Air thermal energy heat pump type steam boiler

A technology of steam boiler and air heat energy, which is applied in the direction of heating method, steam generation method using heat carrier, shielding with air flow, etc. It can solve the problems that hot water boilers cannot provide, steam limits the application range, etc., and achieve energy value improvement , expand the scope of application, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

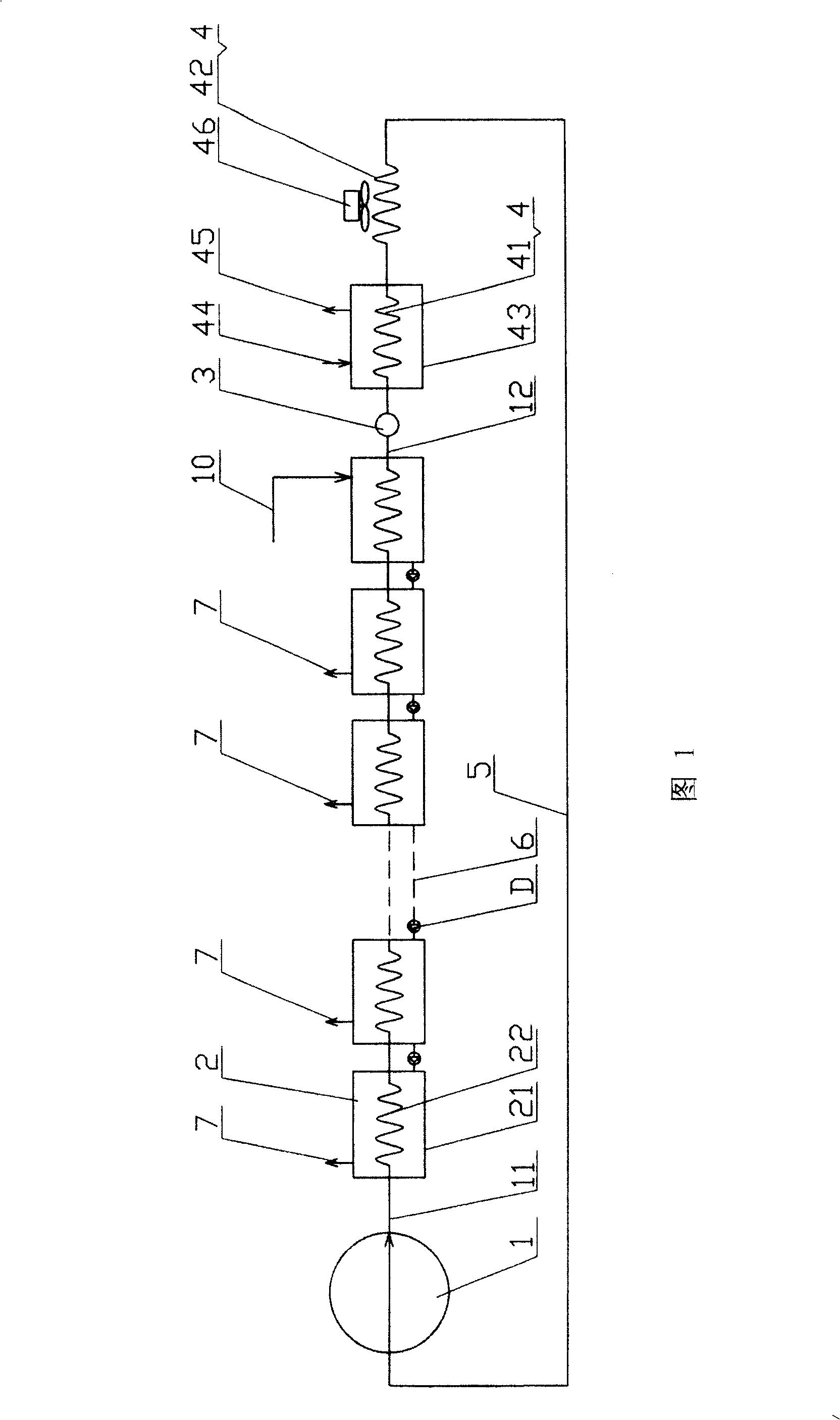

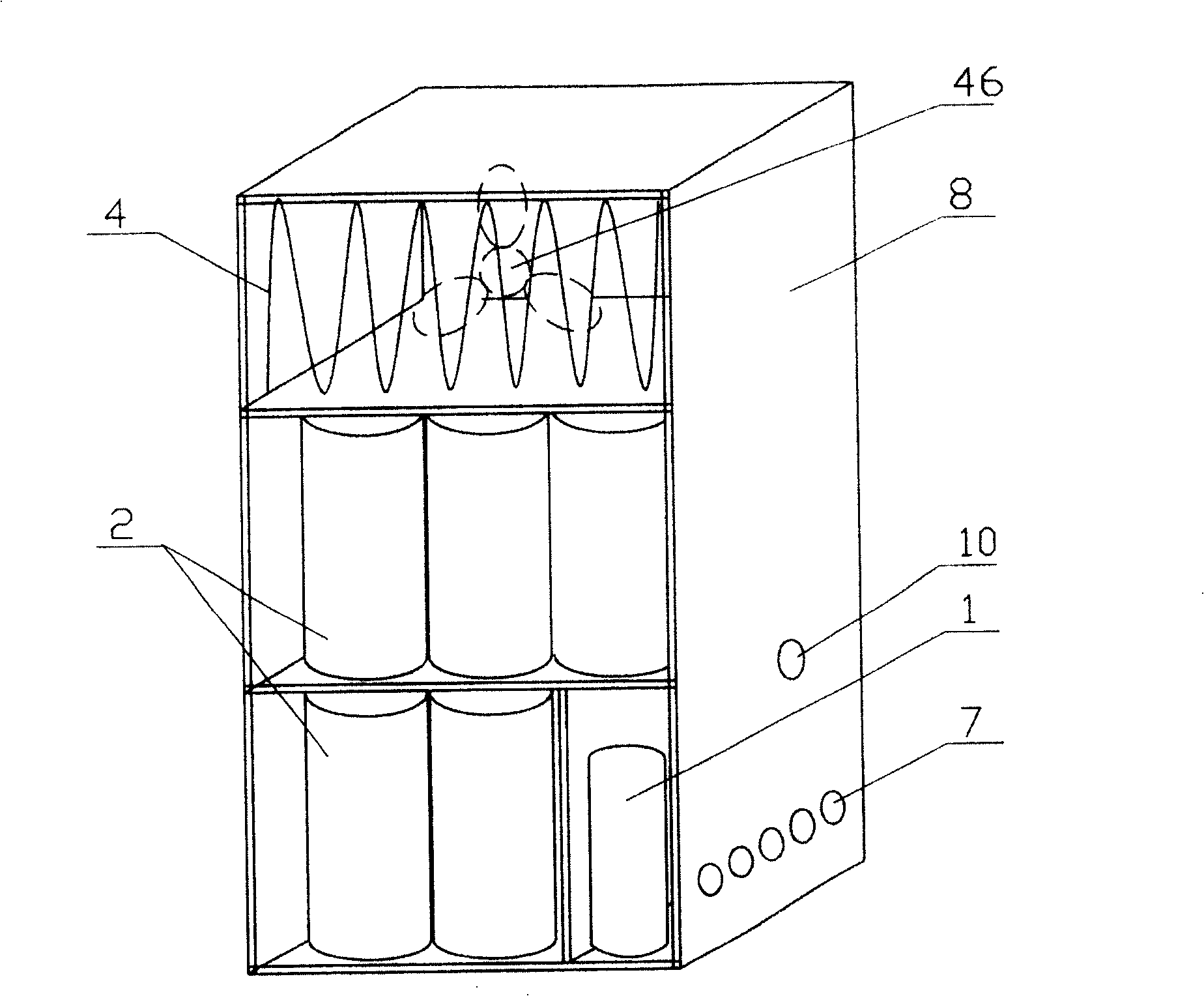

