Filling device and method

A technology of filling device and metering device, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, and can solve problems such as difficult adjustment, increased filling loss, and inappropriate filling volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

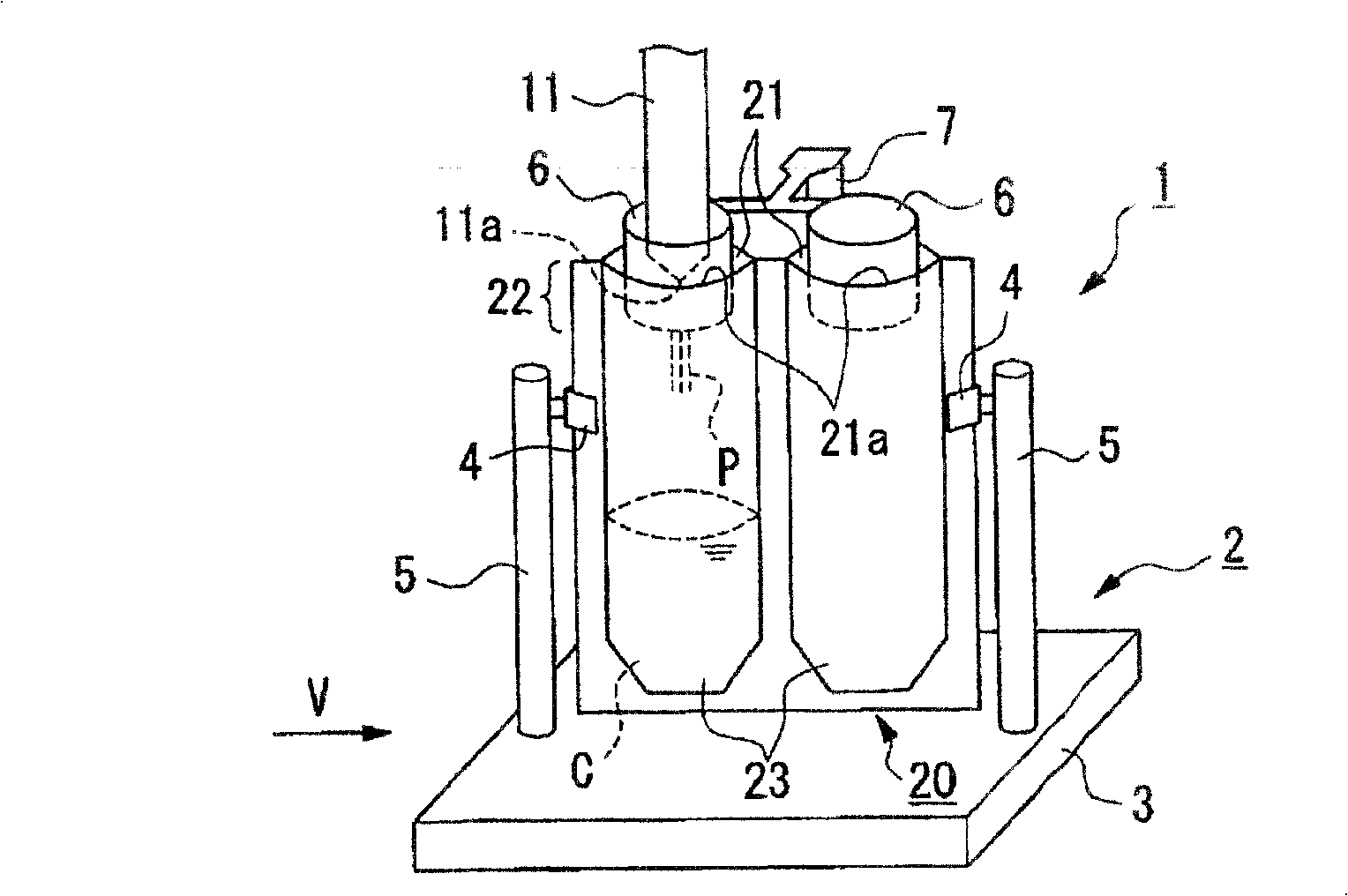

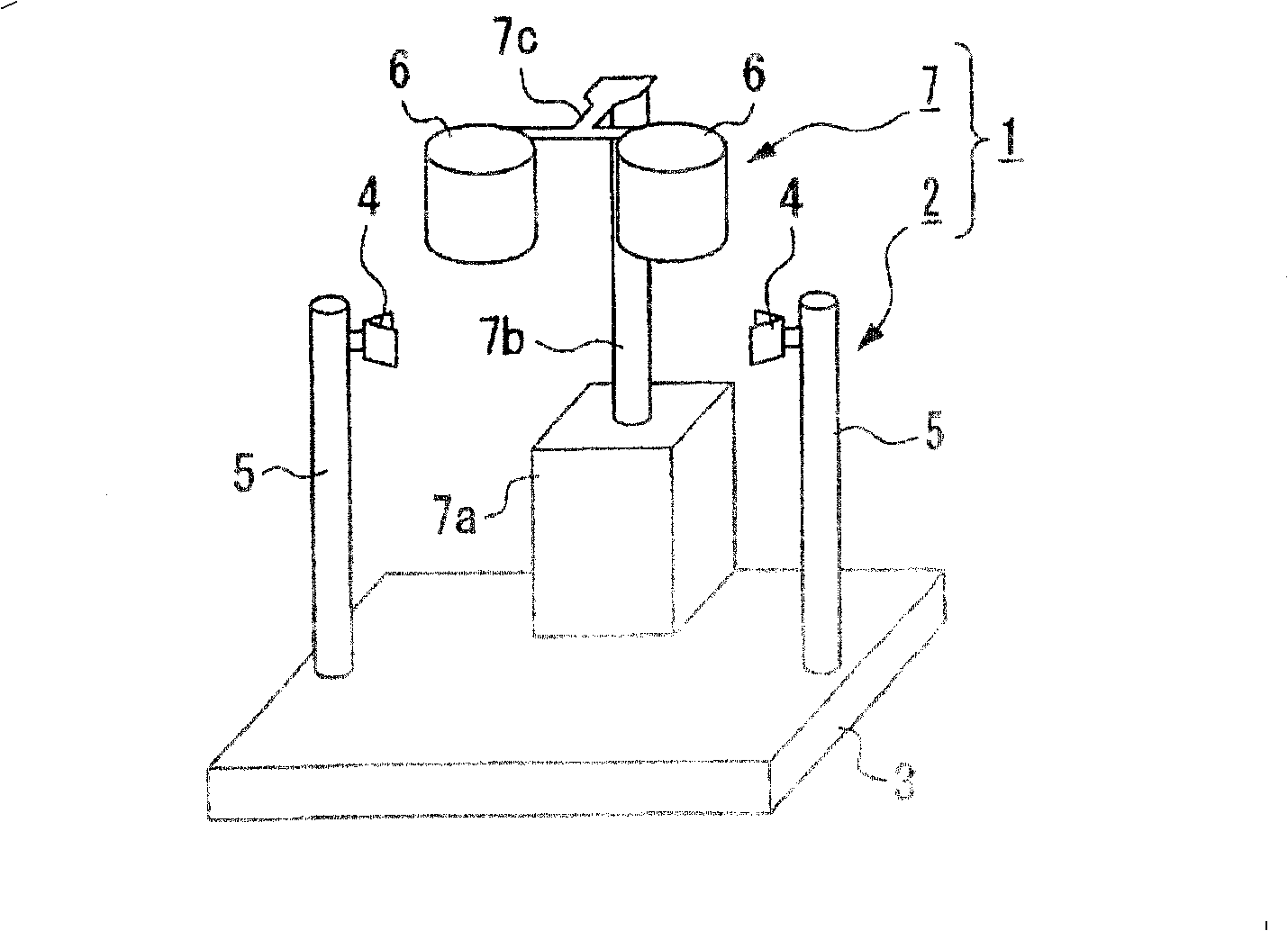

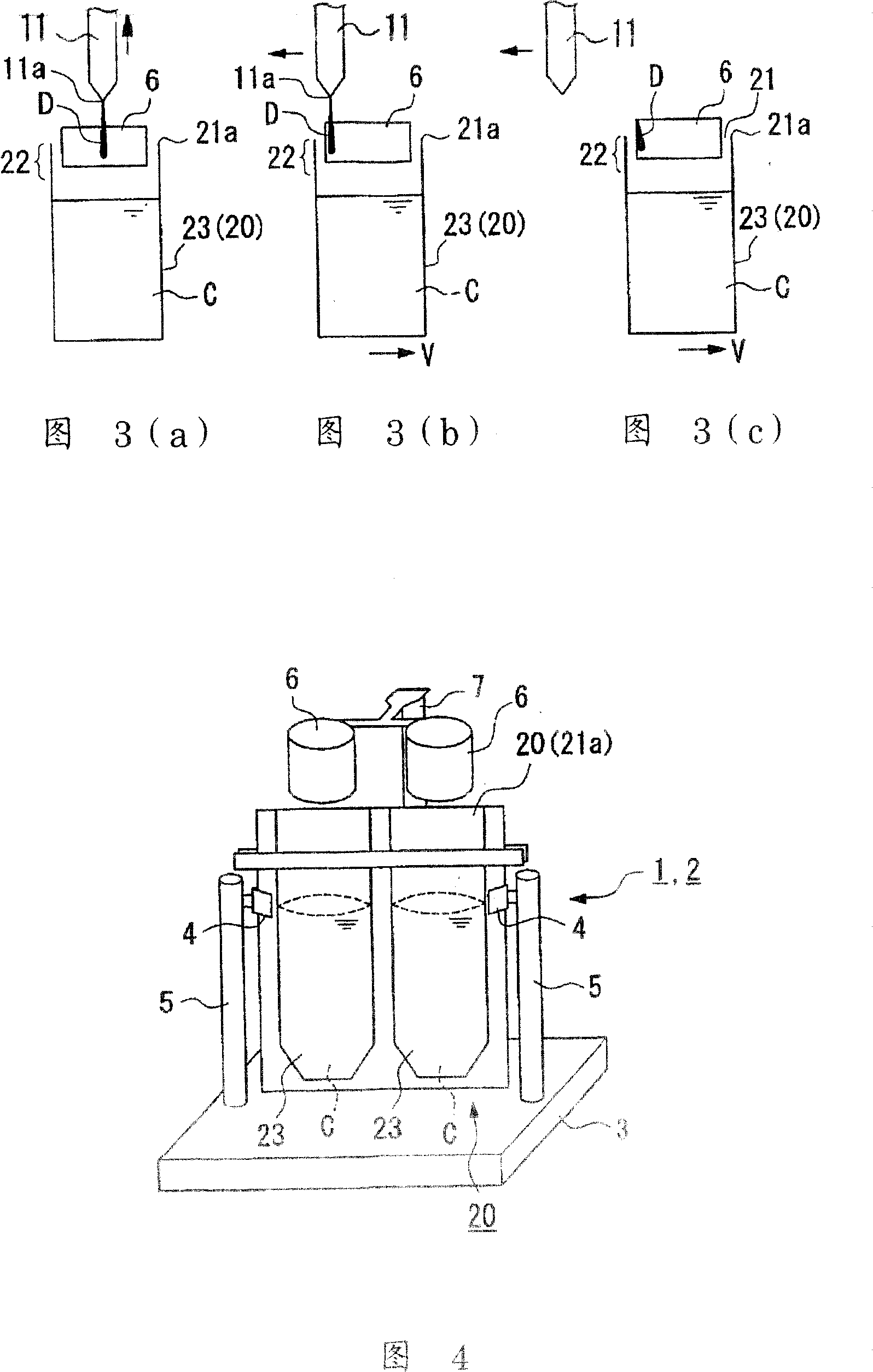

[0036]Hereinafter, the filling device of the present invention will be described in detail based on the embodiments.

[0037] The filling device of this embodiment will have figure 1 ~The bracket 1 shown in Figure 4 is featured. This holder 1 has: a holder main body 2 provided separately from each packaging container 20, which is transported on a predetermined path in the filling device, and holds the packaging container 20; and receives liquid matter falling or drooping from the front end 11a of the nozzle 11. The receiving member 6 of C's liquid sag (pull wire).

[0038] The filling device of the present invention can be used for filling liquid substances in various fields such as food, drink, industrial chemicals, pharmaceuticals, and cosmetics, for example. Here, the packaging container 20 is a bag body having two storage chambers 23 , but the packaging container 20 is not particularly limited. Generally, as the form of the packaging container 20 that can be applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com