Stereo operation fast fragments discharging method in mine drifting

A three-dimensional, operational technology, applied in earth drilling, transportation and packaging, underground transportation, etc., can solve the problems of low work efficiency, cost, and low cost, and achieve the effects of easy implementation, improved mucking efficiency, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

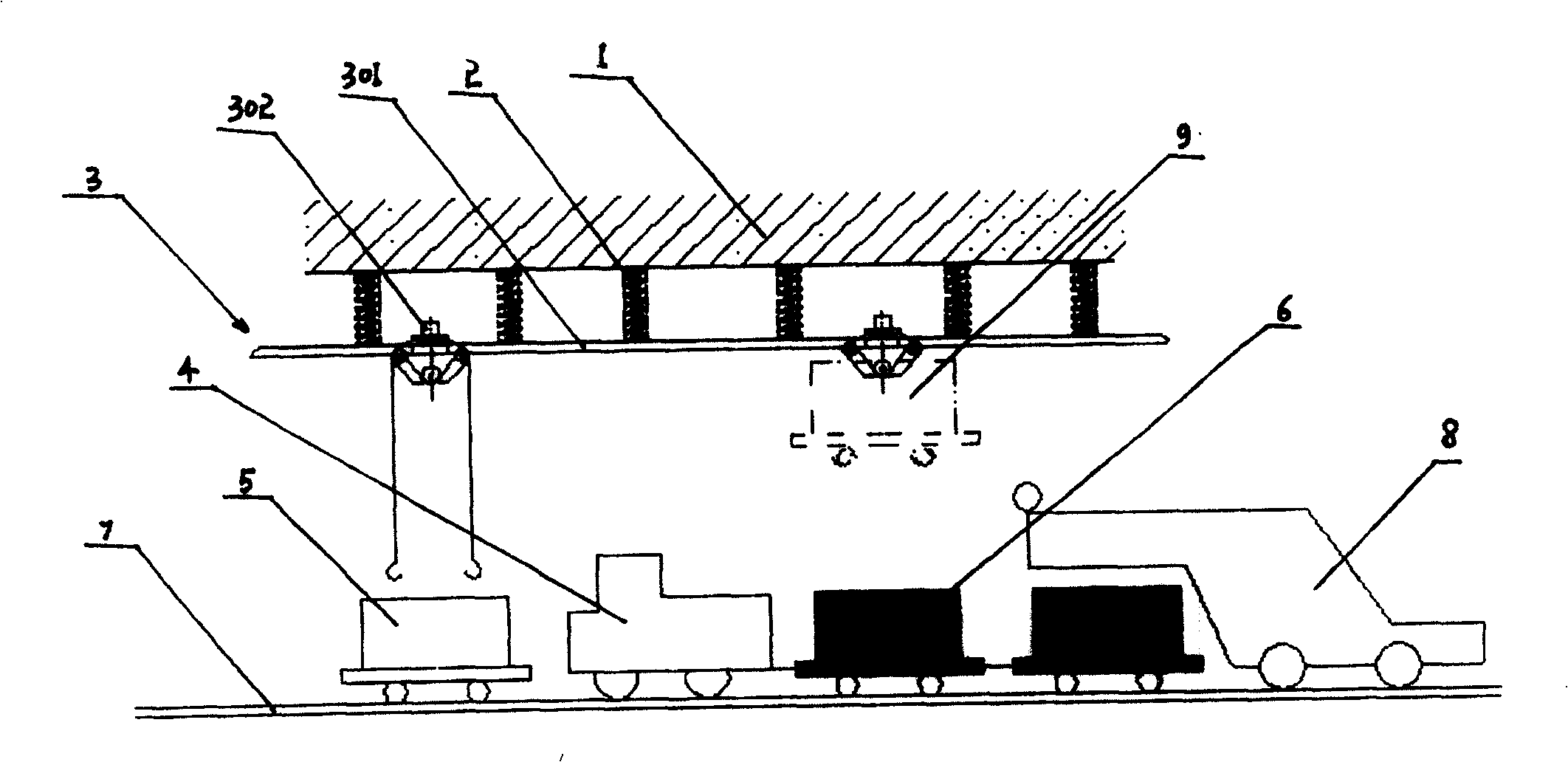

[0019] Embodiment 1, in conjunction with referring to figure 2 , a method for fast mucking out of three-dimensional operations in mine excavation, its related equipment and structures mainly include: a monorail crane 3 suspended on the roadway vault 1 anchor rod 2, an electric locomotive 4, an empty wagon (empty wagon) 5, a heavy Car 6, ground track 7, pick-up machine 8, etc. The monorail crane 3 is composed of a monorail 301 connected by sections of I-beams and a set of hoisting mechanism 302. Some existing mining machinery factories (such as Shijiazhuang Coal Machinery Factory) produce a series of cranes for other high-altitude operations. The "monorail crane" products in the field can be directly selected as the monorail crane 3 of this embodiment. The monorail crane 3 is hoisted on the anchor rod 2 of the vault 1, and the operating state of its hoisting mechanism can be operated by wireless remote control. Way.

