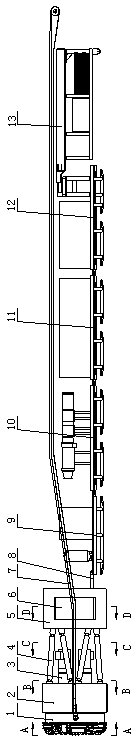

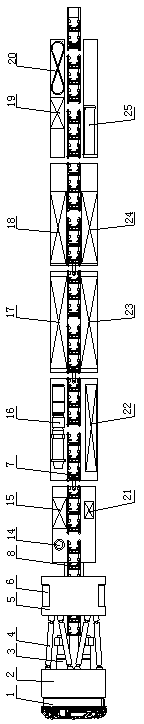

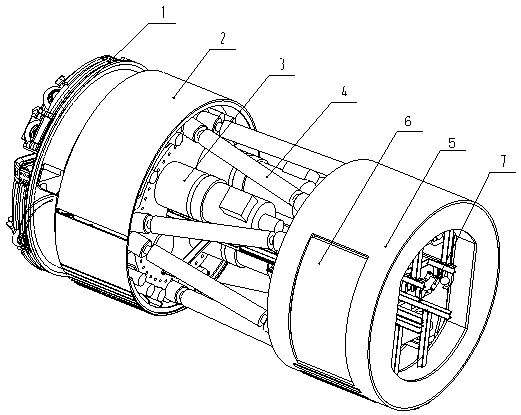

Roadheader and construction method thereof

A technology of roadheader and propulsion mechanism, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of low excavation efficiency in small turns, achieve reasonable equipment layout, improve tunneling efficiency, and improve the construction environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0036] Embodiment 3, the construction method of the boring machine described in embodiment 2, steps are as follows:

[0037] S1: When the roadheader is excavating: first, the propulsion cylinder 4 is in the retracted state, and the shoe mechanism 6 is braced against the cave wall at high pressure, relying on the friction between the right shoe 601 and the left shoe 603 and the wall, to provide a driving force for the excavation. The machine provides the propulsion support reaction force during excavation; then the upper front shield 201 is braced tightly on the cave wall at low pressure to reduce the vibration of the host machine generated during the excavation process; the drive system 3 works to drive the cutter head 1 to rotate; then, the propulsion cylinder 4 stretches out at high pressure , to push the split front shield 2 and the cutter head 1 to dig forward; the rock cut by the cutter head 1 is transported to the tail of the boring machine by the belt conveyor 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com