Organic luminescent display and manufacturing method thereof

A technology of light-emitting display and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electroluminescence light source, light source, etc., and can solve problems such as difficulty in controlling the optimal width of the gap, breaking of the sealant layer, and too wide a gap reserved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

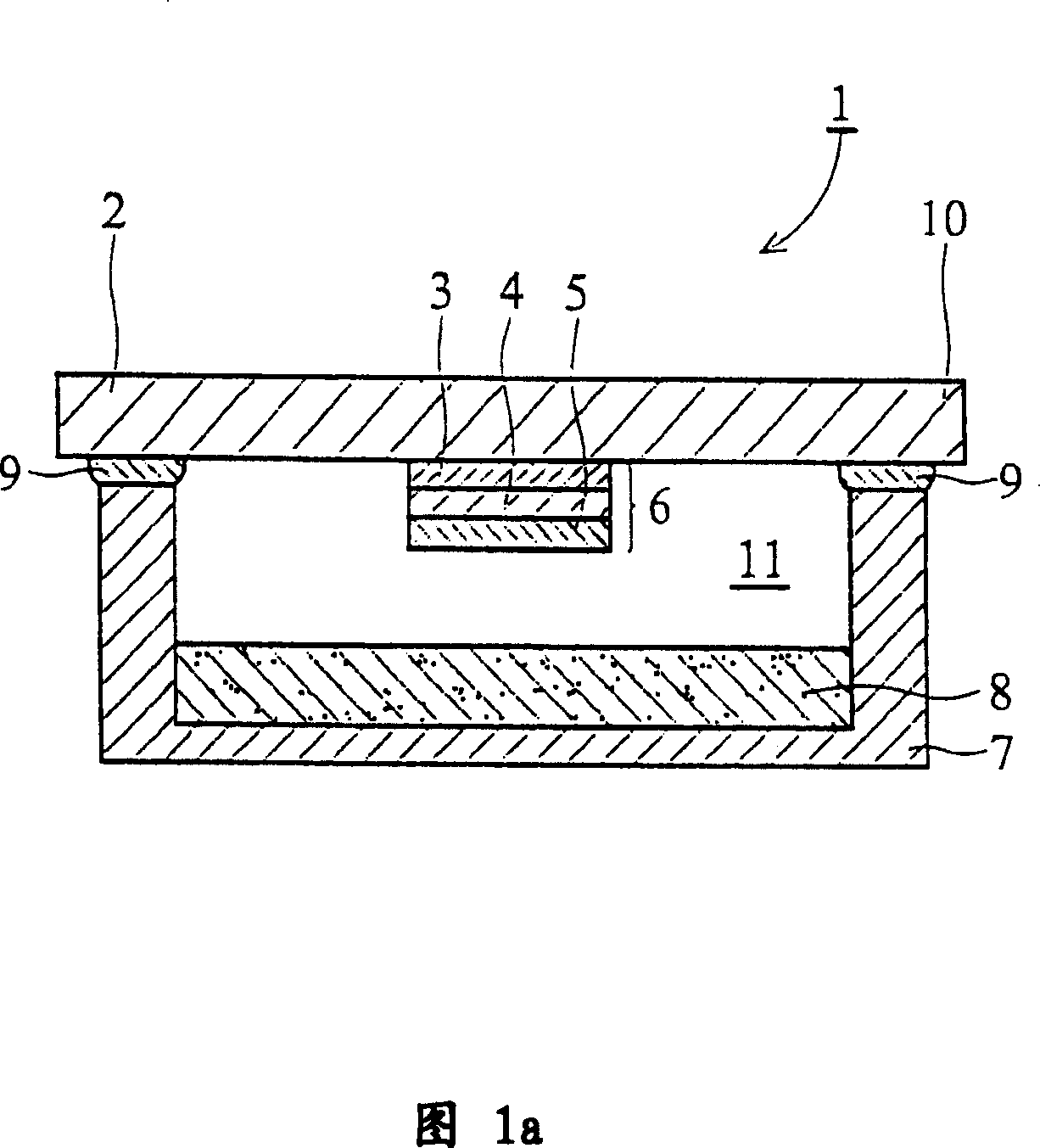

[0045] Please refer to FIG. 2 , illustrating an embodiment of the present invention, the fabrication of an organic light emitting display. First, as shown in FIG. 2 , a substrate 22 is provided. The substrate 22 is a light-transmitting glass, polymer, ceramic or plastic substrate, wherein the plastic substrate is made of polyethylene terephthalate (polyethyleneterephthalate), polyester (polyester), polycarbonate (polycarbonates), polyacetamide ( polyimide), Arton, polyacrylates (polyacrylates) or polystyrene (polystyrene) materials.

[0046] Next, a first electrode 25 is formed on the substrate 22 . The first electrode 25 is, for example, a transparent electrode, or an anode conductive layer, and the transparent electrode is indium tin oxide (ITO), indium zinc oxide (IZO), zinc aluminum oxide (AZO) or zinc oxide (ZnO ).

[0047] Continuing to form an organic light-emitting structure layer on the first electrode 25, the organic light-emitting structure layer sequentially inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap