Bending apparatus, bending method and curved roller for a glass sheet

A technology for bending and forming glass sheets, applied in glass forming, glass re-forming, glass manufacturing equipment, etc., can solve the problems of difficult strengthening treatment, heat loss, time required, etc., and achieve excellent appearance design, shape accuracy and strengthening. Excellent effect of the degree of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The ideal embodiment of the glass plate bending forming device of the present invention will be described in detail below with reference to the accompanying drawings.

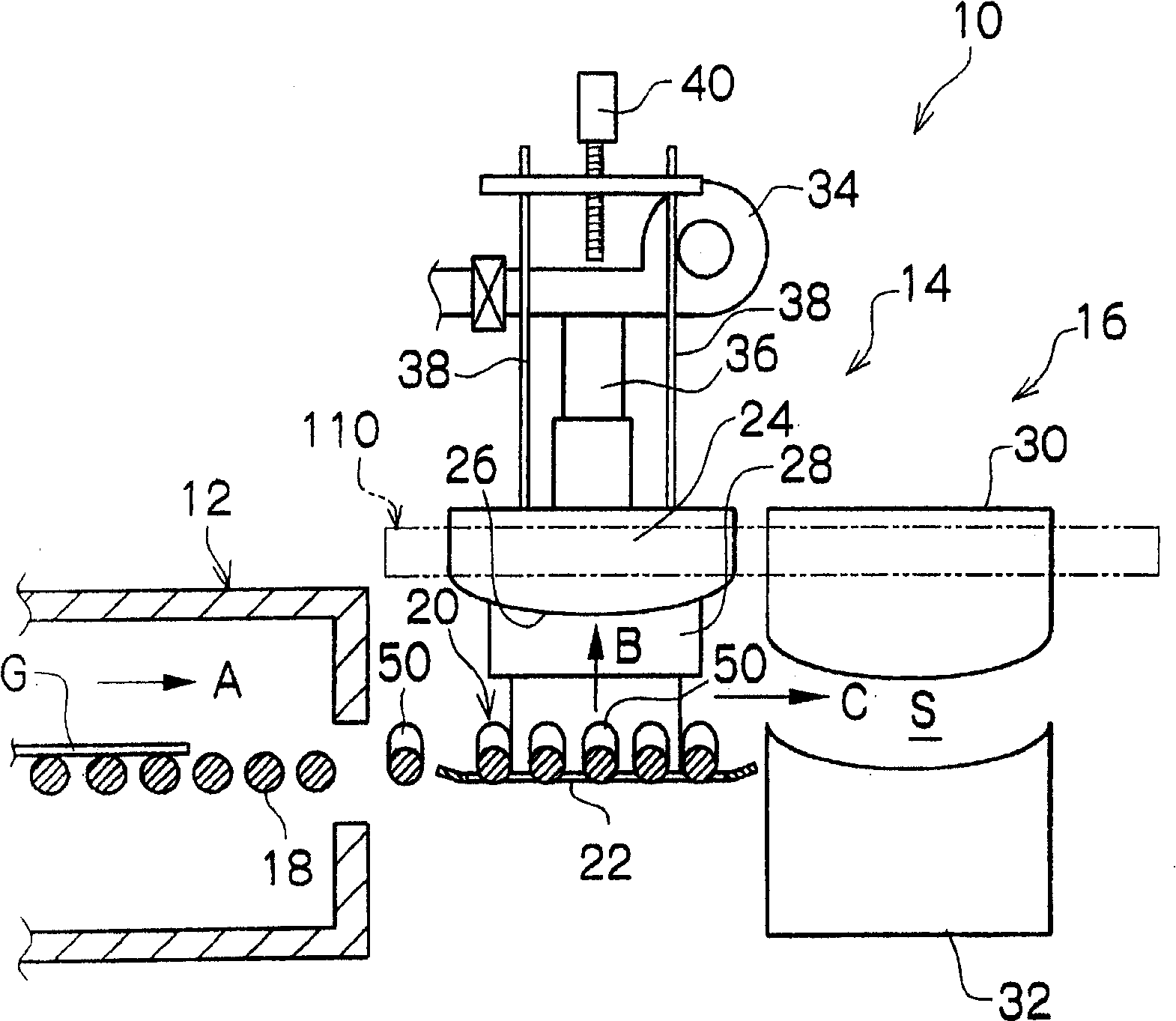

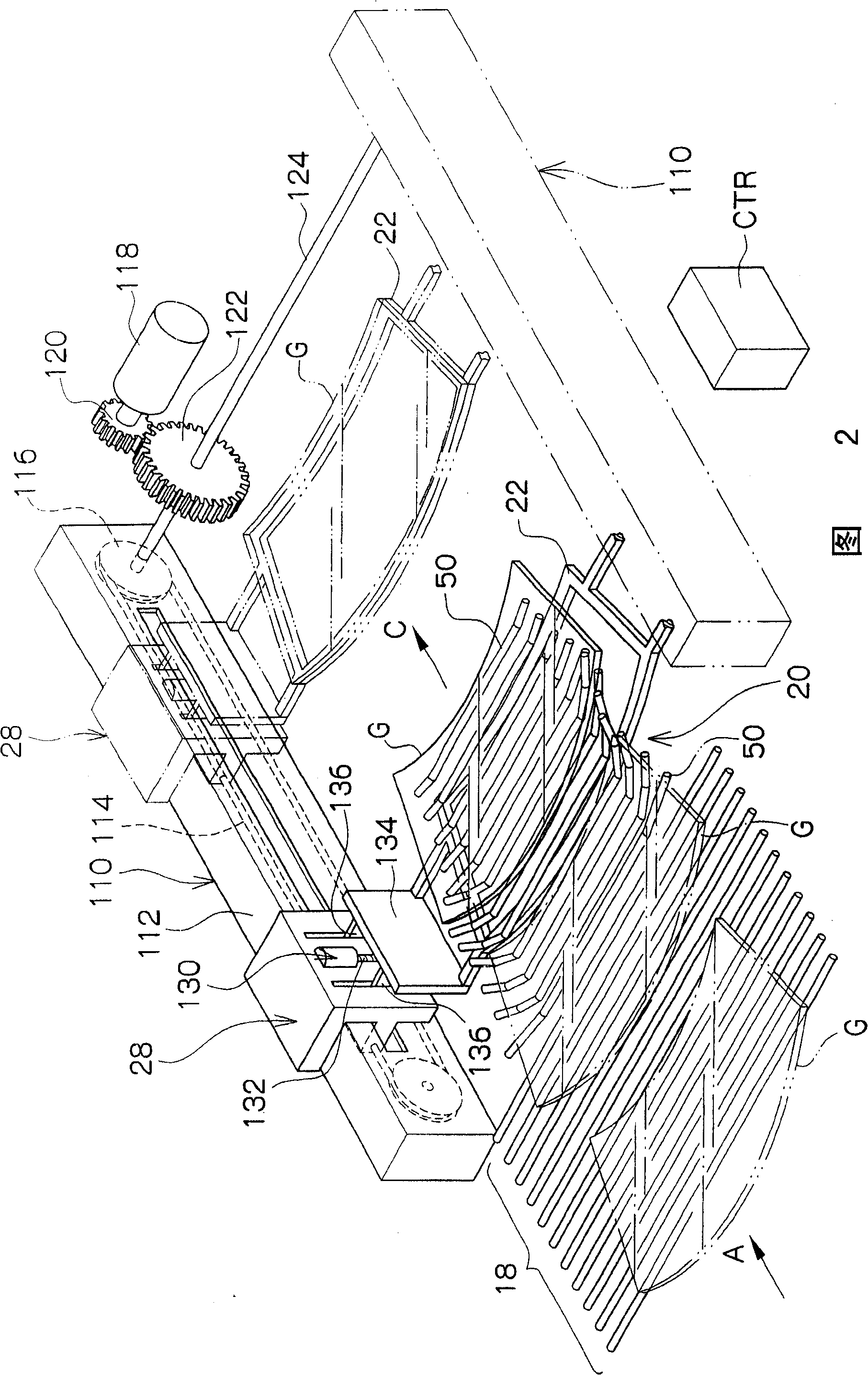

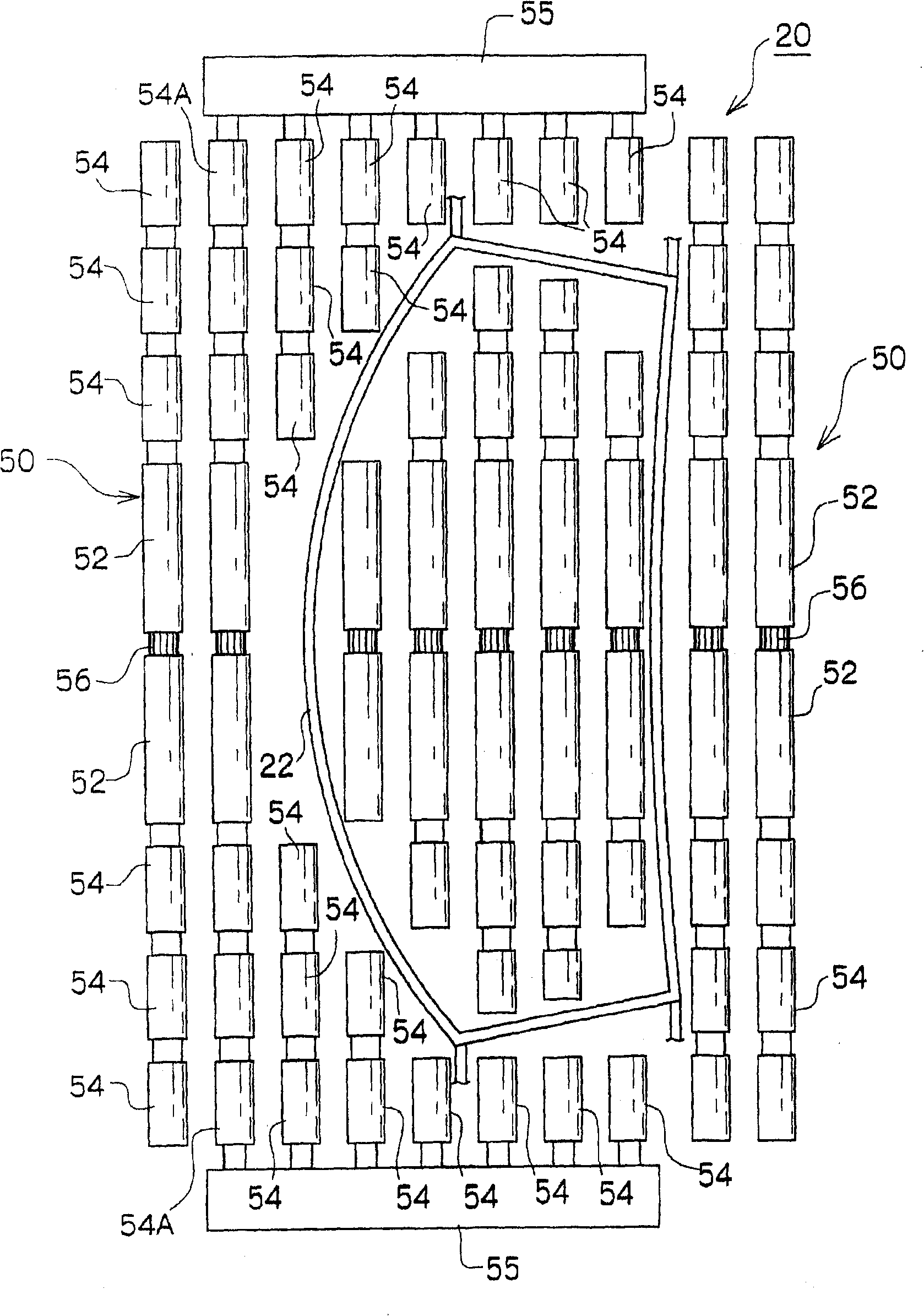

[0036] figure 1 The shown glass plate bending and forming device 10 is a rear glass manufacturing device for automobiles, and is composed of a heating furnace 12, a forming device 14, and an air cooling and tempering device 16 arranged in sequence from the upstream side to the downstream side along the conveying direction of the glass plate G. . In addition, the operations of various parts of the bending forming device 10 are collectively controlled by the controller CTR in FIG. 2 .

[0037] The heating furnace 12 is provided with a roller conveyor belt 18 composed of a plurality of straight rod-shaped silica rollers. The flat glass plate G before bending is passed through the roller conveyor belt 18 figure 1 The direction shown by the arrow A is carried into the heating furnace 12, and is heated to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com