Cuttings recovering apparatus for electrode trimmer

A recovery device and electrode head technology, applied in the direction of electrode characteristics, resistance welding equipment, maintenance and safety accessories, etc., can solve the problems of difficult chip recovery and large-scale equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

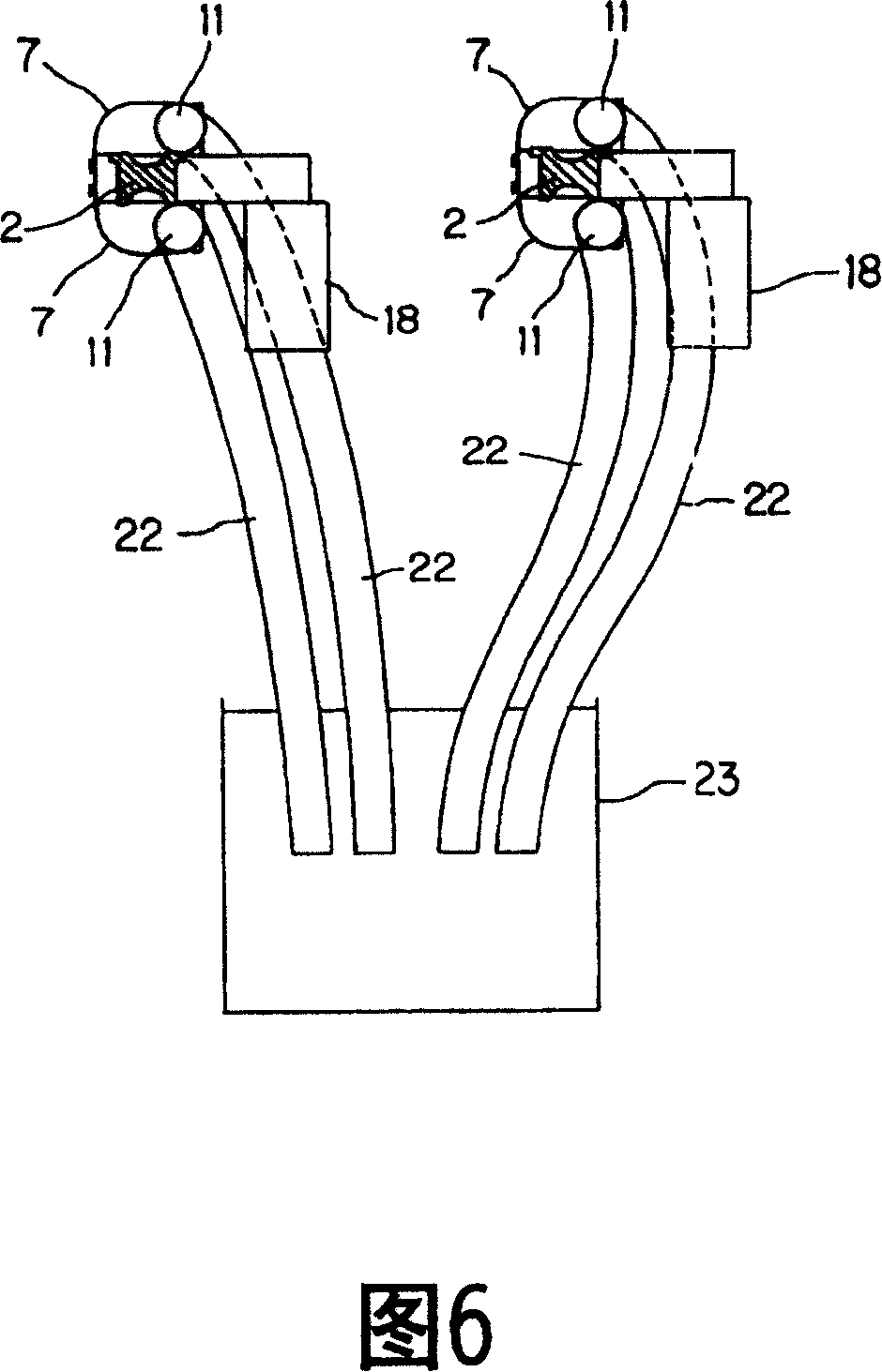

[0015] Embodiments of the present invention will be described with reference to the drawings.

