Rotary compressor structure with uniform stator and rotor clearance

A stator-rotor and rotor-type technology, applied in the direction of rotary piston type/swing piston type pump components, mechanical equipment, machines/engines, etc., can solve the impact of compressor performance, the decrease of compressor work efficiency, and the low gap between stator and rotor. Uniformity and other problems to achieve the effect of solving uneven gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

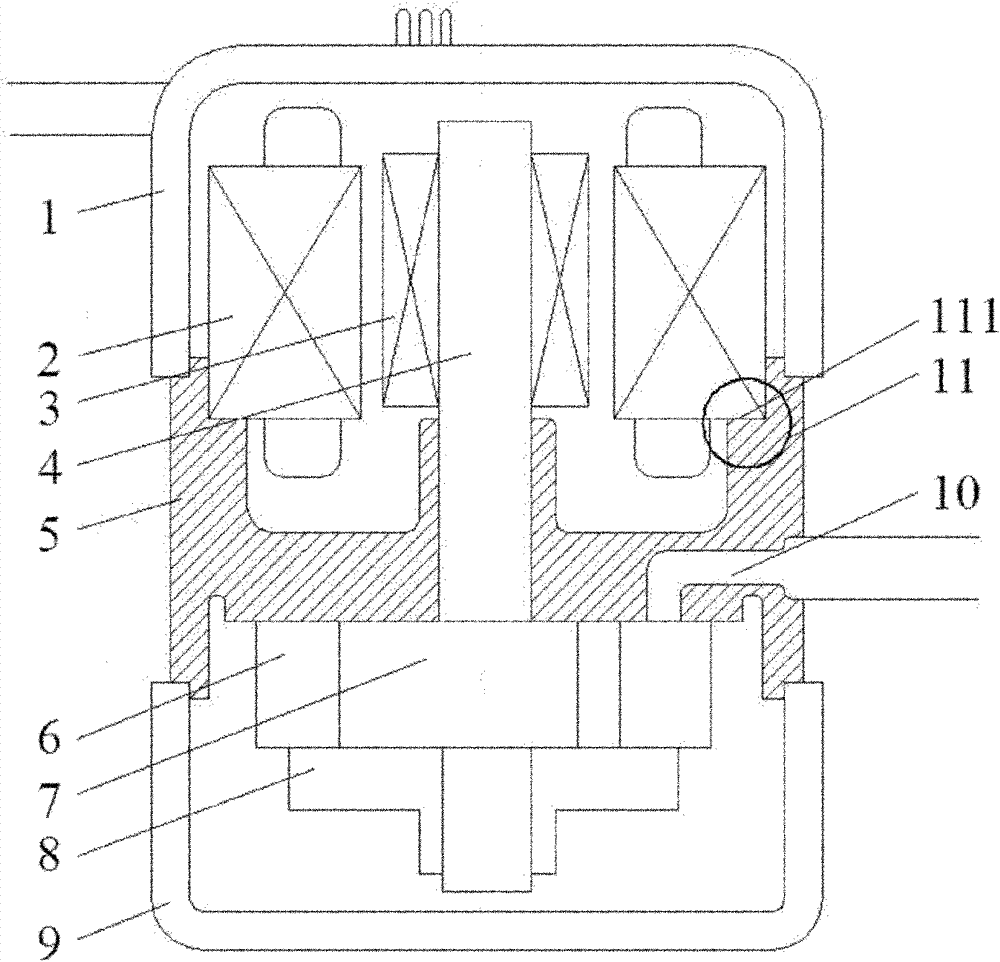

[0017] Such as figure 1 As shown, the structure of the rotor compressor with uniform stator and rotor clearance includes upper casing cover 1, stator 2, rotor 3, crankshaft 4, integrated frame 5, cylinder 6, piston 7, lower cylinder head 8, lower casing The cover 9, the air intake connecting pipe 10, and the integrated frame 5 are formed by one-time casting by metal materials, such as cast iron (FC250). The upper part of the integrated frame 5 is connected and fixed with the upper shell cover 1 by laser welding, and the lower part is connected and fixed with the lower shell cover 9. The top of the integrated frame 5 is provided with an inner concave platform 11, and the inner concave platform 11 An inner concave platform plane 111 is provided, and the lower end of the stator 2 is fixedly connected to the inner concave platform plane 111 by bolts.

[0018] Due to the integrated processing of the upper cylinder head and the housing, the two are combined into an integrated frame...

Embodiment 2

[0020] see figure 1 , a rotor-type compressor structure with a uniform stator-rotor gap, wherein the upper part of the integrated frame 5 is connected and fixed with the upper casing cover 1 by adhesive, and its lower part is connected and fixed with the lower casing cover 9 by adhesive, and the lower end of the stator 2 The adhesive connection is fixed on the inner concave platform plane 111, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com