Roller type wedge cross-rolling process of shaping eccentric stepped shaft

A technology of cross wedge rolling and stepped shaft, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problem of unable to form eccentric shaft parts, etc., to improve material utilization, continuous fiber structure, continuous fiber flow line Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

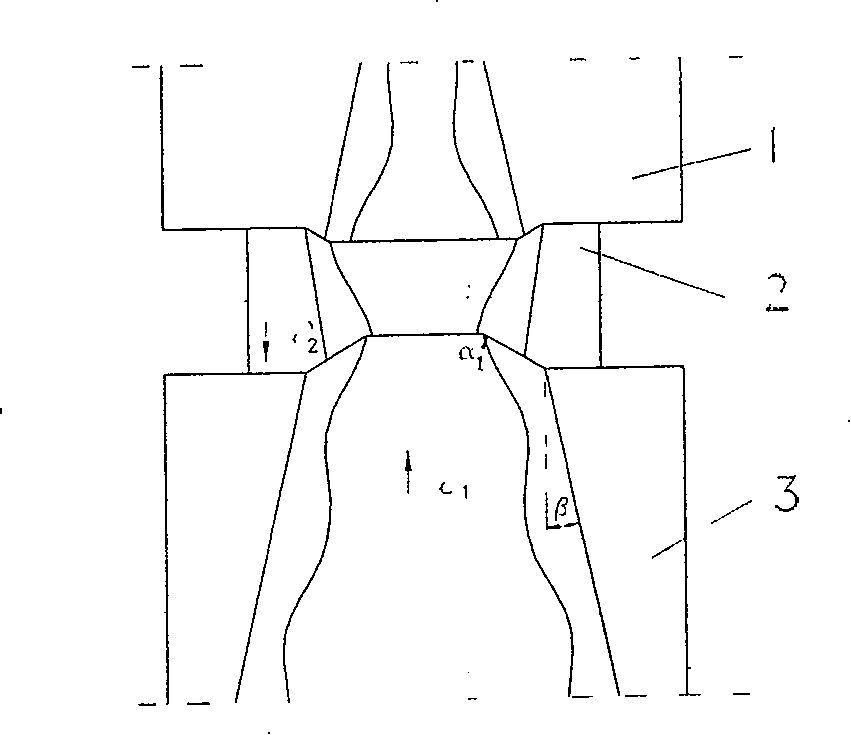

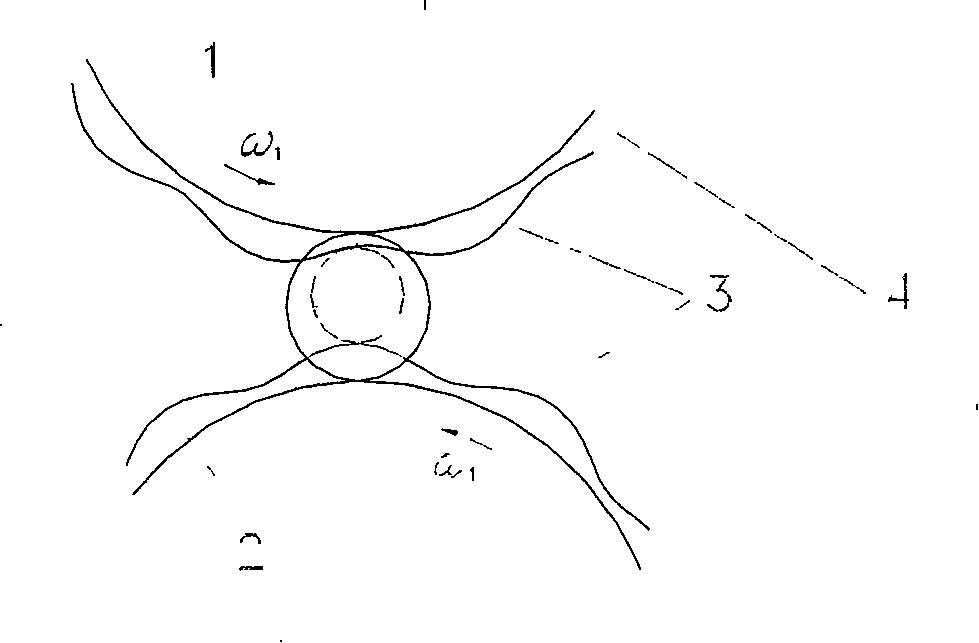

[0039] Figure 10 Shown is an example of roll cross wedge rolling with an eccentric shaft ( Figure 9 Shown) The expansion diagram of the mold pass and the forming process of the eccentric shaft. The billet is placed between two rollers, and the movement of the rollers drives the billet to rotate. Under the action of the mold, the billet is radially compressed and axially extended, and the billet is gradually formed into a stepped shaft. The middle diameter of the forming eccentric shaft of the I-stage die is Φ30mm; the eccentric diameter of the II-stage die on the forming eccentric shaft is Φ33mm; forming at this stage is different from the traditional cross-wedge rolling process, which is the key of the present invention. shaft stage, its longitudinal profile soil such as Figure 10 As shown in (V-V), the wedge shape of the mold corresponding to the eccentric shaft of this section is as follows Figure 4 shown. The diameter of the outermost end of the forming eccentric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com