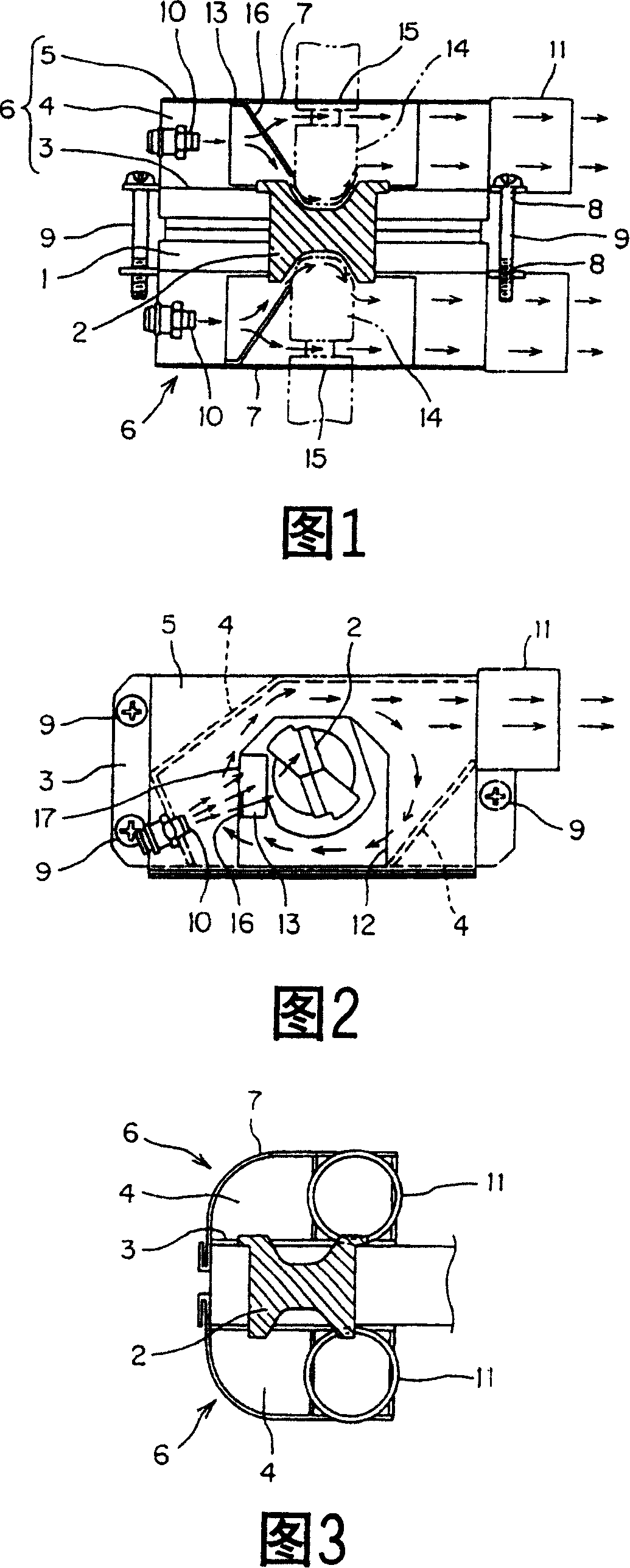

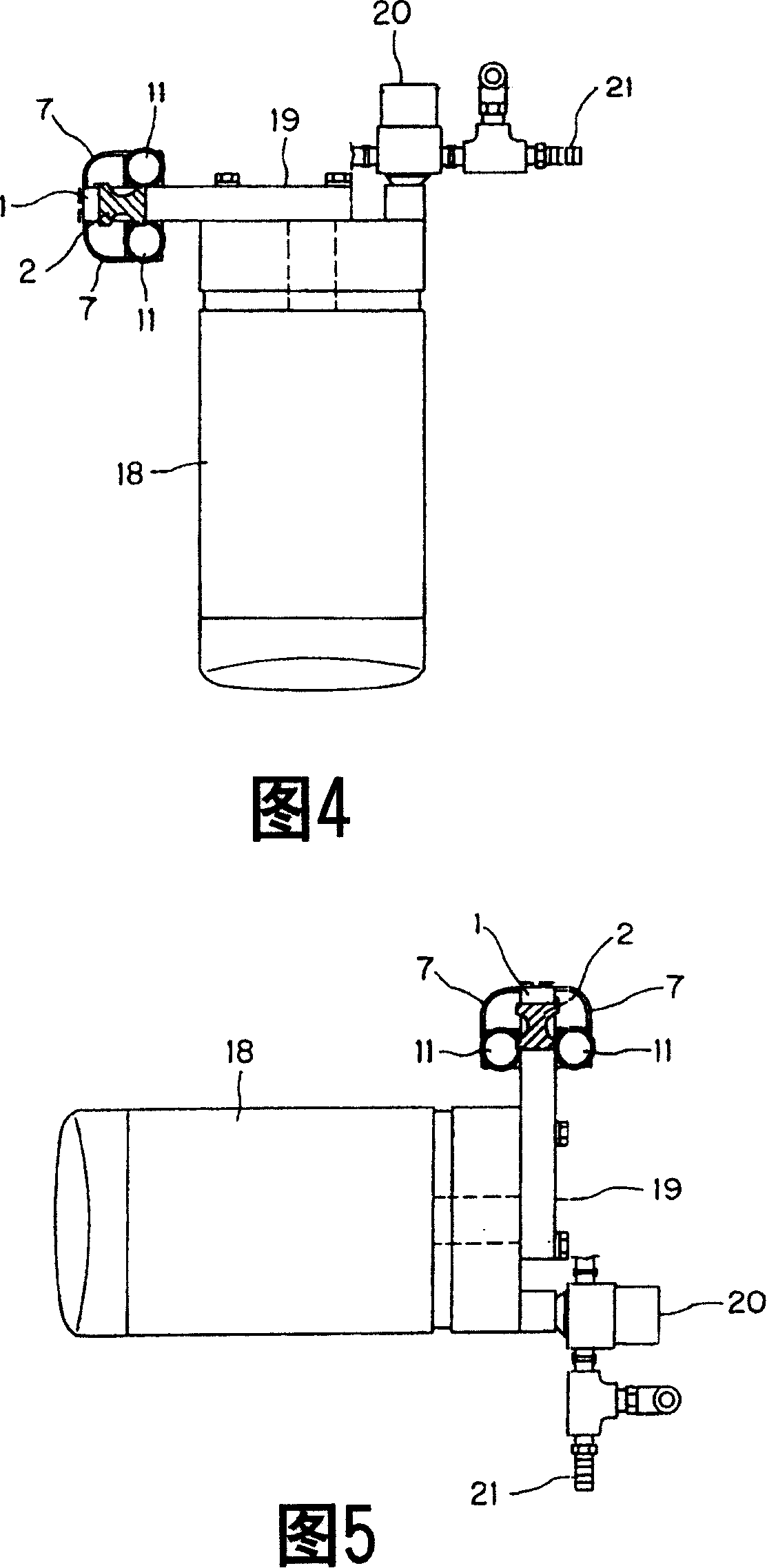

[0016] FIG. 1 is a front explanatory view of main parts of a tip dresser according to the present invention, FIG. 2 is a plan view thereof, and FIG. 3 is a side view thereof.

[0017] In the figure, 1 is a disc-shaped cutter frame, which holds a cutter 2 on the cutter frame 1, and a housing composed of a base plate 3, a side plate 4 and a partially opened cover plate 5 is arranged on both sides of the cutter 2 respectively. 6, 6. The opening surface of the casing 6 is covered by a cover 7 .

[0018] Screw holes 8, 8 .

[0019] On the side plate 4 of the housing 6, a nozzle 10 for blowing compressed air is arranged, and a chip discharge port 11 is formed at a position opposite to the position where the nozzle 10 is arranged. In addition, the discharge port 11 may be arranged at an appropriate position in the casing 6 .

[0020] An opening 12 is formed in a part of the cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com