Potato harvester

A harvester and potato technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of large drop between the screen surface and the bar conveyor chain, unreasonable force, inconvenient use and maintenance, etc. The effect of full performance, stable operation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

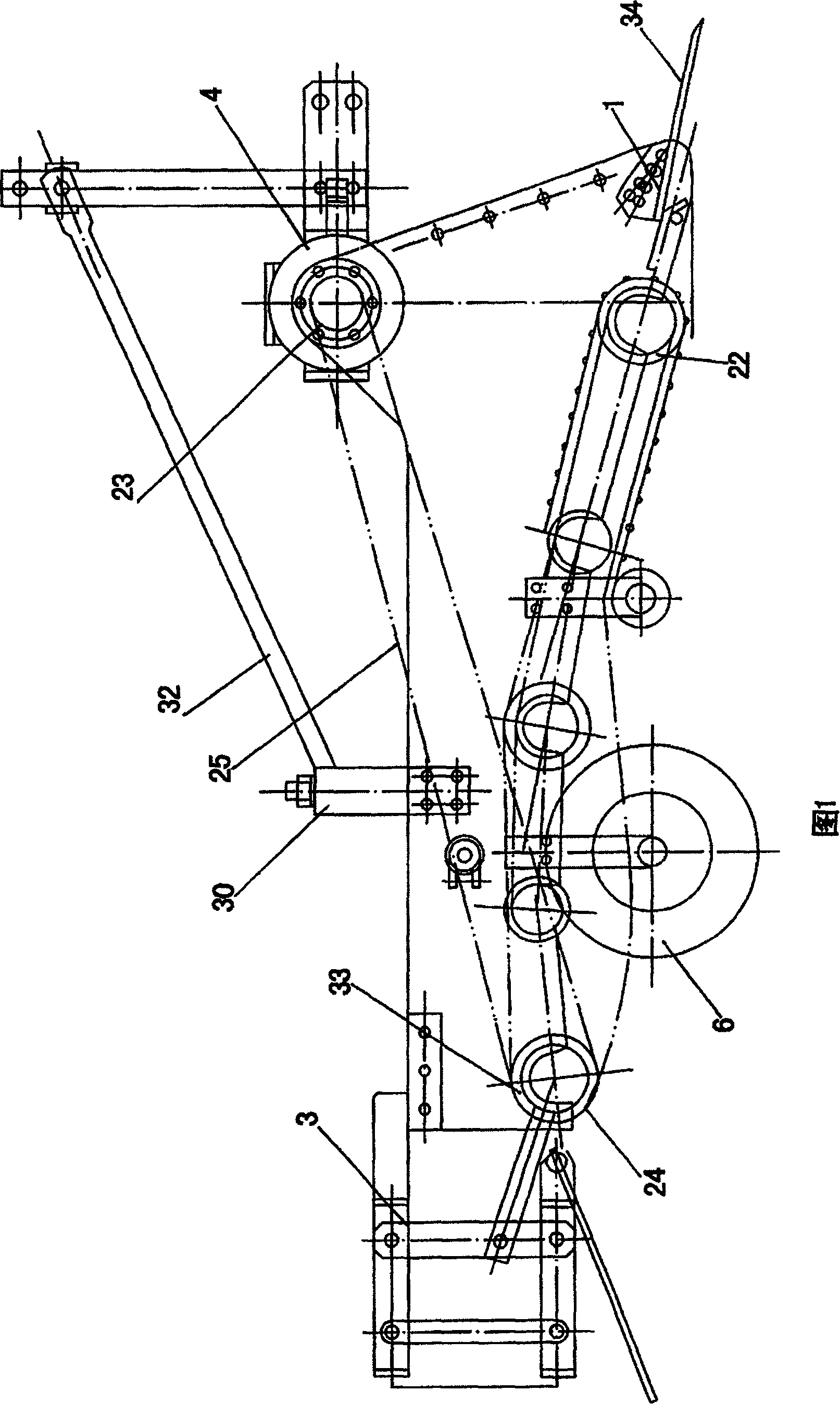

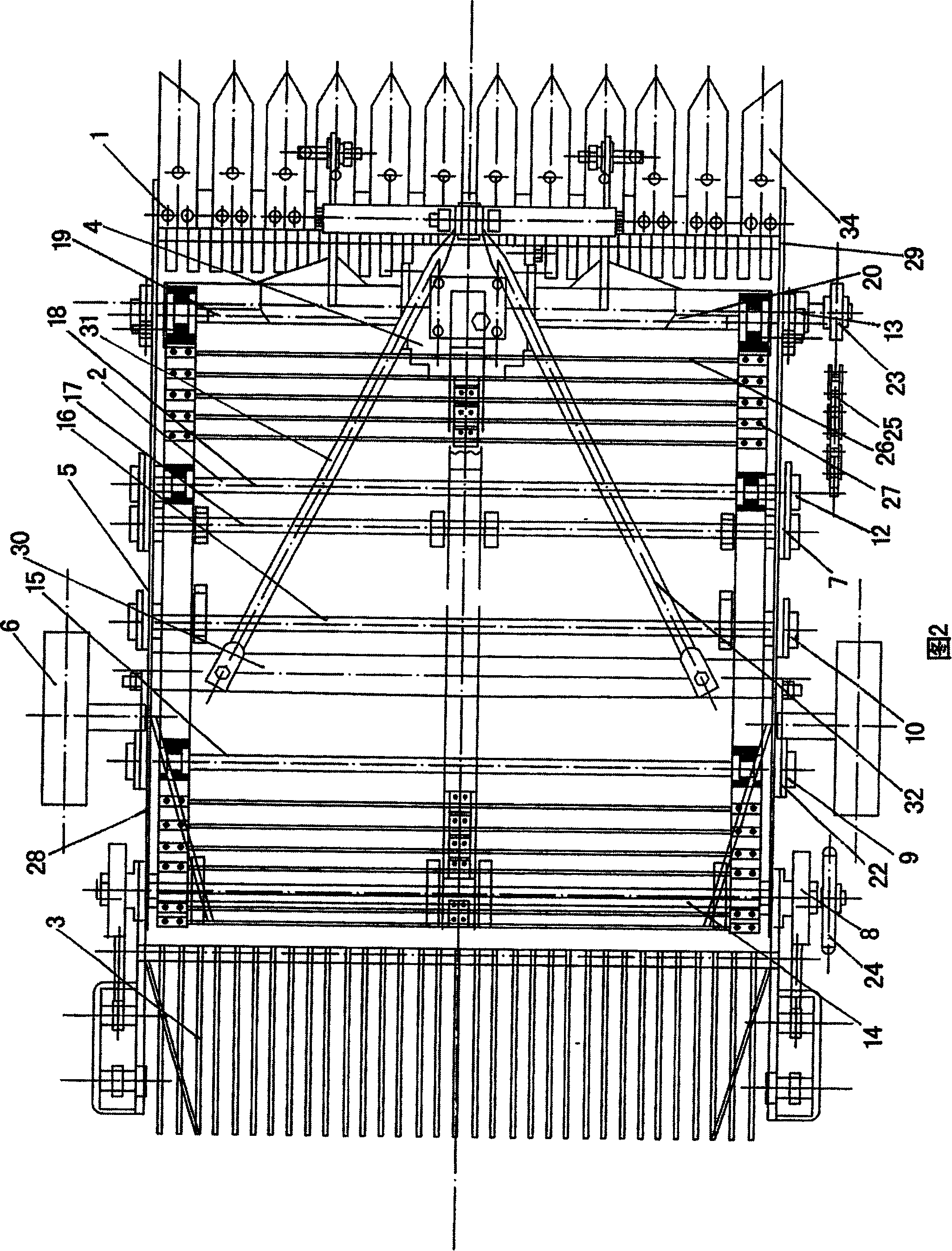

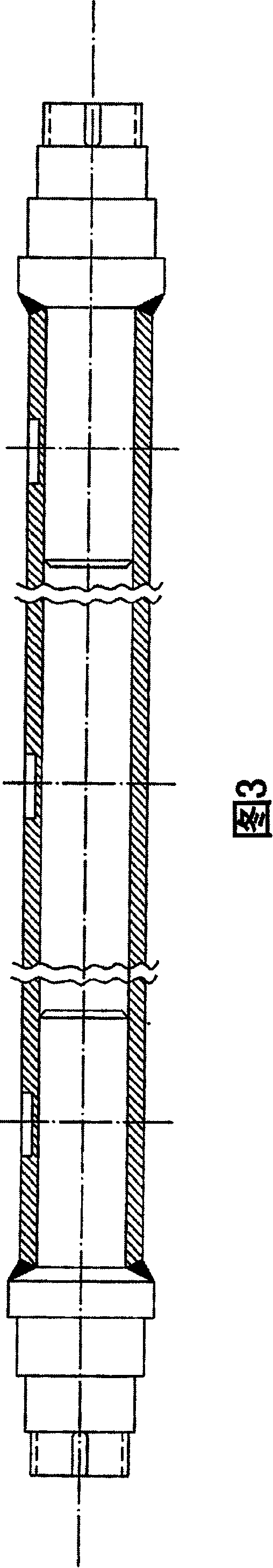

[0019] Embodiment 1: The potato harvester includes: a digging shovel mechanism 1, a bar chain separation mechanism 2, a sieve swing separation mechanism 3, a gearbox transmission mechanism 4, a main frame 5, a road wheel mechanism 6, and a transmission support mechanism 7 The transmission support mechanism includes a transmission wheel 8, a drag chain wheel 9, a shaking wheel 10, a lower drag chain wheel 11, an upper drag chain wheel 12, a guide wheel 13, a transmission shaft 14, a drag chain shaft 15, a shaking shaft 16, and a lower drag chain wheel. Chain shaft 17, upper drag chain shaft 18, guide wheel shaft 19, gearbox output shaft 20; the input shaft 21 of the gearbox is connected with the power output