Detection apparatus for girdle bounce of valve of air cylinder cover

A cylinder head and valve technology, applied in the direction of angle/taper measurement, etc., can solve the problems of limited production efficiency, inconvenient movement, inconvenient detection, etc., and achieve the effect of improving production efficiency, easy to move, and convenient to detect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

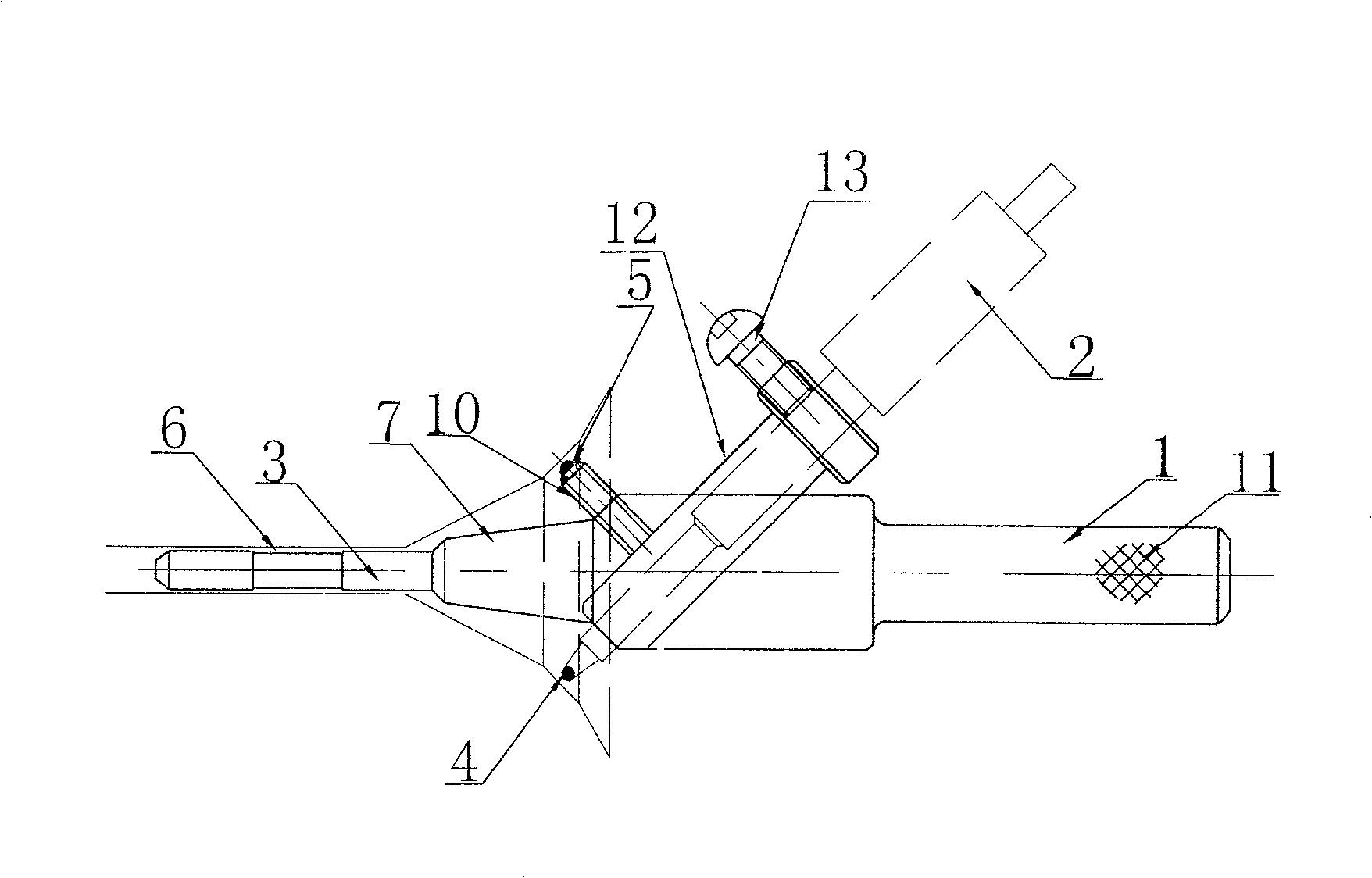

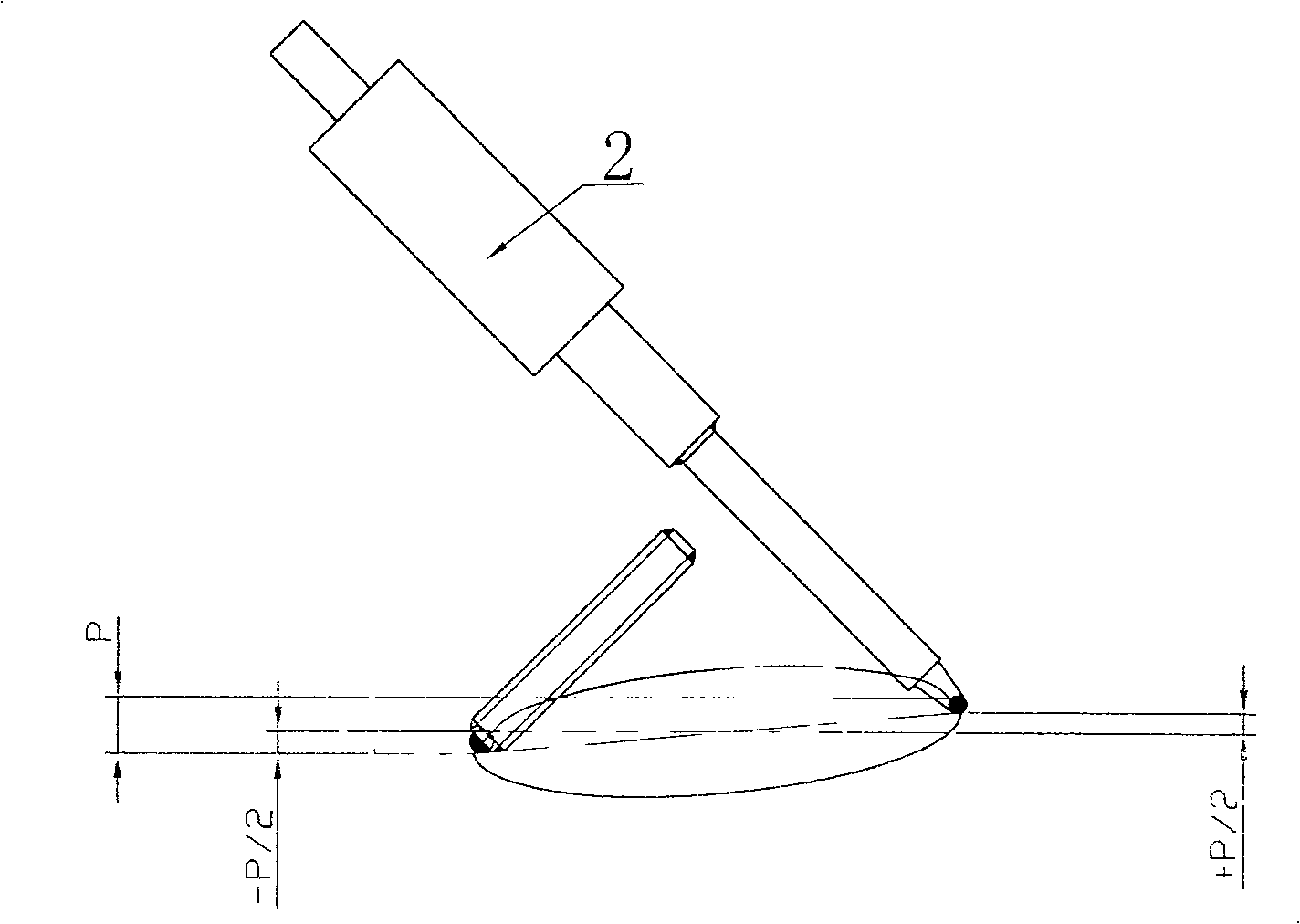

[0018] Embodiment 1: as figure 1 As shown, the inspection tool includes a inspection body 1 and a dial indicator 2. The outer surface of the inspection body 1 is provided with a grid-shaped groove 11. The front end of the inspection body 1 is provided with a cylinder 3 matching the valve guide. The cylinder 3 is provided with An annular groove 6 coaxial with the cylinder 3 . A transition section 7 is provided between the inspection body 1 and the cylinder 3, and the transition section 7 is in a conical structure, the small end of which is connected to the cylinder 3, and the large end is connected to the inspection body 1. The positioning steel ball 5 is arranged at the end of the sleeve 10, the sleeve 10 and the axis of the cylinder form an angle of 45°, the positioning steel ball 5 and the end of the dial indicator contact 4 are roughly located on the same circle, and the center of the circle is extended on the axis of the cylinder Wire.

