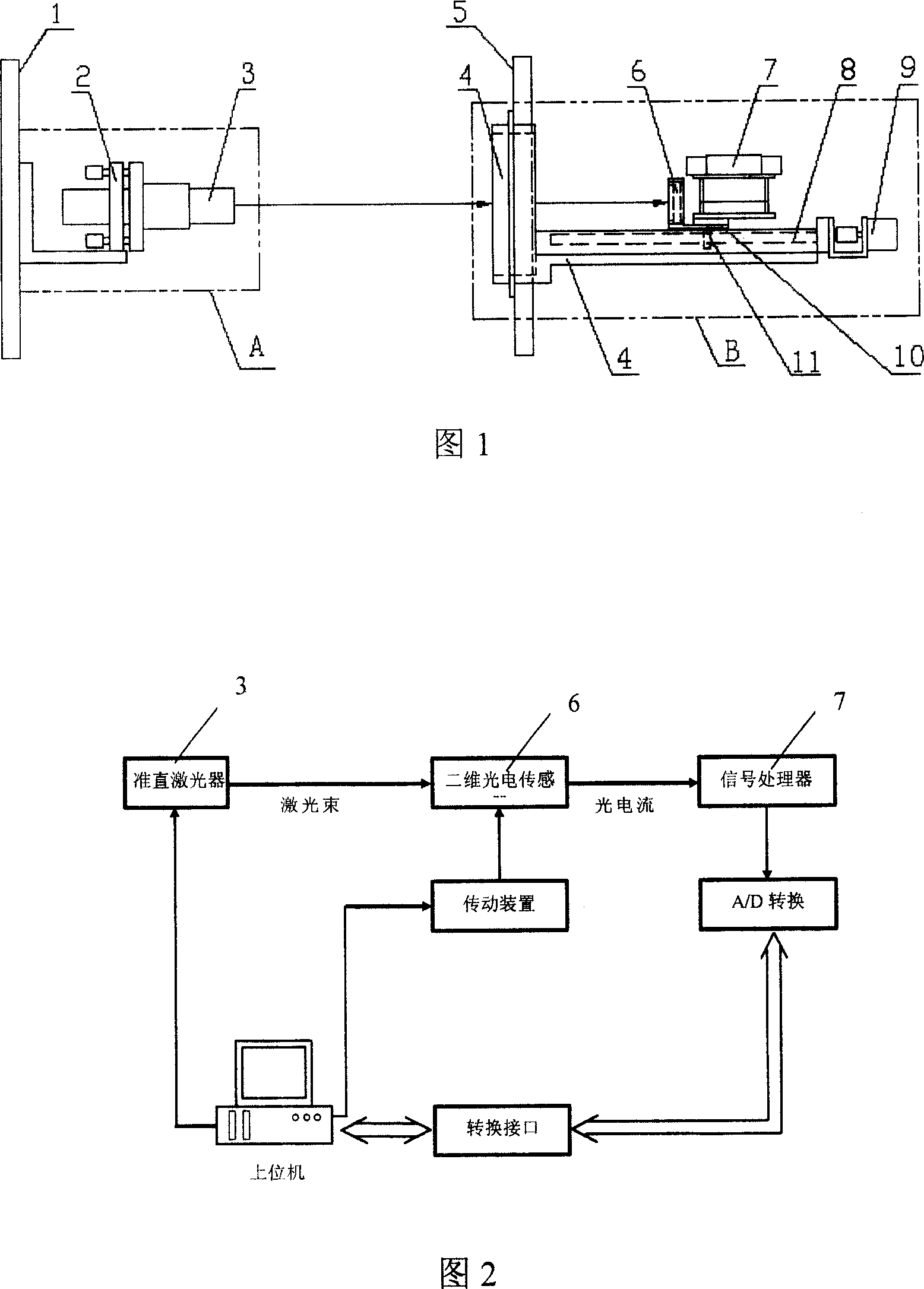

[0012] Referring to Fig. 1, the present invention comprises emission reference plate 1, collimating laser 3, beam adjuster 2, receiving reference plate 5, support frame 4, adopts two-dimensional photoelectric sensor 6 and signal processor 7 of two-dimensional PSD or two-dimensional CCD . The collimated laser 3 is connected with the beam adjuster 2, and the beam adjuster 2 is installed on the emission reference plate 1 to make the laser beam coincide with the normal line of the emission reference plate 1 to form a laser emitting device A. The receiving reference plate 5 is fixed to the side end of the support frame 4, and the transmission device is installed on the support frame 4. A two-dimensional photoelectric sensor 6 and a signal processor 7 are installed on the transmission device, and the moving track of the coordinate center of the detection surface of the two-dimensional photoelectric sensor 6 is consistent with the normal line of the receiving reference plate 5 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com