Deep scarifying, stubble cleaning and soil pulverizing machine

A soil crusher and stubble removal technology, which is applied to clod crushers, agricultural machinery and implements, shovels, etc., can solve the problems of heavy labor, high labor intensity, and inability to remove stubble at the same time, so as to reduce operation resistance and improve operation. effect, the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

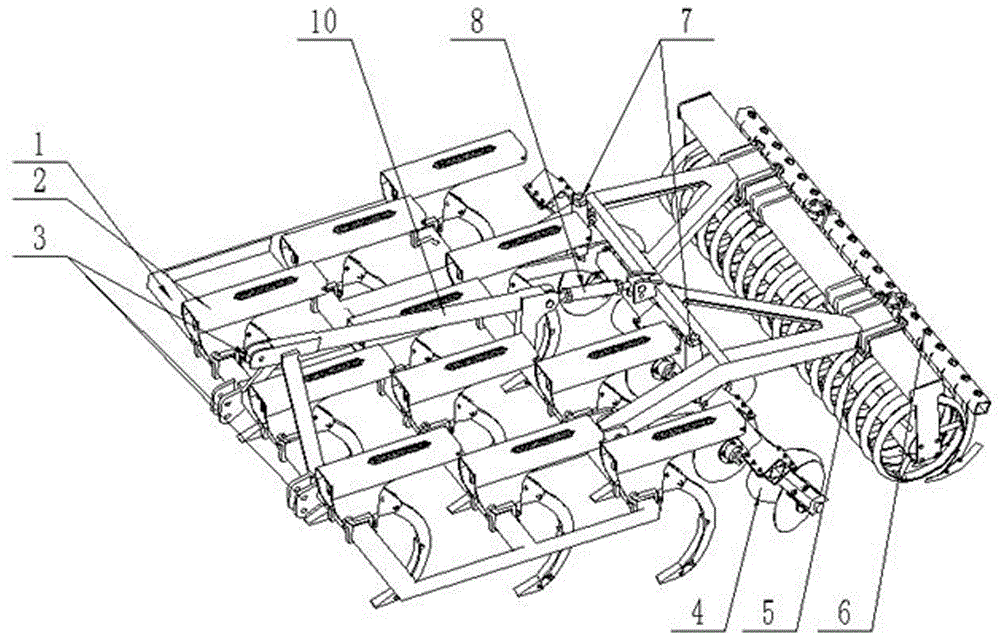

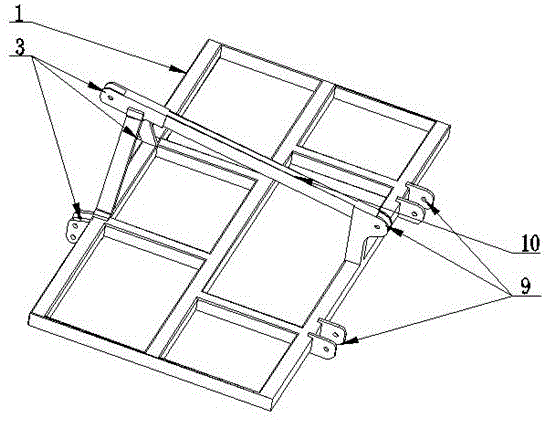

[0026] like figure 1 and figure 2 Shown, a kind of subsoiling stubble breaker comprises large frame 1, three-point suspension device 3 before welding of large frame 1 front end, three-point suspension device 9 after welding of large frame 1 rear end. Weld pull rod 10 between the articulated point on the front three-point suspension device 3 and the articulated point on the rear three-point suspension device 9 . Below the big frame 1 is provided with a subsoiling device 2, and its effect is to deeply loosen the soil.

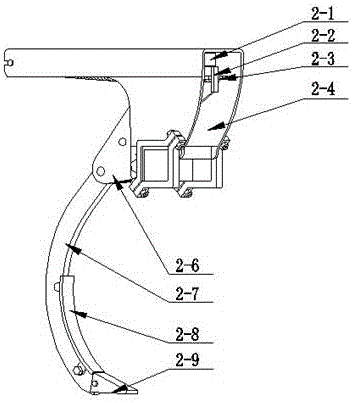

[0027] image 3 , Figure 4 As shown, the subsoiling device 2 includes a subsoiling frame 2-4, and the subsoiling frame 2-4 is fixedly connected with the large frame 1 through an L-shaped card. The subsoiling shovel frame 2-6 and the subsoiling shovel frame 2-4 are hinged by pins, and the lower end of the subsoiling shovel frame 2-6 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com