[0020] Its working steps and process are: when the ballas...

Embodiment 2

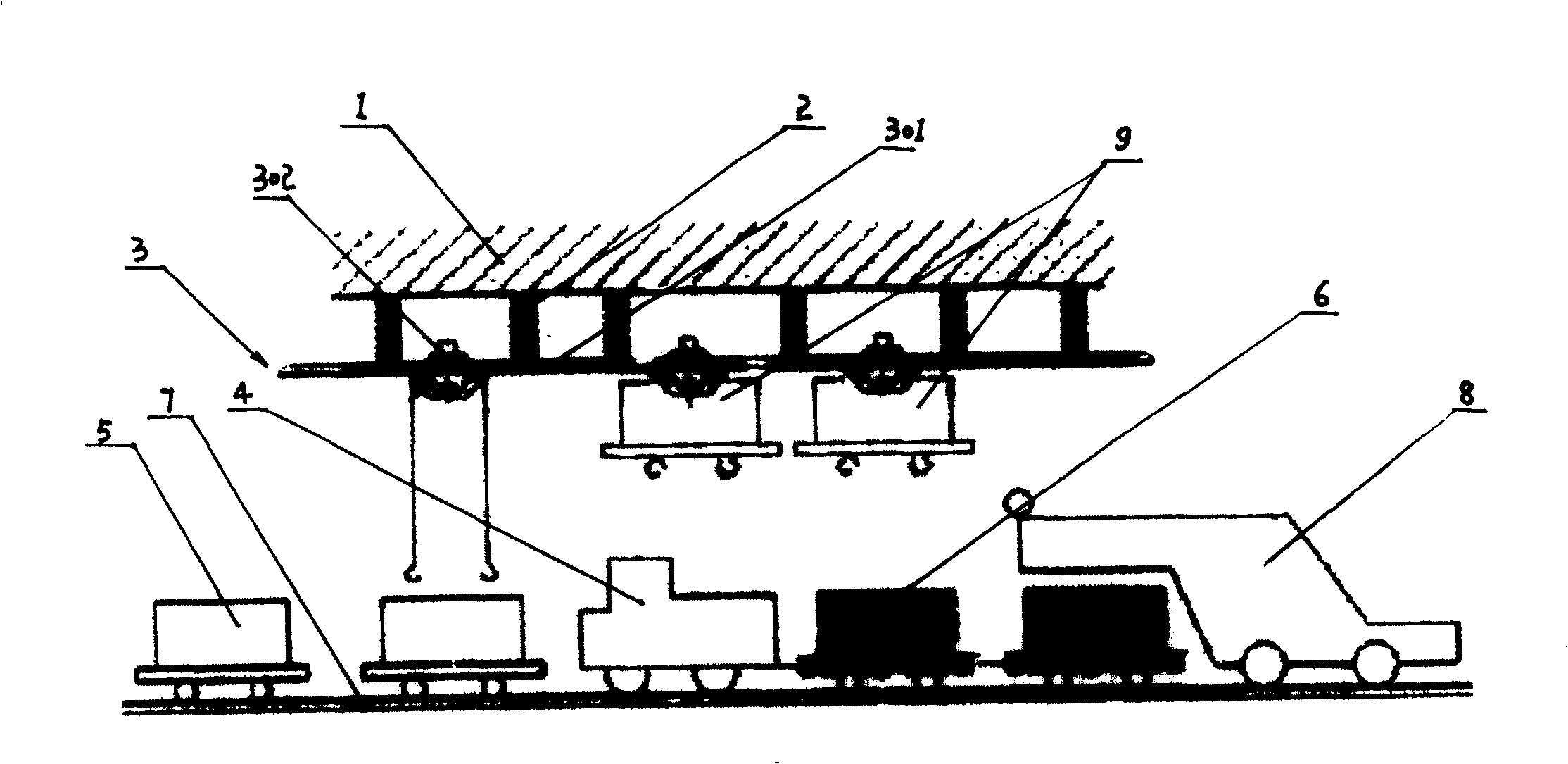

[0022] Embodiment 2, see in conjunction with image 3 , a method for quickly removing muck in three-dimensional operations in mine excavation, its related equipment and structures mainly include: monorail crane 3 suspended on the roadway vault 1 bolt 2, electric locomotive 4, empty car 5, heavy car 6, ground Track 7, pick-up machine 8, etc. The monorail crane 3 is composed of a monorail 301 connected by sections of I-beams and a set of hanging mechanism 302. Some existing mining machinery factories (such as Shijiazhuang Coal Machinery Factory) produce a series of cranes for other transportation. For the "monorail crane" products in the field of work, this type of molded product can be directly selected as the monorail crane 3 of this embodiment. The monorail crane 3 is hung on the anchor rod 2 of the vault 1, and the operating state of its hanging mechanism can be controlled by wireless remote control. mode of operation.

[0023]Its working steps and process are: when the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com