[0019] The middle section of the ...

Embodiment 2

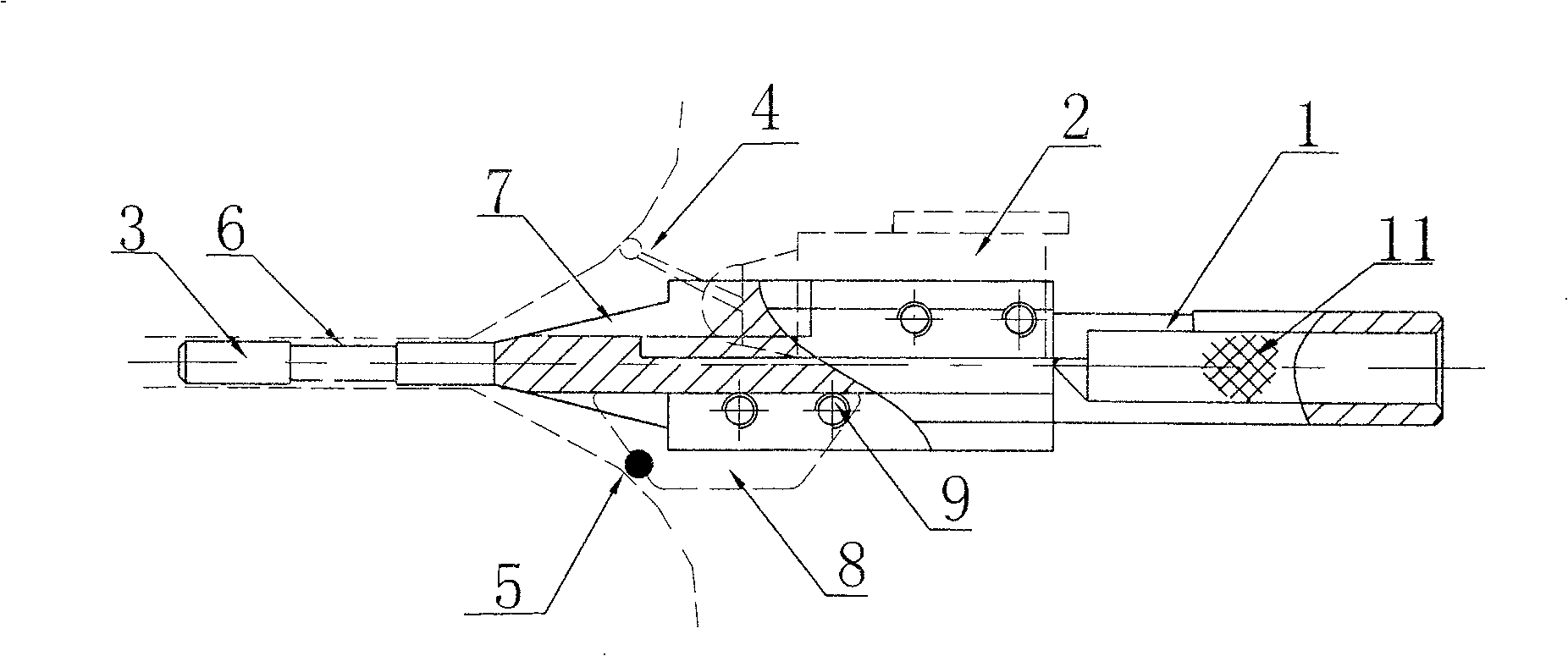

[0022] Embodiment 2: as image 3 As shown, the inspection tool includes a inspection body 1 and a dial indicator 2. The outer surface of the inspection body 1 is provided with a grid-shaped groove 11. The front end of the inspection body 1 is provided with a cylinder 3 matching the valve guide. The cylinder 3 is provided with An annular groove 6 coaxial with the cylinder 3 . A transition section 7 is provided between the inspection body 1 and the cylinder 3, and the transition section 7 is in a conical structure, the small end of which is connected to the cylinder 3, and the large end is connected to the inspection body 1. The positioning steel ball 5 is arranged on the sliding positioning block 8, and the sliding positioning block 8 is slidingly connected with the inspection body 1 and positioned by the positioning screw 9. The axis of the connecting rod and the front end cylinder 3 form 45°, the positioning steel ball 5 and the end of the dial indicator contact 4 are roughl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com