Die pressing plastic ski and its production process

A manufacturing method and snowboard technology, which can be applied to snowboards, skis, and other household appliances, can solve the problems of poor product fusion, unstable sliding, and poor protection, and achieve simple manufacturing methods, flexible turning, and reduced friction coefficients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

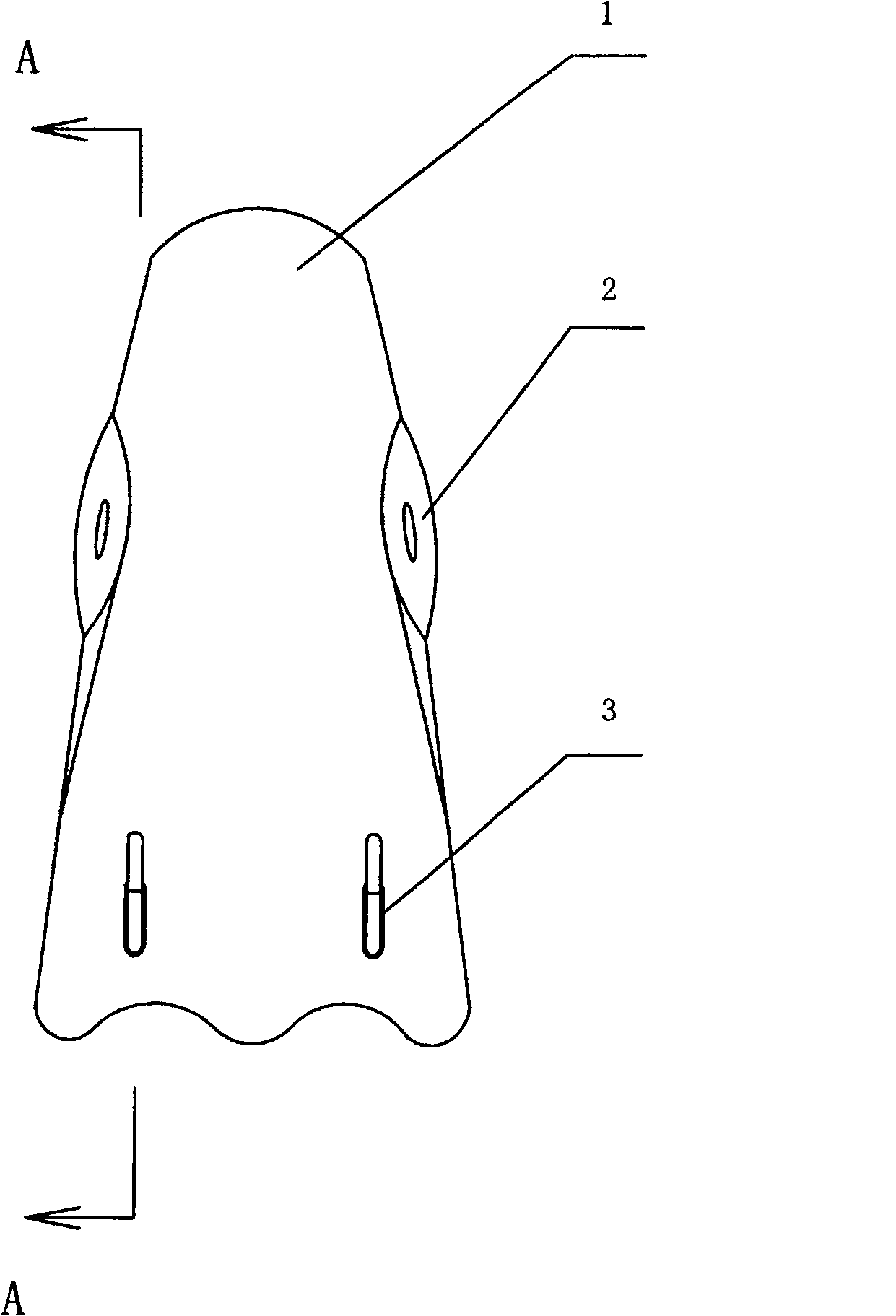

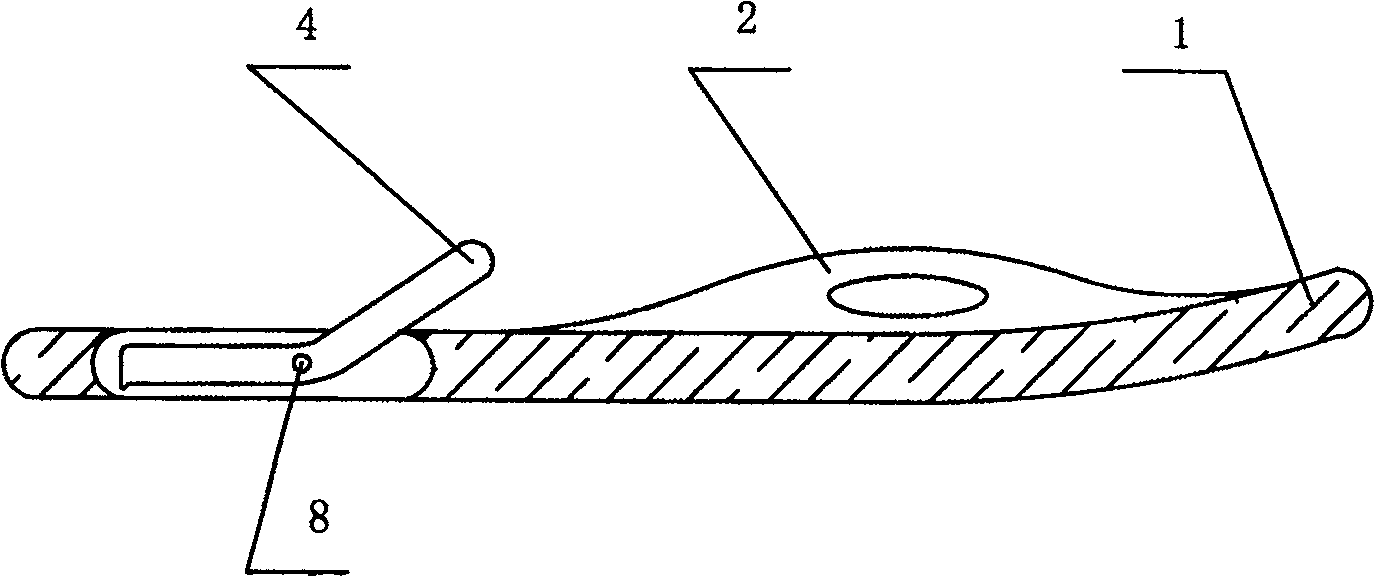

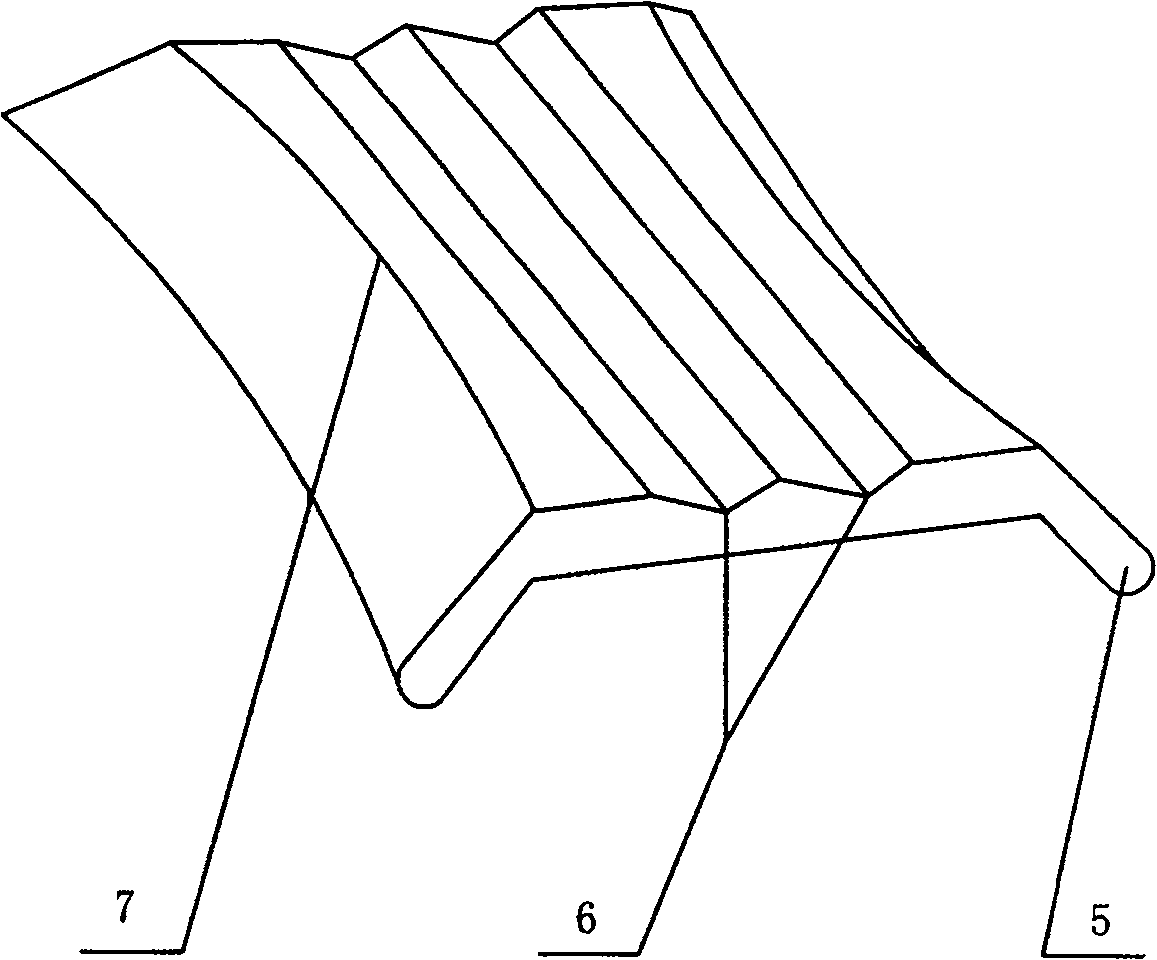

[0028] Such as Figures 1 to 3 Shown is a molded plastic snowboard, the front end 1 of the snowboard is upturned, the two sides 5 of the snowboard are upturned, the two sides are provided with handrails 2, and the handrails 2 are integrated with the snowboard. The afterbody of this snowboard is provided with braking device 3, and this braking device 3 comprises the through-hole on deck chair type hockey stick 4 and skis, and the bending place of this hockey stick 4 is provided with shaft 8, and this hockey stick 4 is connected on by shaft 8 In the through hole of the ski. The bottom surface of the snowboard is provided with two adjacent chute 6, the sliding edge where the two chute 6 intersects, and the edge where the chute 6 intersects with the bottom surface jointly play the role of acceleration and direction control; the bottom surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com