Plant builder system with integrated simulation and control system configuration

A builder and factory technology, applied in the direction of general control system, control/regulation system, program control, etc., to achieve the effect of promoting design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

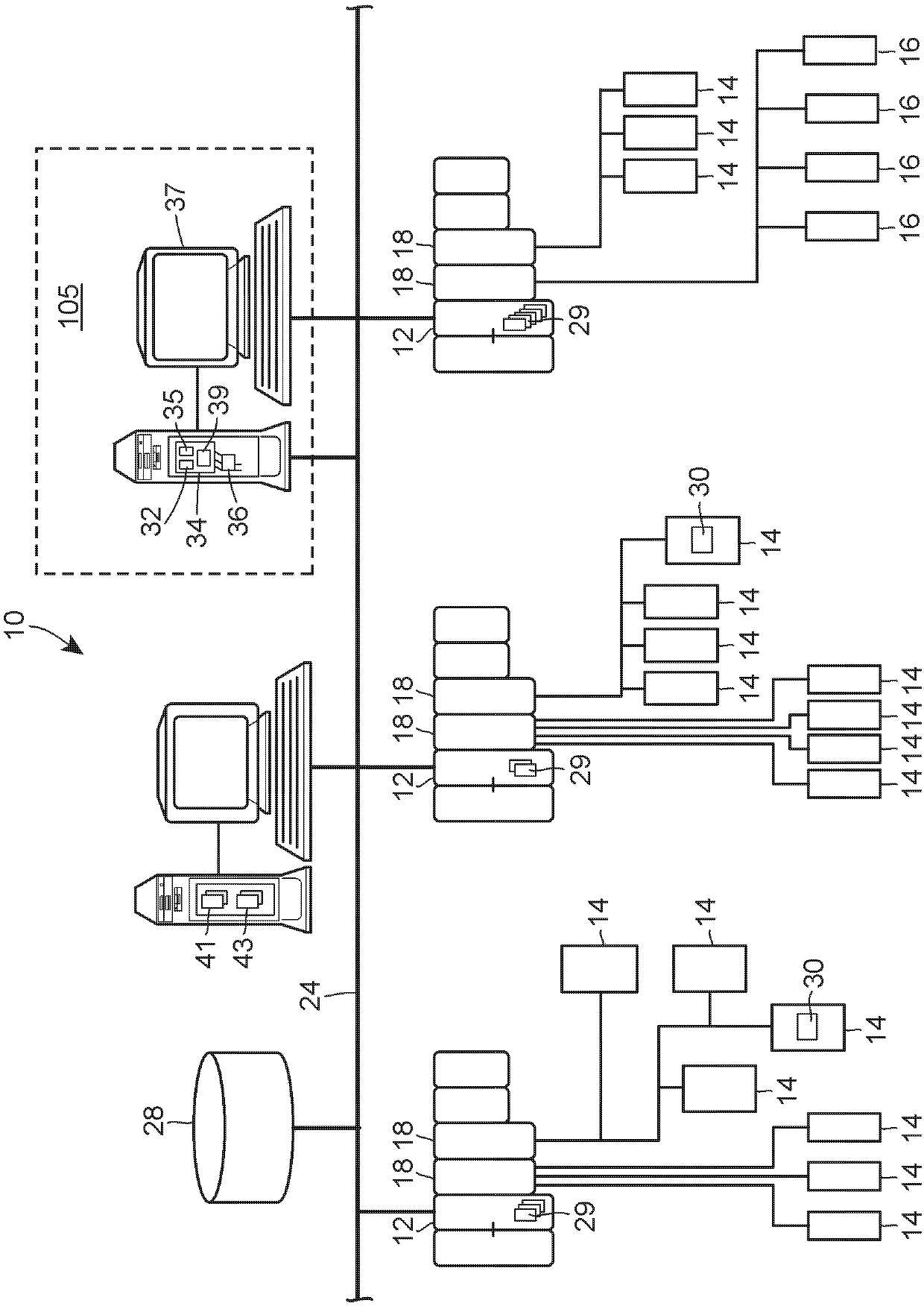

[0020] Refer to Figure 1- Figure 7 Various techniques, systems and methods are discussed. The following description is divided into the following sections:

