Cylindrical part

A technology of cylindrical parts and cylindrical parts, which is applied in the direction of tubular articles, optical elements, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described below using the drawings.

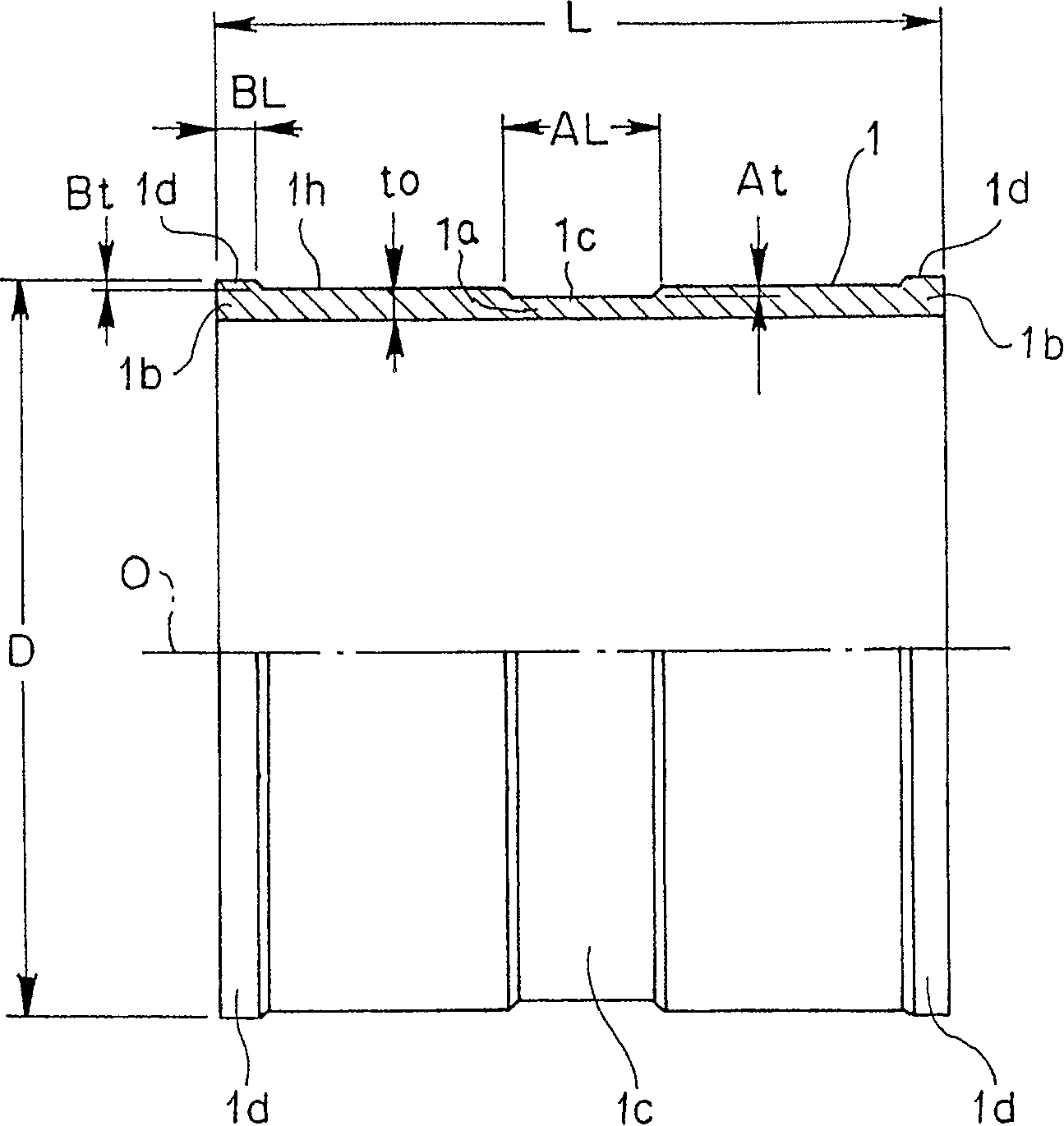

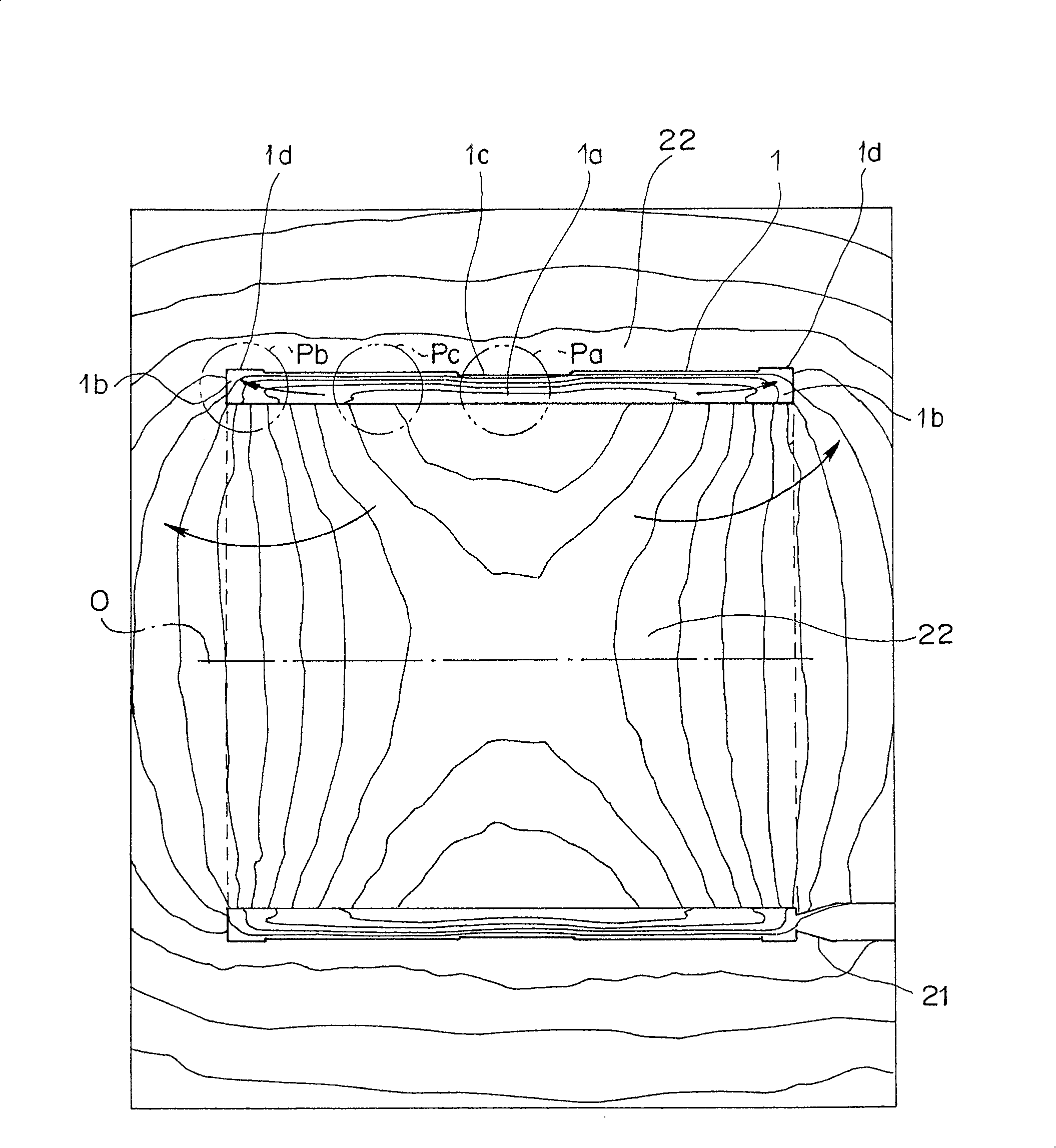

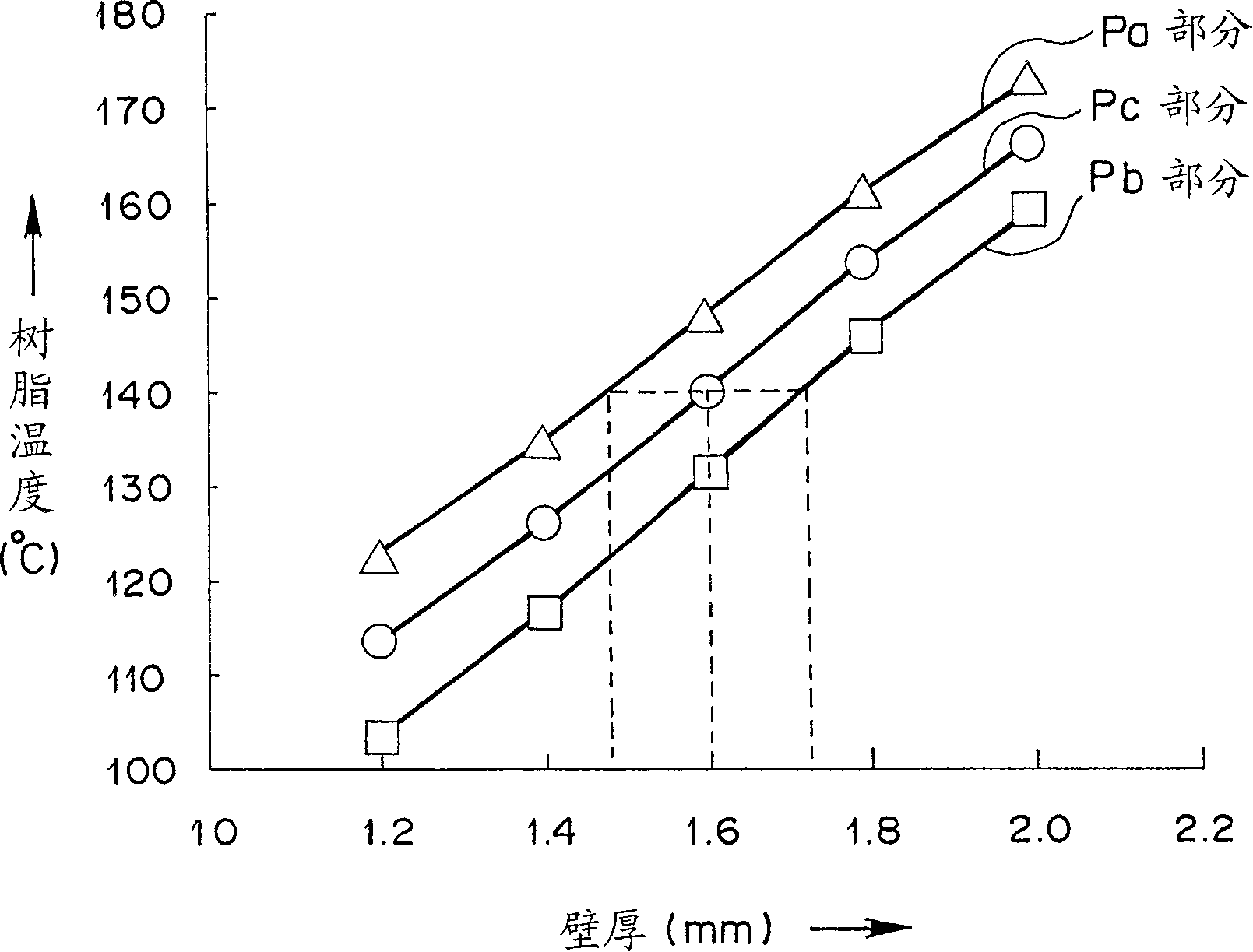

[0047] figure 1 It is a side view showing the upper half of the cylindrical member which is the cylindrical member of the first embodiment of the present invention in section. figure 2 It is a diagram showing the temperature distribution of the mold and the cylindrical member when the cylindrical member is molded and when the resin filling is completed (the direction of the arrow in the figure indicates the direction in which the temperature on the isotherm decreases). image 3 to represent figure 2 A graph showing the relationship between the wall thickness (horizontal axis) of the main part of the cylindrical member and the resin temperature (the temperature of each main part at the end of filling, the vertical axis). Figure 4 This is an enlarged view showing the deformed state of the above-mentioned cylindrical member molding, and is a side view showing the upper half in section. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com