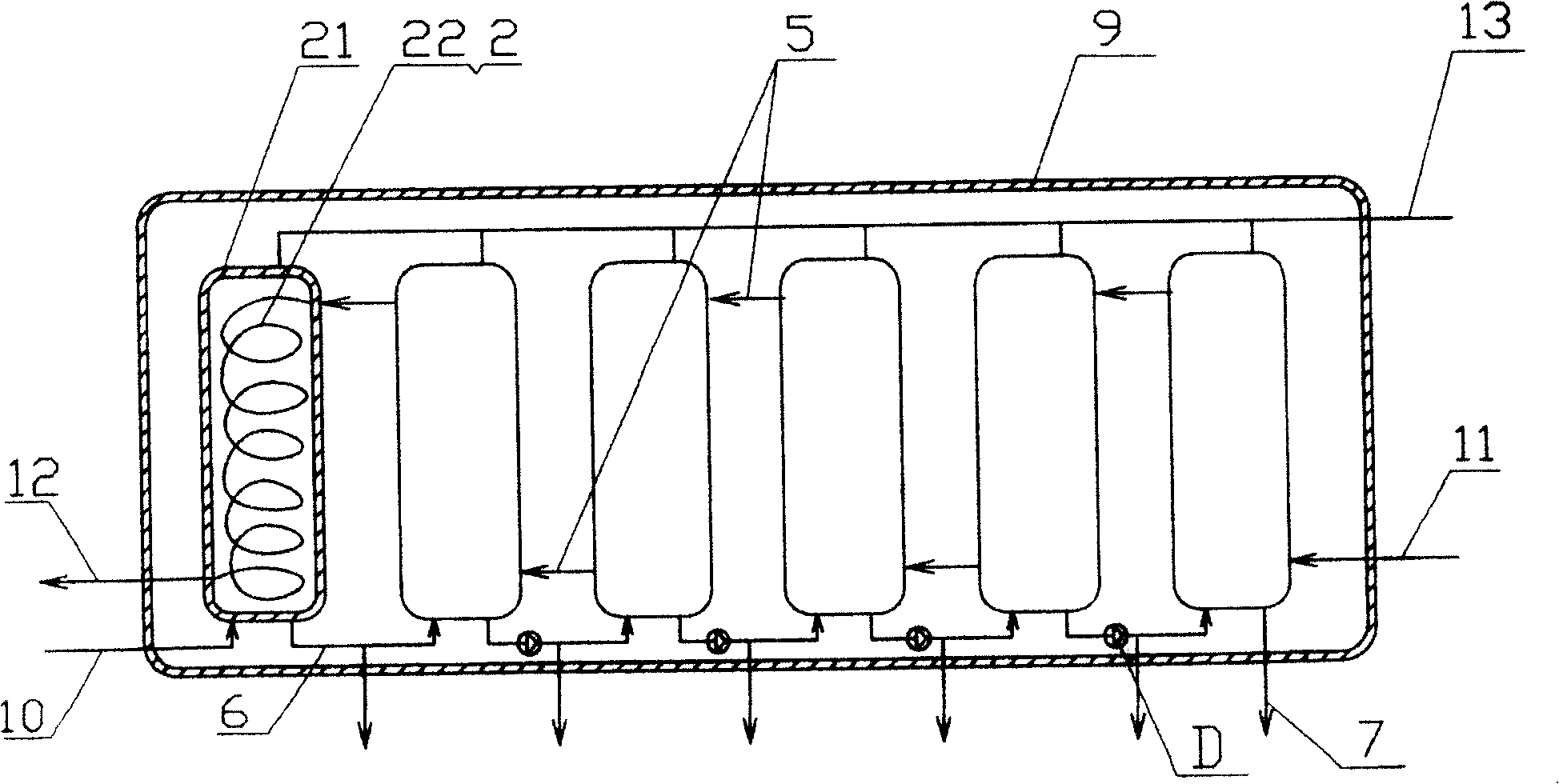

[0018] See Figure 1~ image 3 , the present invention includes a compressor 1, a plurality of condensers 2, a throttle valve 3 and an evaporator 4 connected in sequence, each condenser 2 is composed of a water tank 21 and a radiator 22 inside thereof, and the plurality of condensers 2 The radiators 22 are connected in series through refrigerant pipelines 5 , and each water tank 21 is provided with a waterway interface 6 and a water outlet 7 . The waterway interfaces 6 of this embodiment are connected in series, and the first condenser water tank 21 at the right end is connected with a water inlet 10 for connecting with a water source. On the waterway interface 6 between all or several adjacent water tanks on the left end, there is a one-way valve D in series, and hot water or steam of different temperatures can be obtained at the water outlet 7 of each water tank 21 .

[0019] The evaporator 4 of this embodiment includes an indirect cooling evaporator 41 and a direct cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com