Special new pattern identification sign for testing film layer thickness in semiconductor device

A pattern recognition and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, semiconductor/solid-state device testing/measurement, etc., can solve the problem of prolonging the process cycle, interrupting the process, and not being able to correctly test the film thickness of semiconductor devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

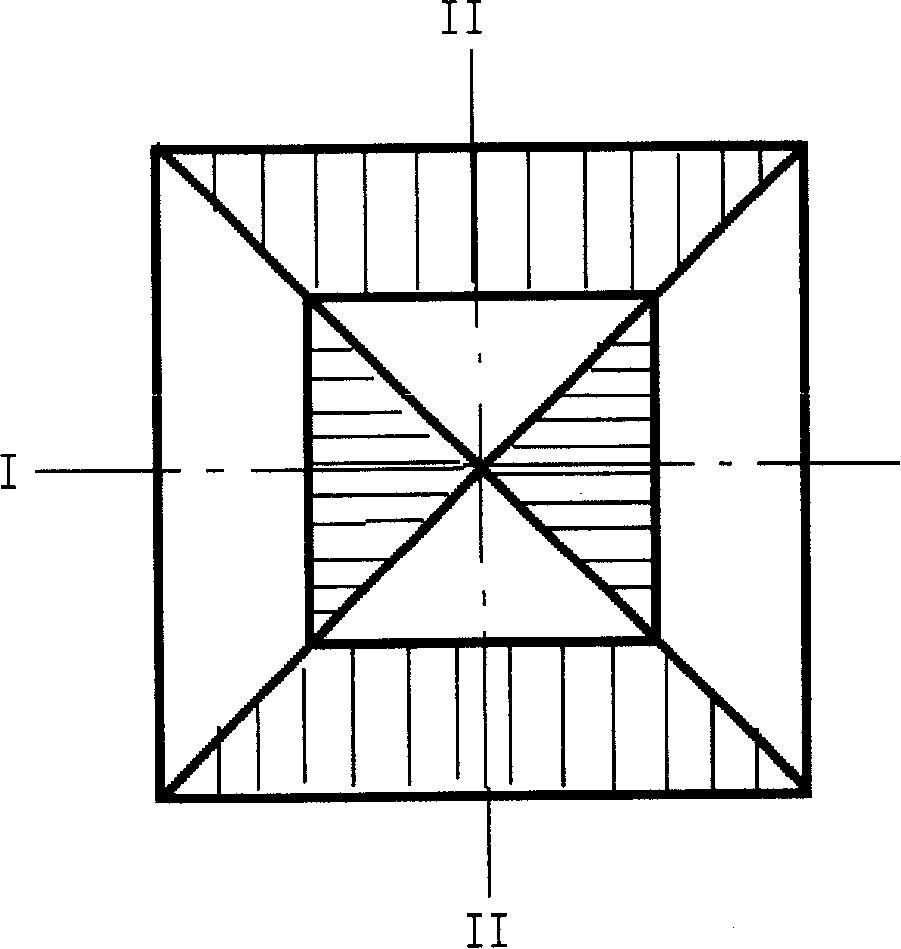

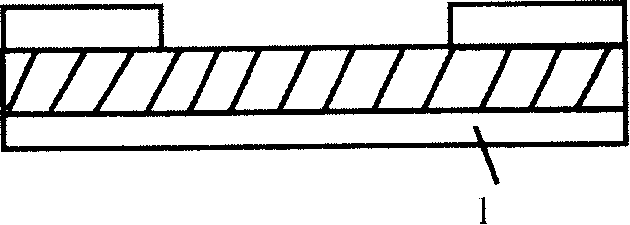

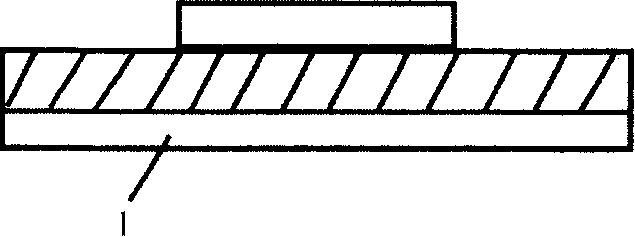

[0029] figure 1 It is a top view of a new graphic identification mark dedicated to film thickness in a semiconductor device for testing according to the first embodiment of the present invention. figure 2 yes press figure 1 A cross-sectional view of line I-I showing a new graphic identification mark dedicated to film layer thickness in the test semiconductor device according to the first embodiment of the present invention. image 3 yes press figure 1 It is a sectional view showing the II-II line of the new graphic identification mark dedicated to film layer thickness in the test semiconductor device according to the first embodiment of the present invention.

[0030] According to the first embodiment of the present invention, the special new graphic identification mark for testing the thickness of the film layer in the semiconductor device is arranged on the wafer. The outline of the new graphic identification mark is that two squares with different areas are overlapped ac...

no. 2 example

[0033] Figure 4 is a top view of a new graphic identification mark dedicated to film thickness in a semiconductor device for testing according to a second embodiment of the present invention. Figure 5 yes press Figure 4 A cross-sectional view showing the I-I line of the new graphic identification mark dedicated to the film layer thickness in the test semiconductor device according to the second embodiment of the present invention. Figure 6 yes press Figure 4A cross-sectional view showing the II-II line of the new graphic identification mark dedicated to the film layer thickness in the test semiconductor device according to the second embodiment of the present invention.

[0034] According to the second embodiment of the present invention, the special new graphic identification mark for testing the thickness of the film layer in the semiconductor device is arranged on the wafer. The outline of the new graphic identification mark is that two rectangles with different area...

no. 3 example

[0037] Figure 7 is an item view of a new graphic identification mark dedicated to film layer thickness in testing a semiconductor device according to the first embodiment of the present invention. Figure 8 yes press Figure 7 A cross-sectional view of line I-I showing a new graphic identification mark dedicated to film thickness in a semiconductor device for testing according to the third embodiment of the present invention. Figure 9 yes press Figure 7 A cross-sectional view along line II-II of a new graphic identification mark dedicated to film layer thickness in a semiconductor device for testing according to the third embodiment of the present invention.

[0038] According to the third embodiment of the present invention, the special new graphic identification mark for testing the thickness of the film layer in the semiconductor device is arranged on the wafer. The outline of the new graphic identification mark is that two hexagons with different areas are overlapped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com