A method and device for inert gas-assisted purification of OLED materials or intermediates thereof

An inert gas and intermediate technology, applied in chemical instruments and methods, luminescent materials, organic chemistry, etc., can solve the problems of large surface area, unfavorable acquisition of high-purity OLED intermediates or products, and rapid product precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

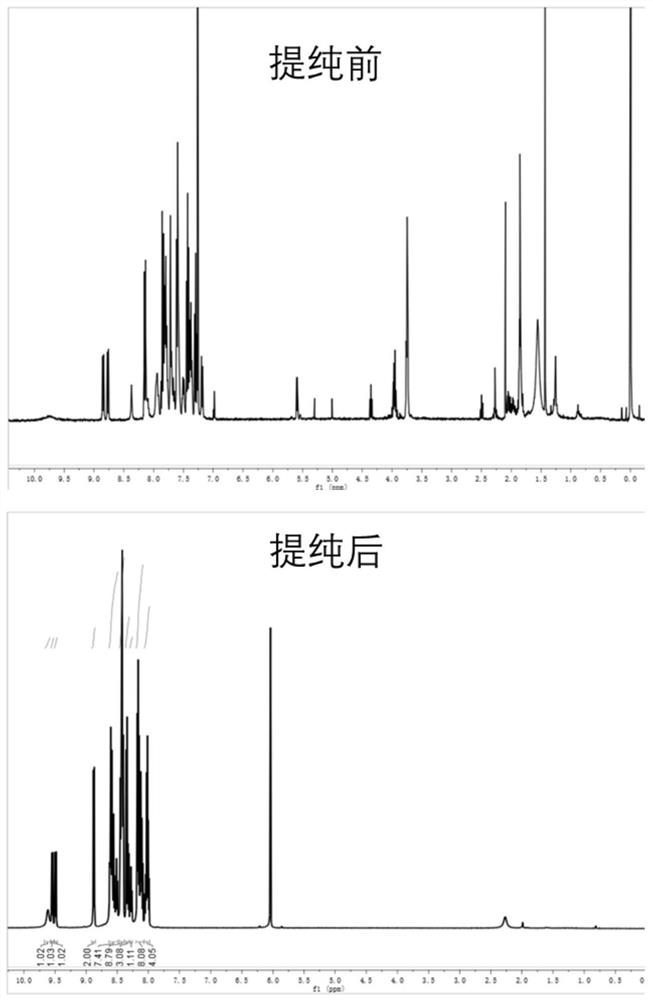

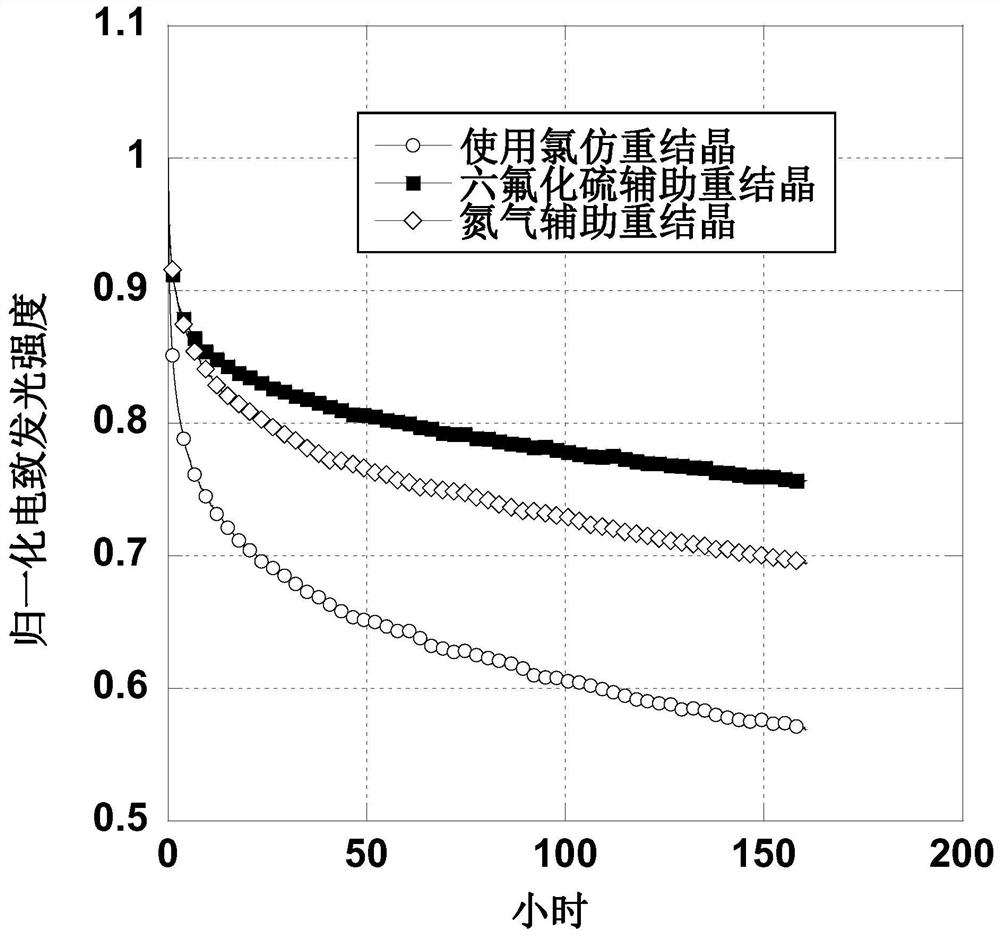

[0033] Purification of small molecule blue light material M1 based on phenanthroimidazole

