Mucking and transporting method and device applied to double-shield tunnel boring machine

A technology of tunnel boring machine and double shields, which is applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problem of mismatch between efficiency and belt transportation efficiency, and achieve the effect of improving the efficiency of ballast removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

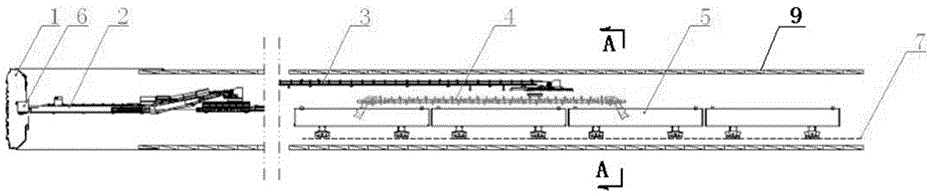

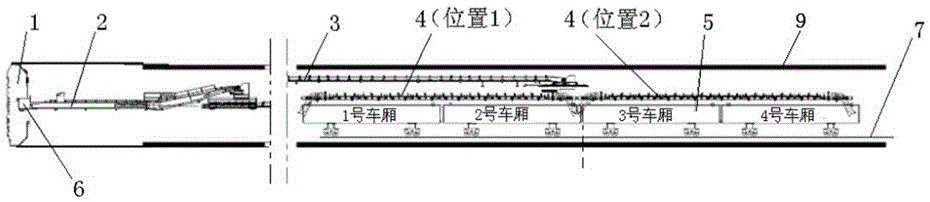

[0027] see Figure 1-Figure 4 , the present invention is a kind of dregs conveying method applied to double-shield tunnel boring machine,

[0028] Include the following steps:

[0029] (1) Use the main belt conveyor 2 to transfer the excavated cutter head 1 to the second belt conveyor 3;

[0030] (2) The second belt conveyor 3 transports the ballast to the fabric belt conveyor 4;

[0031] (3) The distribution belt conveyor 4 distributes the ballast into different compartments of the ballast truck 5 by moving back and forth along the track 7 and switching the direction of rotation.

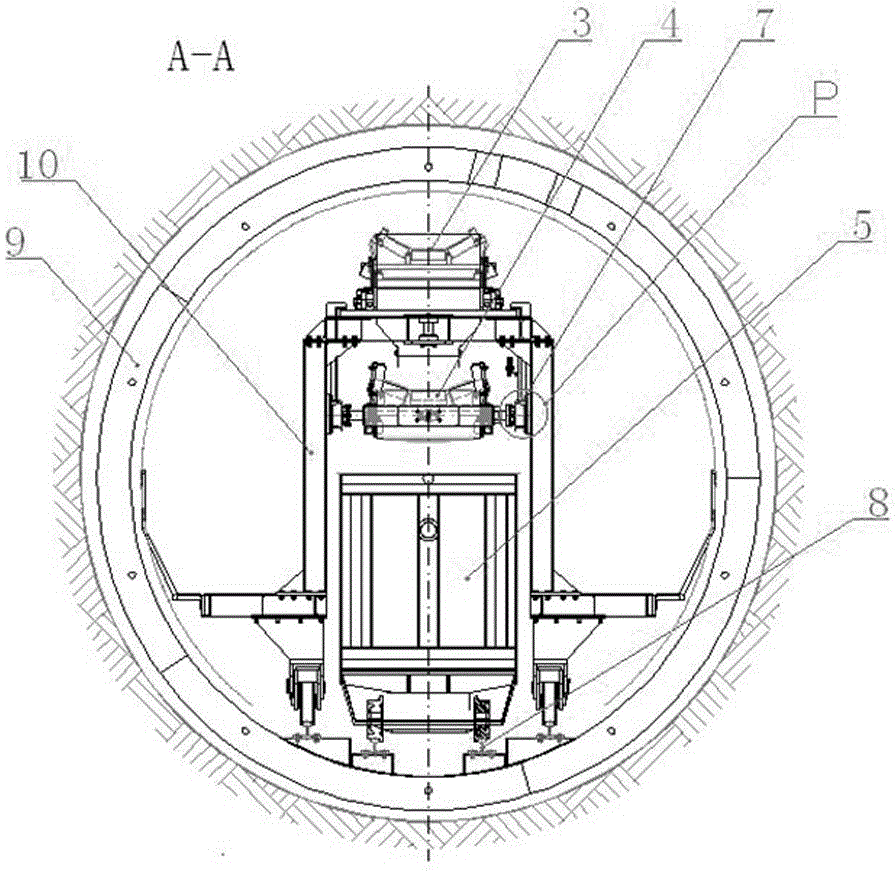

[0032] The whole slag removal system that the present invention adopts comprises main belt conveyor 2, second belt conveyor 3, slag transport vehicle 5 and trolley 10, and the tail end of main belt conveyor 2 is corresponding to the head end of second belt conveyor 3, and the second belt conveyor 3 Belt conveyor 3 is installed on the top of n-shaped trolley 10, and trolley track is provided belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com