Vertical cylinder-installing and cap-mounting machine

A cylinder and cap machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of damage to the seal and thread surface, uneven gap between the guide sleeve and the hydraulic cylinder, oil leakage, etc., to achieve the elimination of hydraulic pressure The effect of cylinder mouth slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

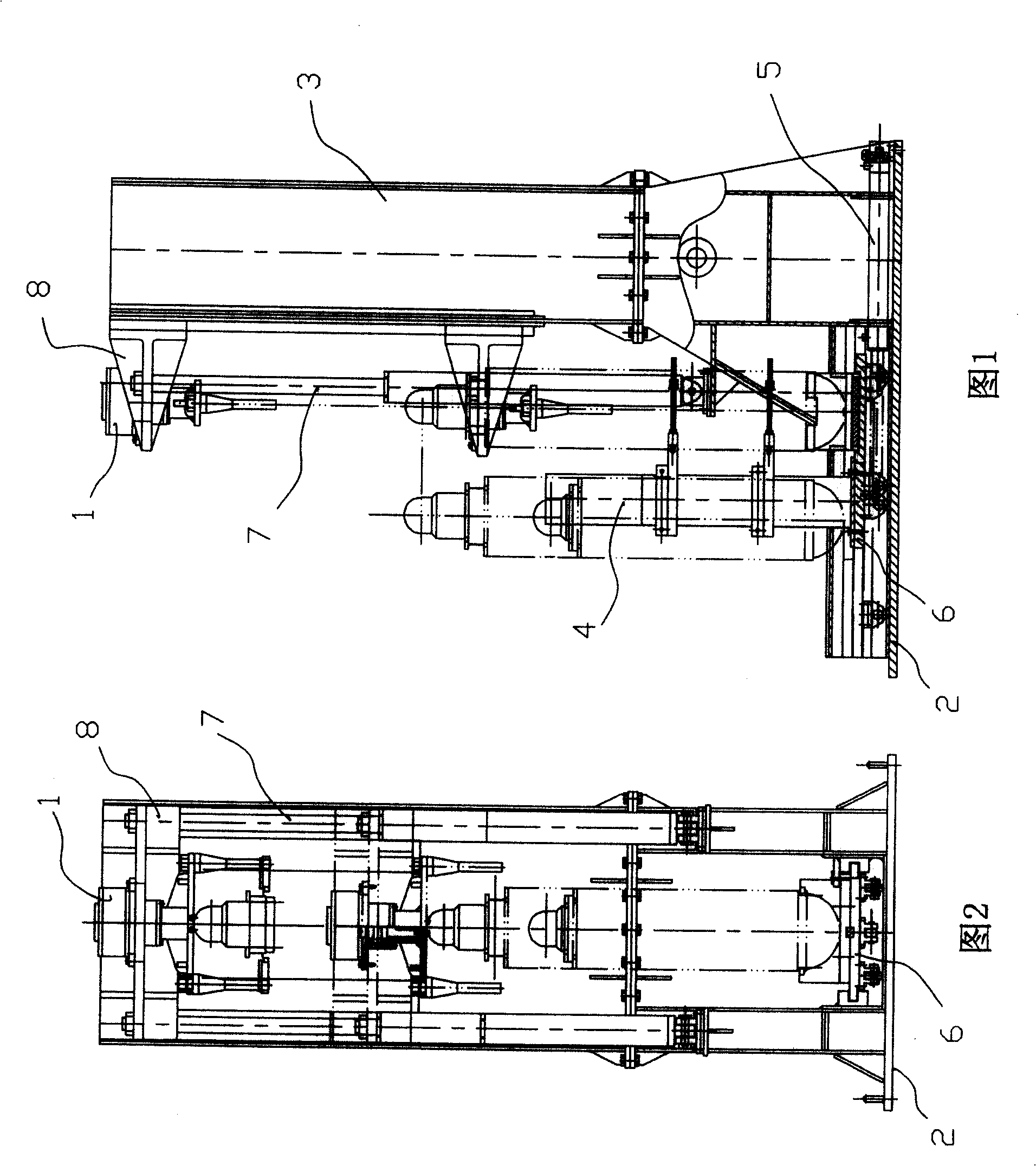

[0010] As shown in the figure, the vertical cylinder capping machine of the present invention includes a frame of an "L" shape formed by a base 2 and a vertical beam 3 vertically arranged thereon, and a capping drive device 1, The horizontal guide rail on the base 2 and the vertical guide rail on the vertical beam 3; the base 2 is provided with a fixed pile 4; the horizontal guide rail is provided with a loading vehicle 6 driven by a horizontal hydraulic jack 5; A slide block 8 driven by a vertical hydraulic jack 7 is arranged on the vertical guide rail, and the upper cap driving device 1 is arranged on the slide block 8 .

[0011] The working principle of the present invention is as follows:

[0012] When the guide sleeve needs to be disassembled, the hydraulic column or jack is vertically hoisted on the loading vehicle 6 by driving or other tools, and the loading vehicle 6 is driven by the horizontal hydraulic jack 5 to move the hydraulic column or jack to the upper cap driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com