Wiper blade

A technology of wiper blades and wipers, which is applied in vehicle maintenance, coating, special surfaces, etc., can solve the problems of high cost, high dry friction coefficient, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

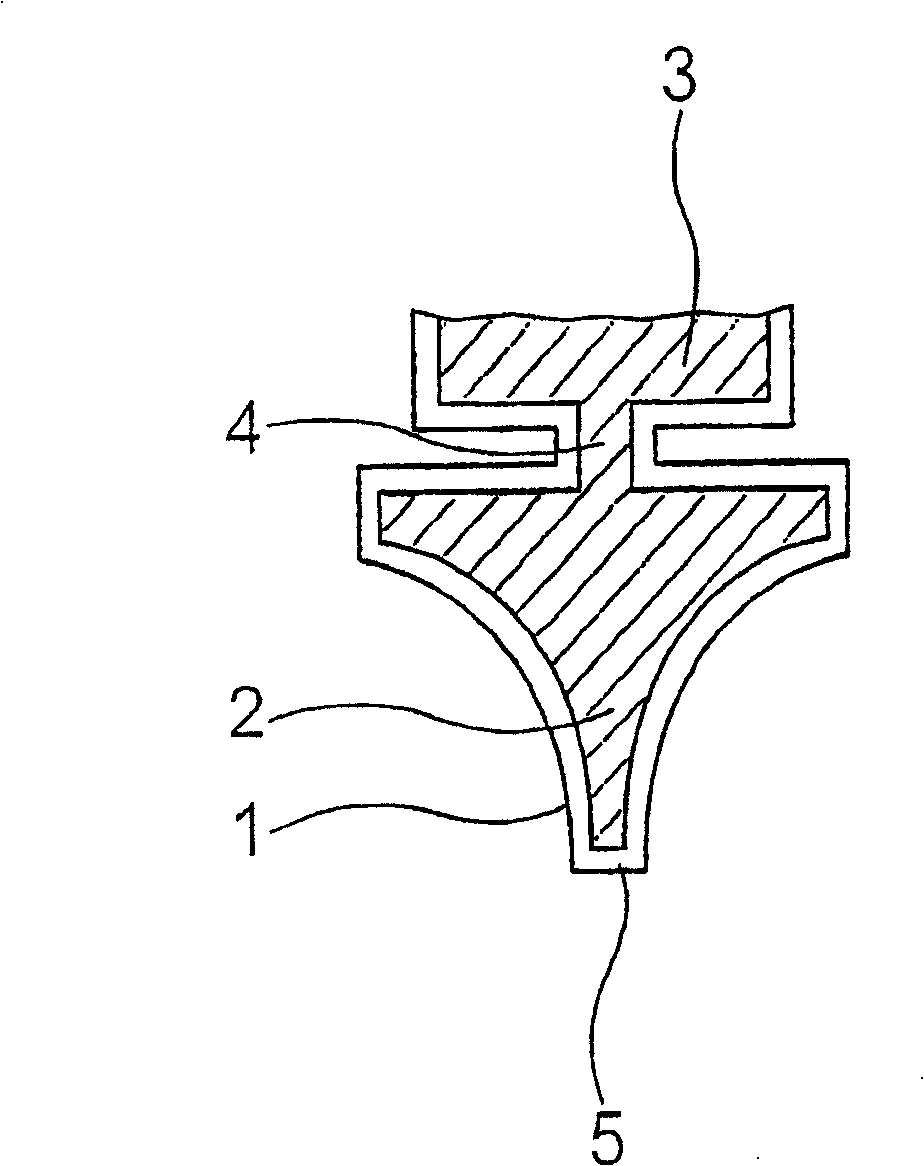

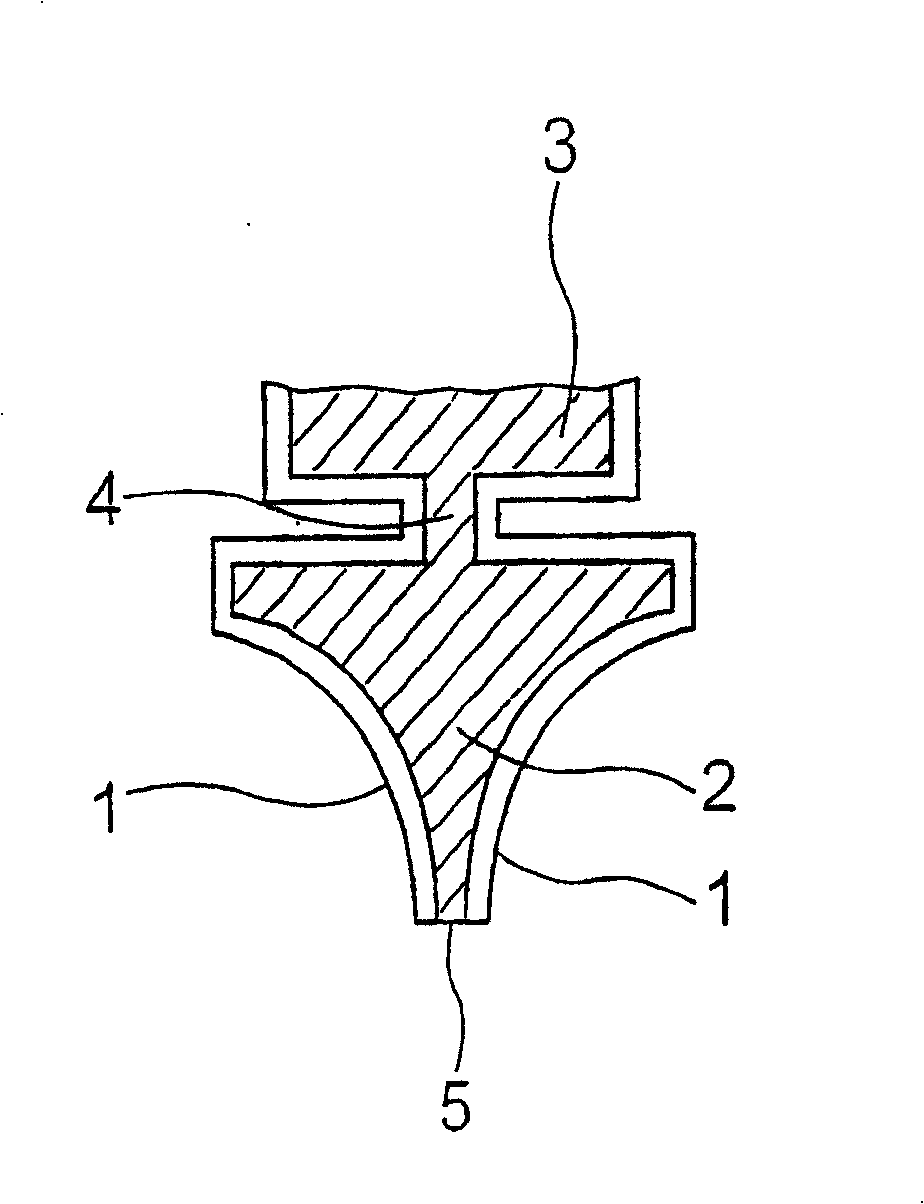

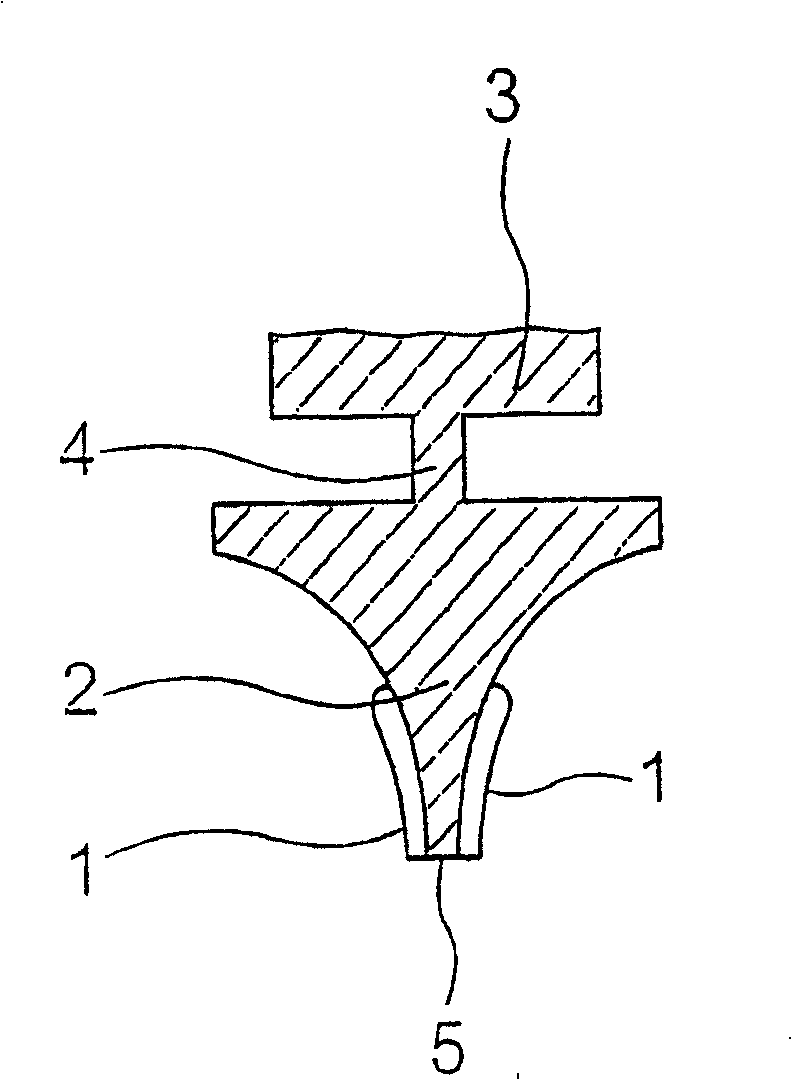

[0029] exist figure 1 shows a wiper blade consisting of a wiper lip 2 made of rubber material and having a wiper edge (Wischkante ) 5; the head part 3 is only partially shown here and is made of rubber material; the switching strip 4 is made of rubber material and is arranged between the head part 3 and the wiper lip 2 .

[0030] The wiper lip 2, the head part 3 and the switching strip 4 are provided with a surface which consists of a layer of polyethylene 1, which is shown in the figure 1 In the middle, the wiper lip 2 , the head part 3 and the switch strip 4 are shown enlarged compared to the wiper lip 2 . The polyethylene layer 1 is currently made of PE-UHMW, that is to say of polyethylene with an ultra-high molar mass.

[0031] according to figure 1 The wiper blades are produced by first extruding partially vulcanized rubber material in an extruder with the aid of a tool in a wiper blade mold, then sprinkled with PE-UHMW powder and subsequently vulcanized. The conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com