[0021] I. Overview

[0022] II. Factory

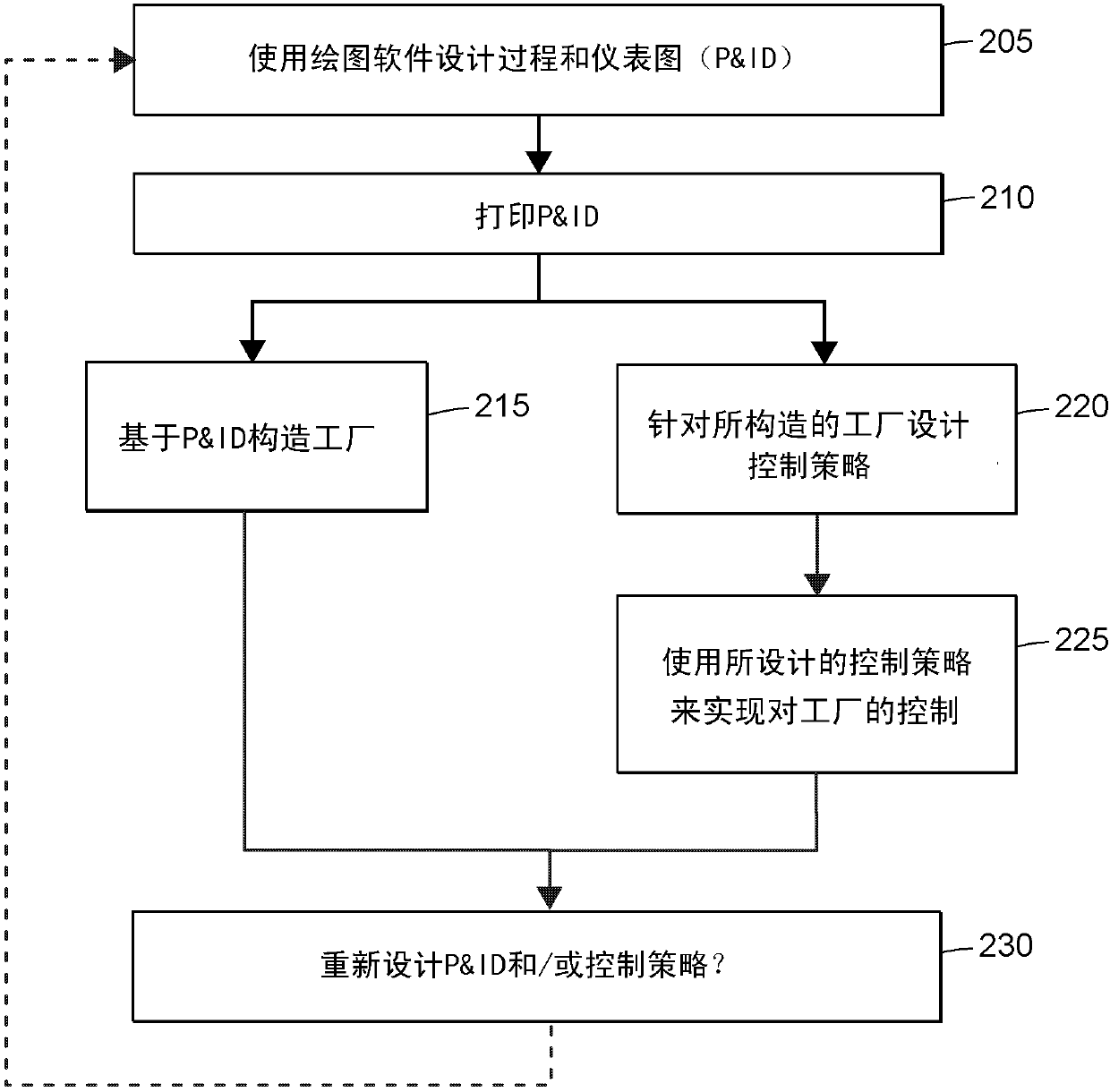

[0023] III. Plant design method of prior art

[0024] IV. DESIGNING A FACTORY ACCORDING TO THE DISCLOSED EMBODIMENTS

[0025] V. Other matters needing attention.

