Optical film and tis producing method and polaroid lens

A manufacturing method and technology of optical film, applied in the field of polarized lenses, can solve problems such as increased birefringence and optical axis deviation, light leakage, and difficulty in preventing light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

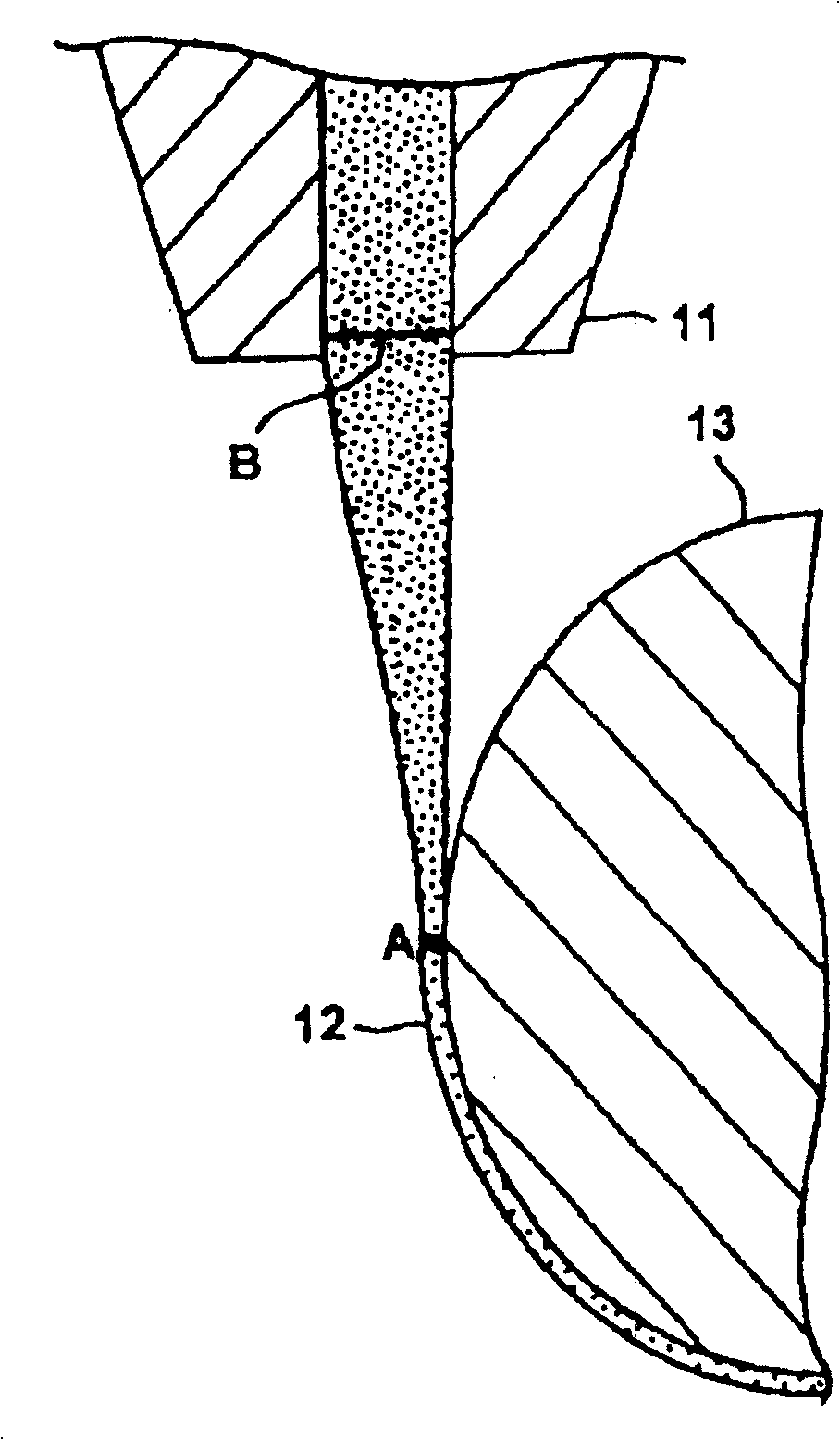

Method used

Image

Examples

example 1 to 9 and comparative example 1 and 2

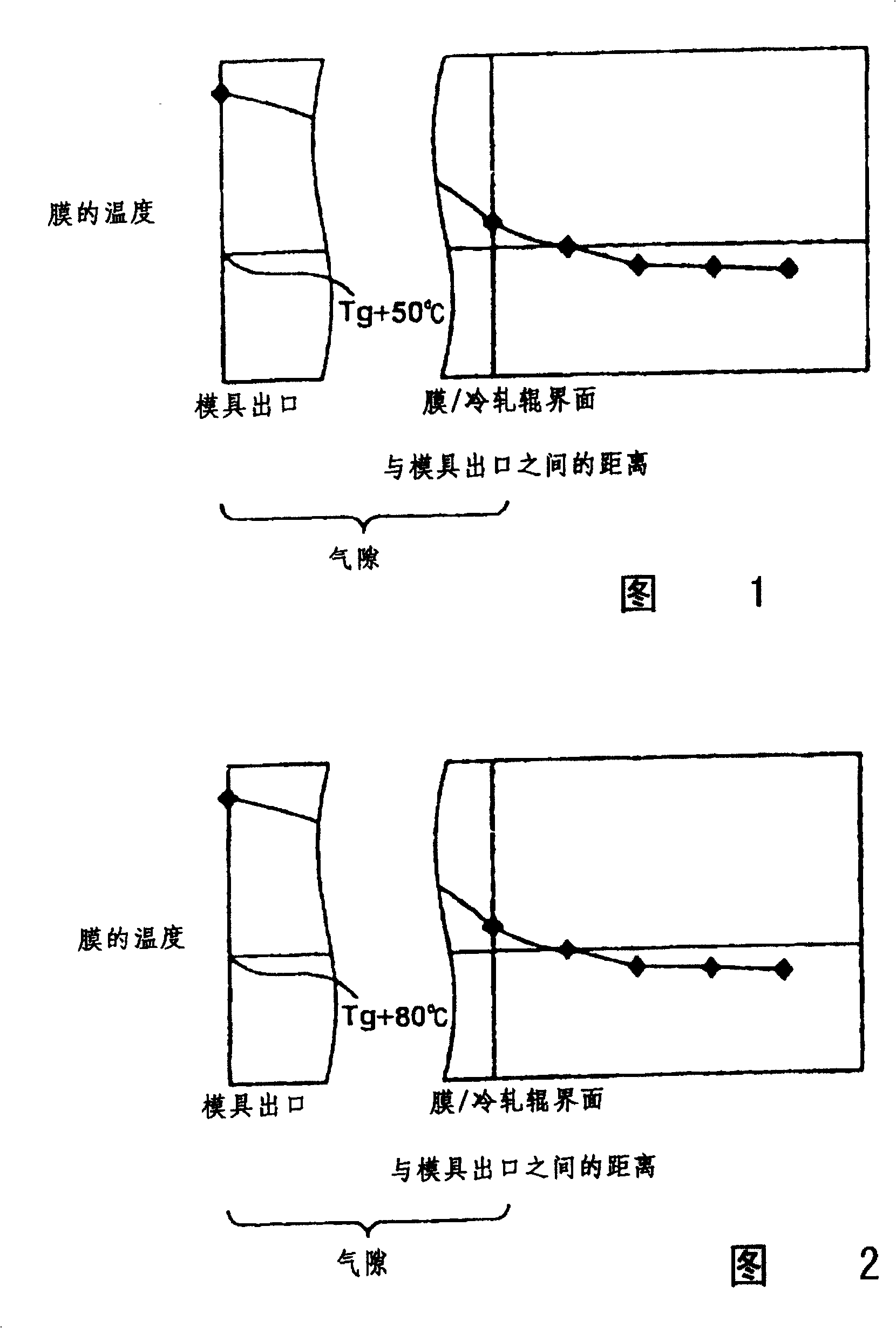

[0123] Retardation and optical axis deviation are given below as values measured with an automatic birefringence analyzer "ROBRA-21ADH" (manufactured by Oji Scientific Instruments) with a ray wavelength of 590 nm. Specifically, cut off the ends opposite to the width of the film that