Gap eliminator for worm and wormwheel

A technology of worm gears and worms, which is applied in hoisting devices, portable lifting devices, belts/chains/gears, etc., can solve the problems of inconvenient adjustment of side clearance, high welding technology requirements, and deformation of worms, etc., and achieves simple structure and high efficiency. Stability, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

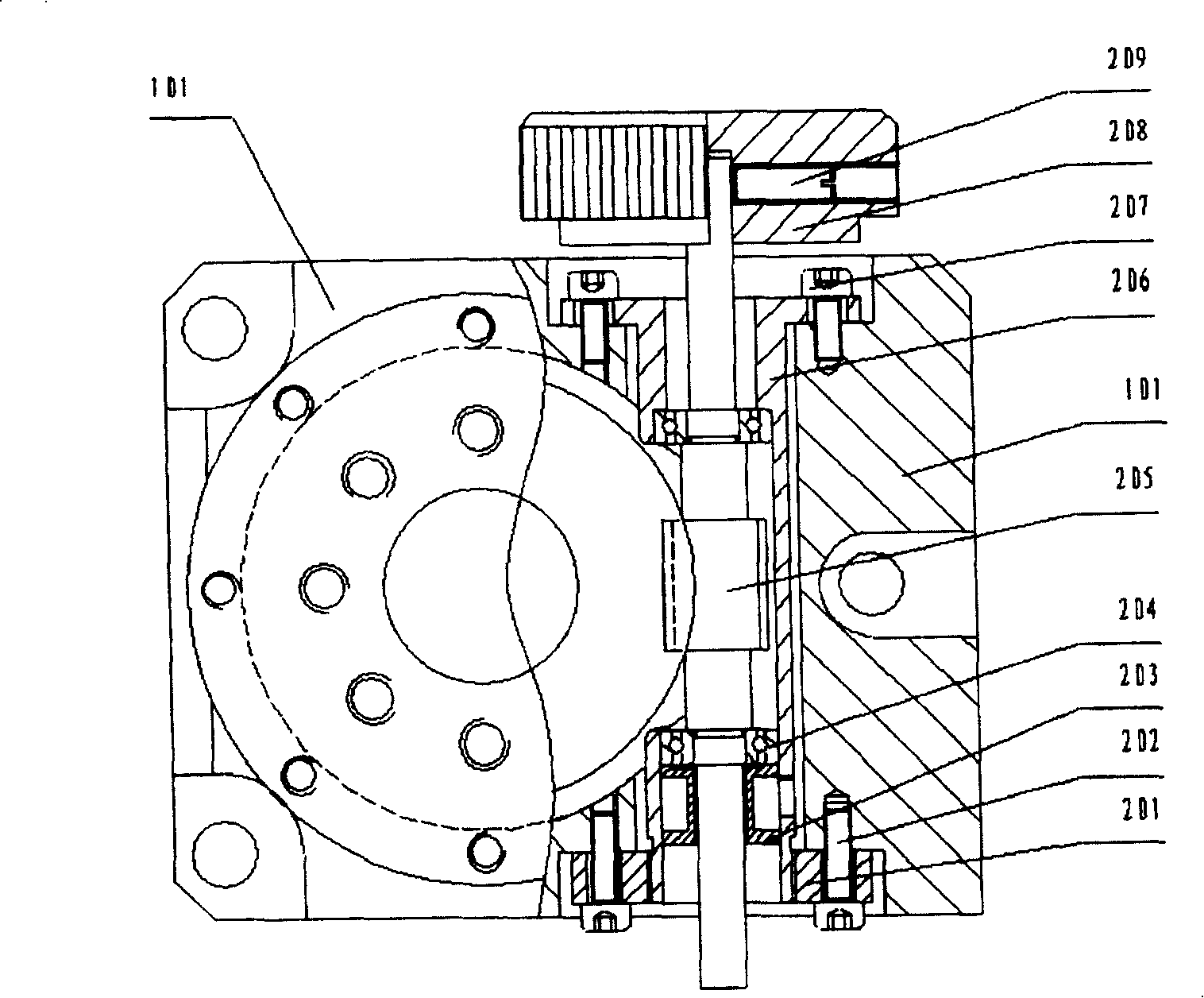

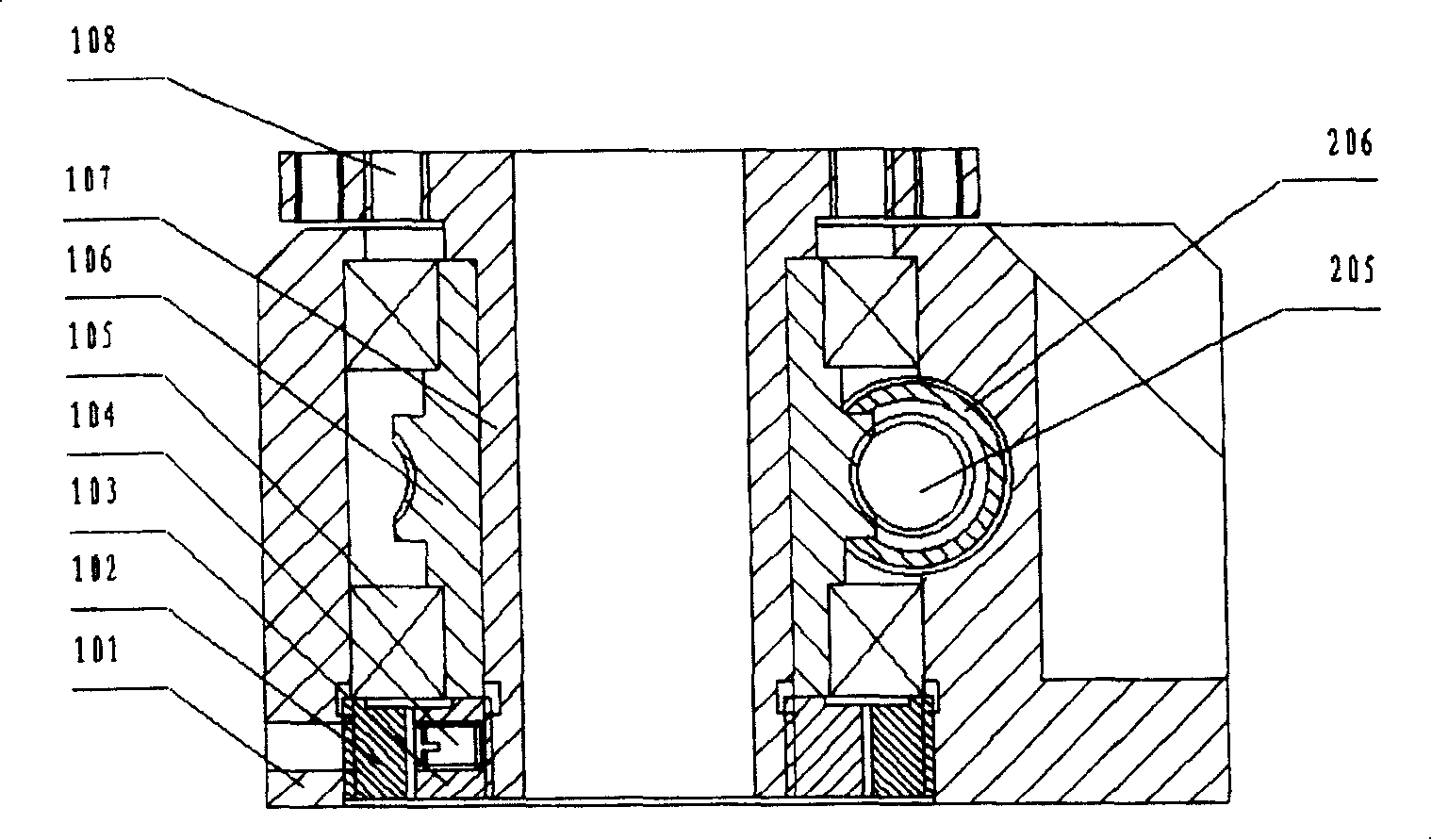

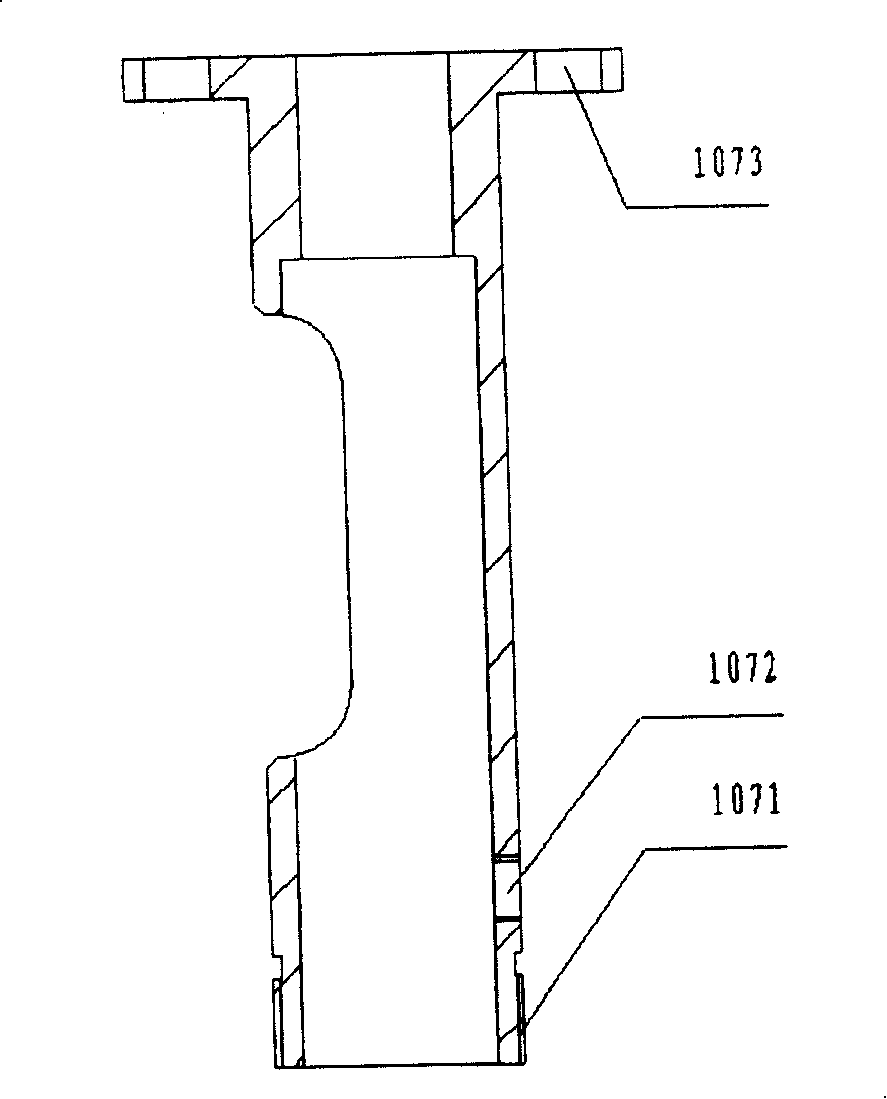

[0016] see figure 1 , figure 2 . figure 1 It is an assembly sectional view of the worm part of the worm gear and worm anti-backlash device of the present invention. It can be seen from the figure that the worm gear and worm anti-backlash device of the present invention includes a worm gear clearance adjustment mechanism and a worm clearance adjustment mechanism. The structural form of the worm gear gap adjustment mechanism is that the rotating body 107 is inserted into the frame body 101 first, and then the worm wheel 106 and the bearings 105 at both ends of the worm wheel (two places) are installed on the frame body 101 and the rotating body 107. Between them, the rotating body pressure ring 103 is installed on the threaded end of the rotating body 107 to compress the worm wheel 106, and then the rotating body pressure ring 103 is fixed with set screws 104. The rotating body pressure ring 103 is a circular ring with threads in the center, and a plurality of threaded holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com