Photovoltaic module and production method thereof

A technology for photovoltaic modules and photovoltaic cells, which is applied in photovoltaic power generation, circuits, electrical components, etc., and can solve problems such as damage to batteries and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

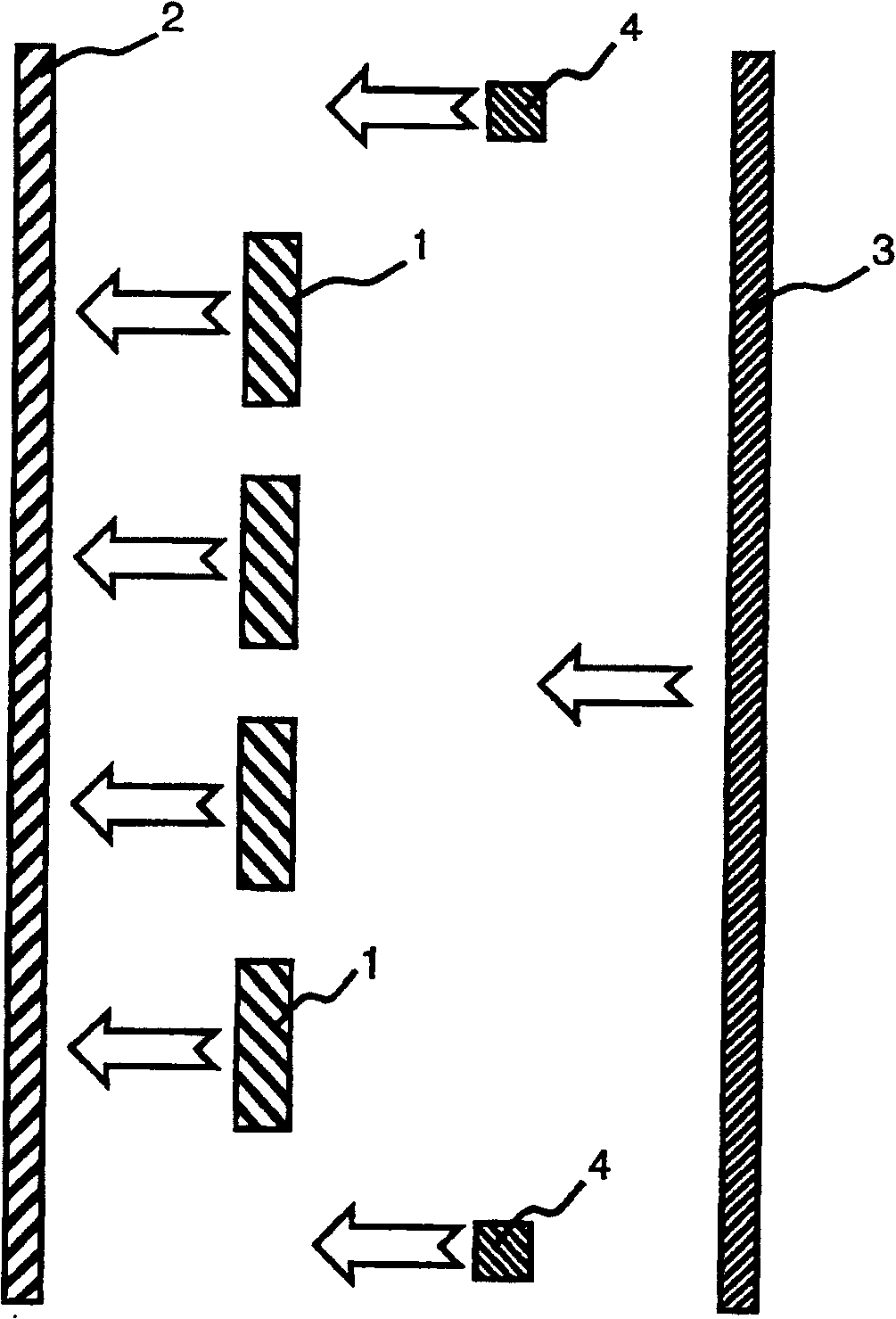

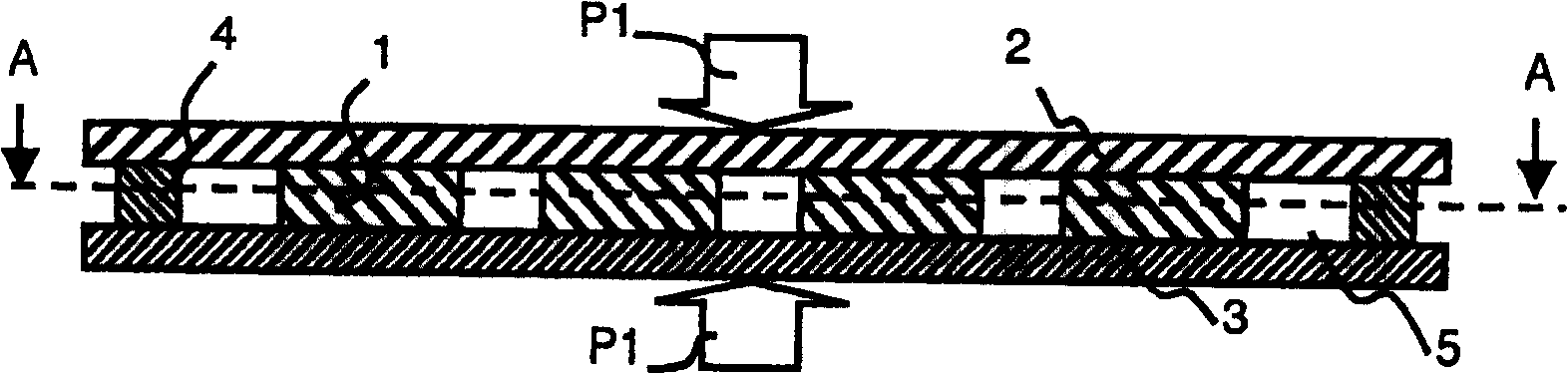

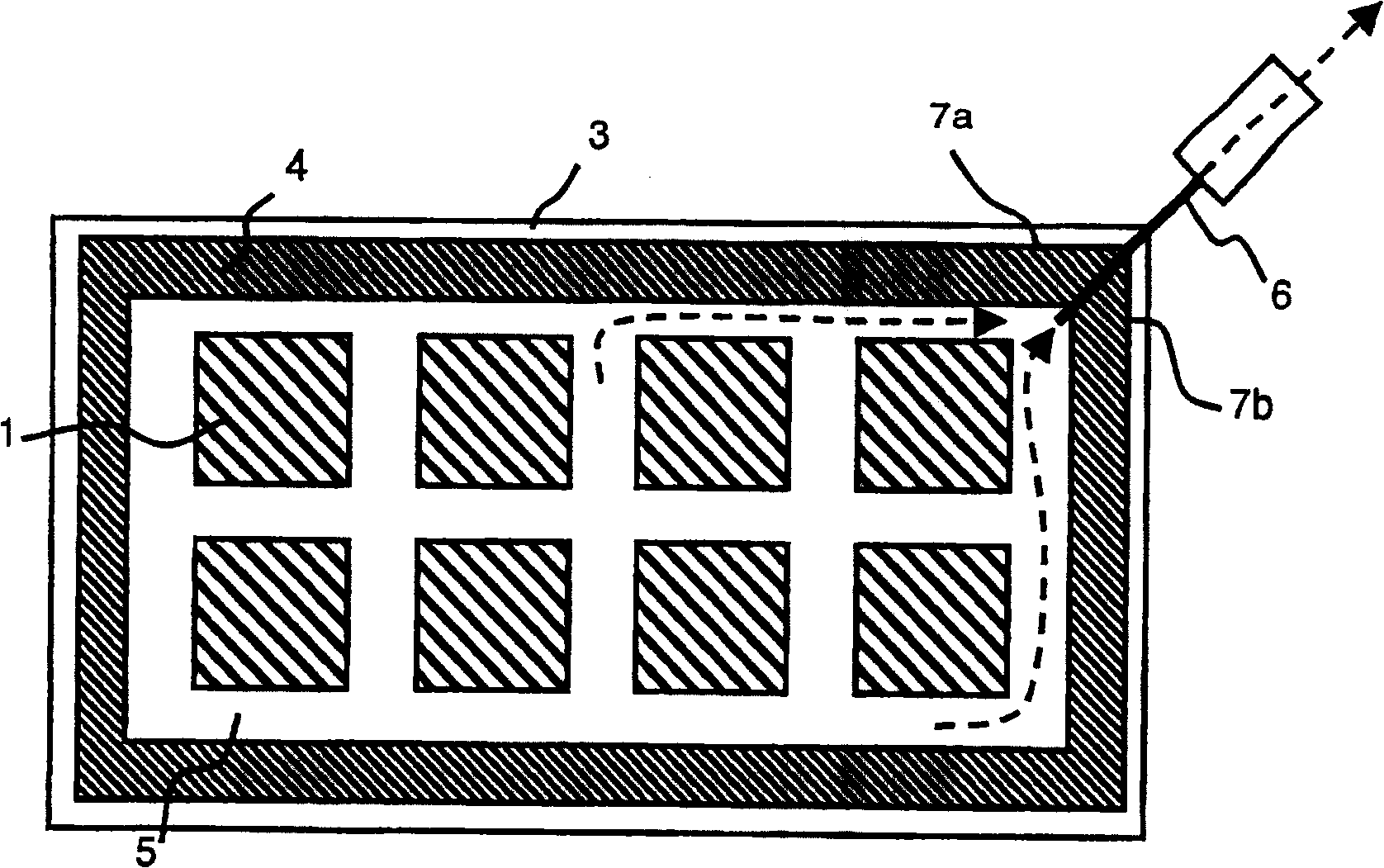

[0021] figure 1 The assembly of a photovoltaic cell 1 and an organic seal 4 arranged side by side between a front sheet 2 and a back sheet 3 is shown. For assembly, plates 2 and 3 and photovoltaic cell 1 are kept parallel to each other. In order to protect the photovoltaic cell 1 during assembly, the cell may be pre-fixed on one of the plates, for example on the back plate 3 , prior to the assembly of the plates 2 and 3 , as the corresponding electrical interconnection conductors may be. For example, they can be pre-glued by means of solvent-free organic glues, for example by derivatives of the polyvinyl family. The glue can consist of the same material as the organic seal 4 , for example a polybutene derivative. An organic seal 4 may then be deposited on one of the plates 2 and 3 , for example on the front plate 2 , around the set of photovoltaic cells 1 . The front sheet 2 and the back sheet 3 are then sealed by means of an organic seal 4, which may be thermoplastic, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com