respectively extend the total width of the film by 10%, and measure the retardation of all test points arranged at intervals of 50mm in the width direction of the film, and test the retardation of all test points arranged at intervals of 1m in the direction of flow. The delay of the test point, and calculate the arithmetic mean value of the test value, thus get the delay value. The optical axis deviation is indicated by the angle with the largest absolute value among the angles between the orientation angle of the film and its flow direction.

[0124] (1) Resins used include: manufactured by IECN Corporation, product name "IEDNDR1600", Tg = 168 ° C saturated norbornene resin and Teijin-Amoco Eng ...

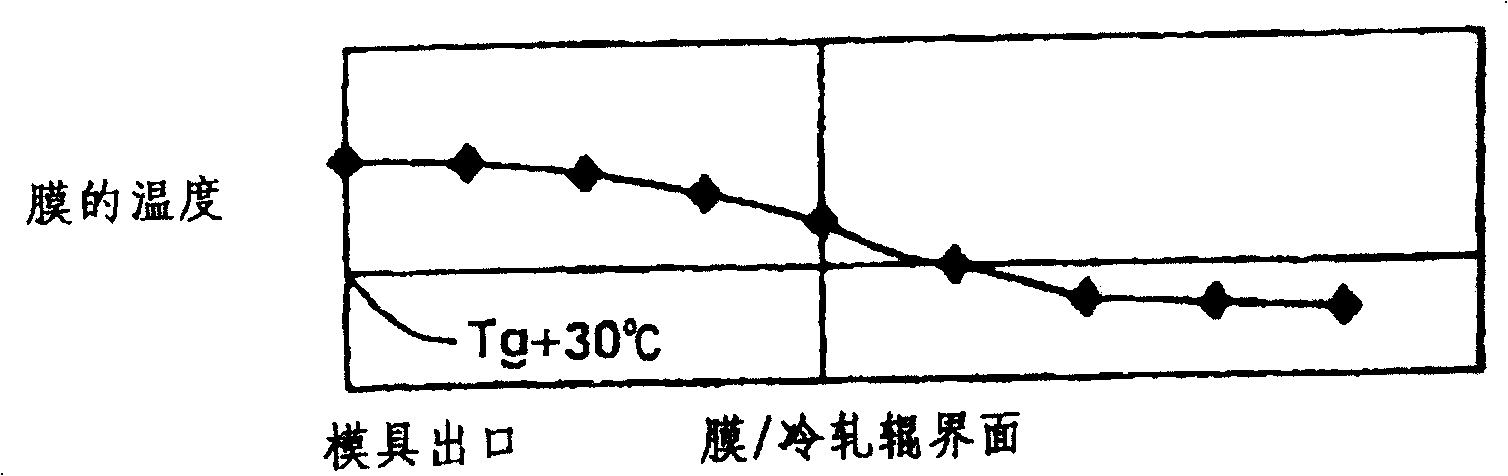

example 1

[0130] The saturated norbornene resin was extruded under the condition that the mold temperature was 220° C. and the air gap was 80 mm. The temperature of the film immediately before contacting the chill roll measured with a radiation thermometer was 310°C. The average value of the remaining retardation of the produced film was 9.50 nm, and the deviation of the optical axis was 7°.

example 2

[0132] The saturated norbornene resin was extruded under the condition that the mold temperature was 310° C. and the air gap was 70 mm. The temperature of the film just before it came into contact with the chill roll was 250°C. The average value of the remaining retardation of the produced film was 2.75 nm, and the deviation of the optical axis was 7°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com