shaft of the tractor, and the sprocket 23 at the output shaft end of the gearbox and the sprocket 24 of the drive shaft pass through the chain 25 Connected; the rod chain separation mechanism 2 includes a rod 26 and a conveyor belt 27, wherein the conveyor belt 27 is in the ...

Embodiment 2

[0020] Embodiment 2: The potato harvester includes: a digging shovel mechanism 1, a bar chain separation mechanism 2, a sieve swing separation mechanism 3, a gearbox transmission mechanism 4, a main frame 5, a road wheel mechanism 6, and a transmission support mechanism 7 The transmission support mechanism includes a transmission wheel 8, a drag chain wheel 9, a shaking wheel 10, a lower drag chain wheel 11, an upper drag chain wheel 12, a guide wheel 13, a transmission shaft 14, a drag chain shaft 15, a shaking shaft 16, and a lower drag chain wheel. Chain shaft 17, upper drag chain shaft 18, guide wheel shaft 19, gearbox output shaft 20; the input shaft 21 of the gearbox is connected with the power output shaft of the tractor, and the sprocket 23 at the output shaft end of the gearbox and the sprocket 24 of the drive shaft pass through the chain 25 Connected; the rod chain separation mechanism 2 includes a rod 26 and a conveyor belt 27, wherein the conveyor belt 27 is in the ...

Embodiment 3

[0021] Embodiment 3: The potato harvester includes: a digging shovel mechanism 1, a bar chain separation mechanism 2, a sieve swing separation mechanism 3, a gearbox transmission mechanism 4, a main frame 5, a road wheel mechanism 6, and a transmission support mechanism 7 The transmission support mechanism includes a transmission wheel 8, a drag chain wheel 9, a shaking wheel 10, a lower drag chain wheel 11, an upper drag chain wheel 12, a guide wheel 13, a transmission shaft 14, a drag chain shaft 15, a shaking shaft 16, and a lower drag chain wheel. Chain shaft 17, upper drag chain shaft 18, guide wheel shaft 19, gearbox output shaft 20; the input shaft 21 of the gearbox is connected with the power output shaft of the tractor, and the sprocket 23 at the output shaft end of the gearbox and the sprocket 24 of the drive shaft pass through the chain 25 Connected; the rod chain separation mechanism 2 includes a rod 26 and a conveyor belt 27, wherein the conveyor belt 27 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com