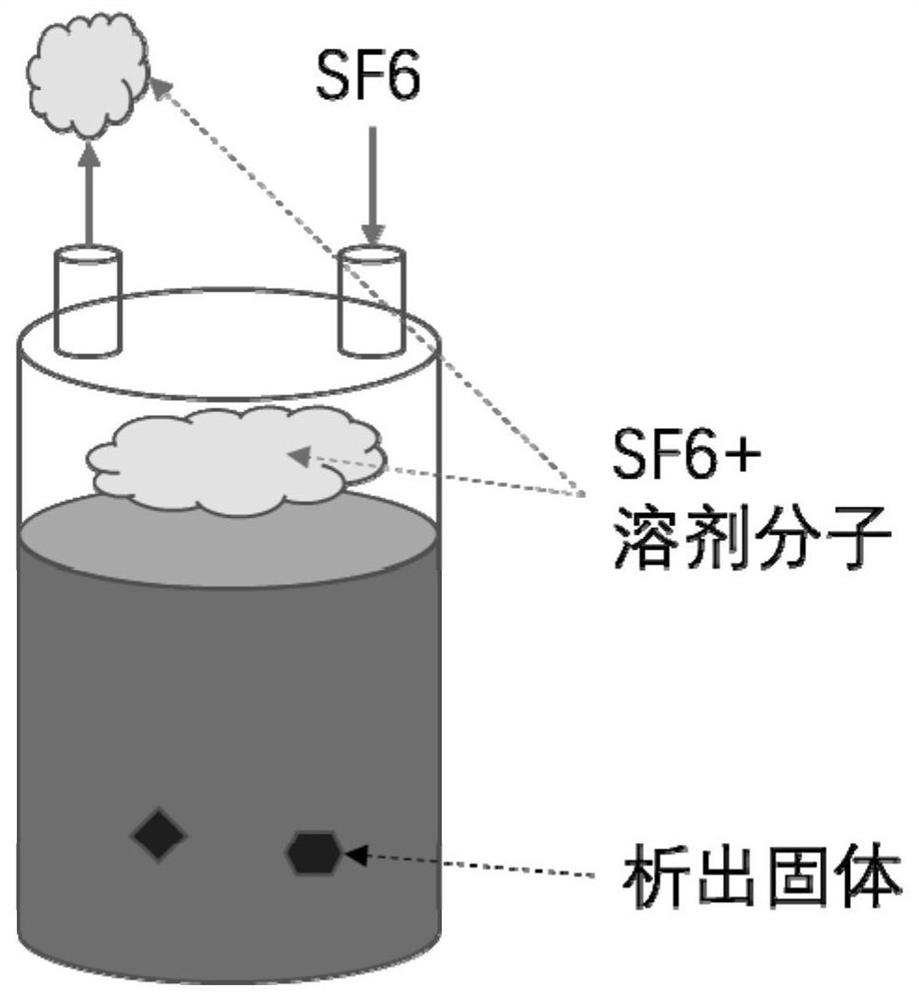

[0034] Weigh 600mg of the crude product, purchased from Alda New Materials Co., Ltd., dissolve in a mixed solvent of 30ml of dichloromethane and 15ml of methanol, place it in a 50ml vacuum buffer bottle, and connect the air inlet on the left side to the absorber of the sulfur hexafluoride cylinder. The pressure valve is connected in series with the gas flow meter, and the gas outlet on the right side is connected to the oil-sealed gas buffer bottle to prevent sucking back.

[0035] Control the pressure reducing valve and adjust the gas flow rate to v through the gas flow meter 0 =180ml / min ventilation for 30min, and according to v(t)=v 0 *(1+0.25[t / 30]) regulates the gas flow rate, where v(t) is the gas flow rate at t(min), v 0 is the initial flow rate, which is 180ml / min here, and t is the moment, calculated from the start of inflation, and the unit is minute.

[0036] Until the vol...

Embodiment 2

[0040] Purification of small molecule blue light material M2 based on benzyne

[0041] Weigh 500mg of the crude product, purchased from Alda New Materials Co., Ltd., dissolve in a mixed solvent of 15ml of dichloromethane and 20ml of methanol, place it in a 50ml vacuum buffer bottle, and connect the air inlet on the left to the absorber of the sulfur hexafluoride cylinder. The pressure valve is connected in series with the gas flow meter, and the gas outlet on the right side is connected to the oil-sealed gas buffer bottle to prevent sucking back.

[0042] Control the pressure reducing valve and adjust the gas flow rate to v through the gas flow meter 0 =180ml / min ventilation for 0.5h, and according to v(t)=v 0 *(1+0.25[t / 30]) regulates the gas flow rate, where v(t) is the gas flow rate at t(min), v 0 is the initial flow rate, here it is 180ml / min, t is the moment, calculated from the start of inflation, and the unit is minute.

[0043] Until the volume of the solution in th...

Embodiment 3

[0047] Purification of small molecule blue light material M3 based on phenanthroimidazole

[0048]Weigh 800mg of crude product, purchased from Arda New Materials Co., Ltd., dissolve in a mixed solvent of 20ml acetone and 20ml ethanol, place it in a 50ml vacuum buffer bottle, and connect the left air inlet to the pressure reducing valve of the sulfur hexafluoride cylinder The gas flowmeter is connected in series, and the gas outlet on the right is connected to the oil-sealed gas buffer bottle to prevent sucking back.

[0049] Control the pressure reducing valve and adjust the gas flow rate to v through the gas flow meter 0 =270ml / min ventilation for 0.5h, and according to v(t)=v 0 *(1+0.25[t / 30]) regulates the gas flow rate, where v(t) is the gas flow rate at t(min), v 0 is the initial flow rate, here it is 270ml / min, t is the moment, calculated from the start of inflation, and the unit is minute.

[0050] Until the volume of the solution reaches between 20 and 25ml, white c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com