[0026] I. overview

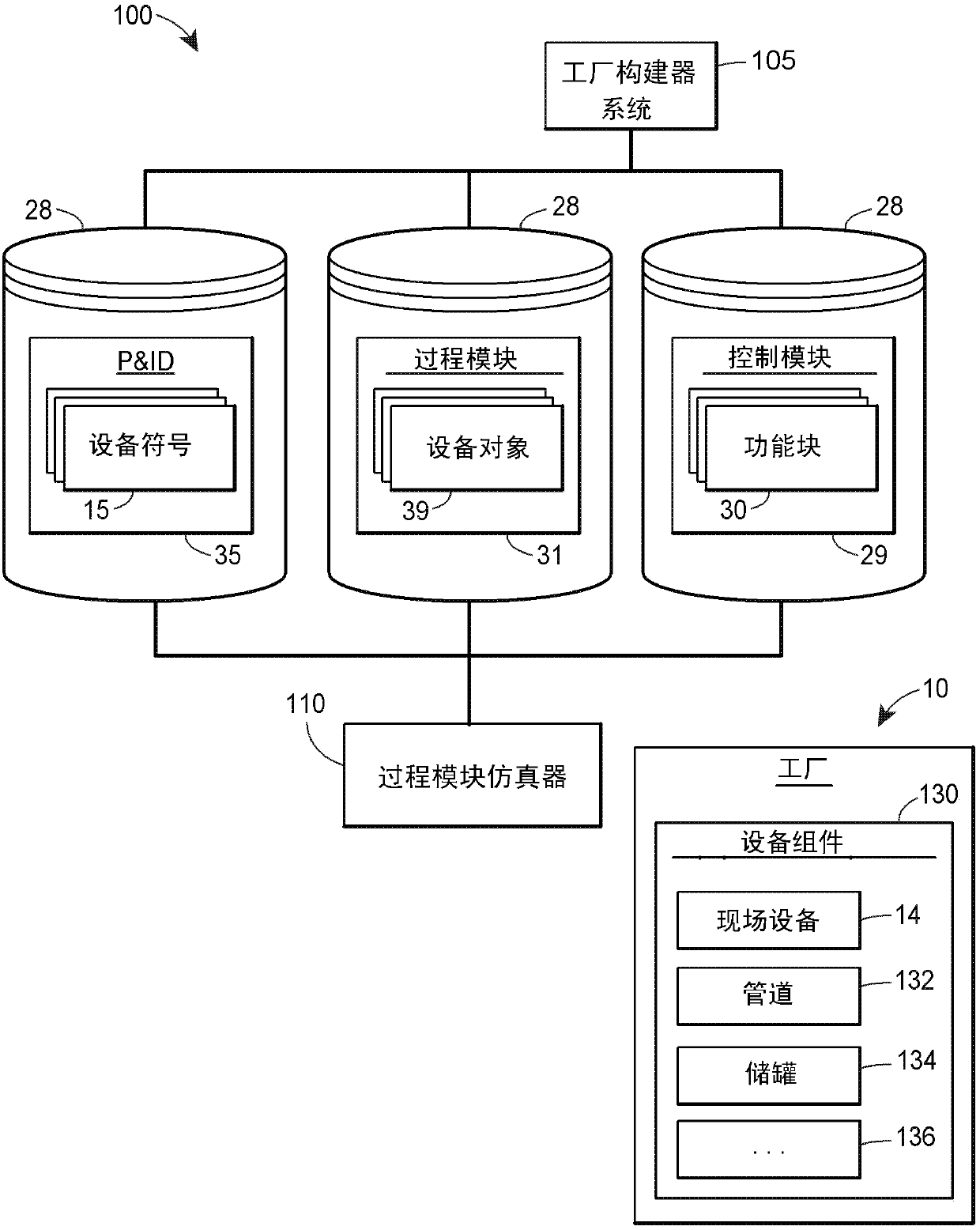

[0027] Figure 1A is a diagram of a system 100 including a plant builder system 105 according to an embodiment. System 100 includes plant builder system 105, one or more databases 28, and / or process module simulator 110. The one or more databases 28 may include piping and instrumentation diagrams (P&IDs) 35, sometimes referred to as process and instrumentation diagrams 35; process modules 31; and / or control modules 29.

[0028] In general, plant builder system 105 (sometimes referred to as plant builder 105) is a computer or group of computers configured to facilitate the various stages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com