Harmonic gear assembly having active teeth end

A technology of harmonic gears and face gears, applied in gear transmissions, transmissions, belts/chains/gears, etc., can solve the problems of complex force and deformation of the plane flexible wheel, difficult theoretical design and calculation, limited application, etc. Achieve the effect of light weight, wide application prospects and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

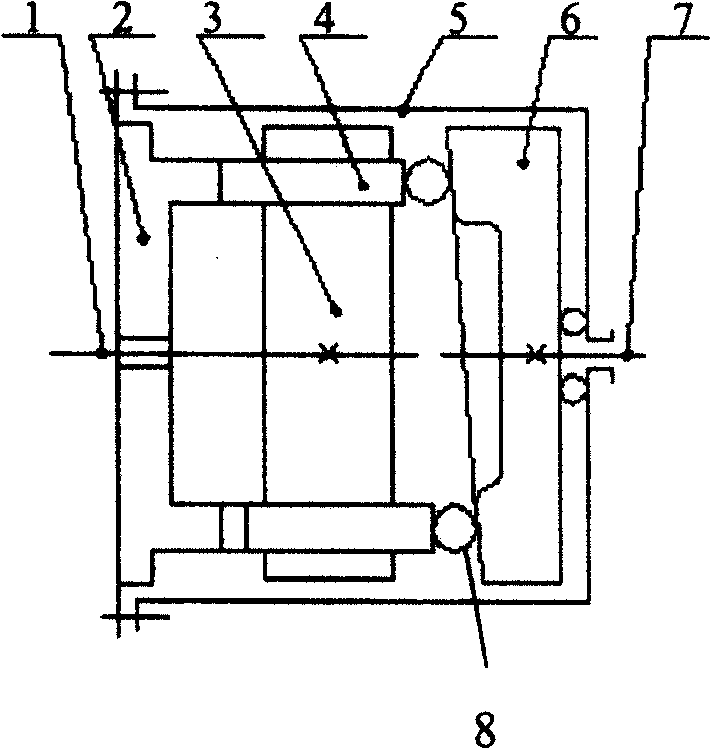

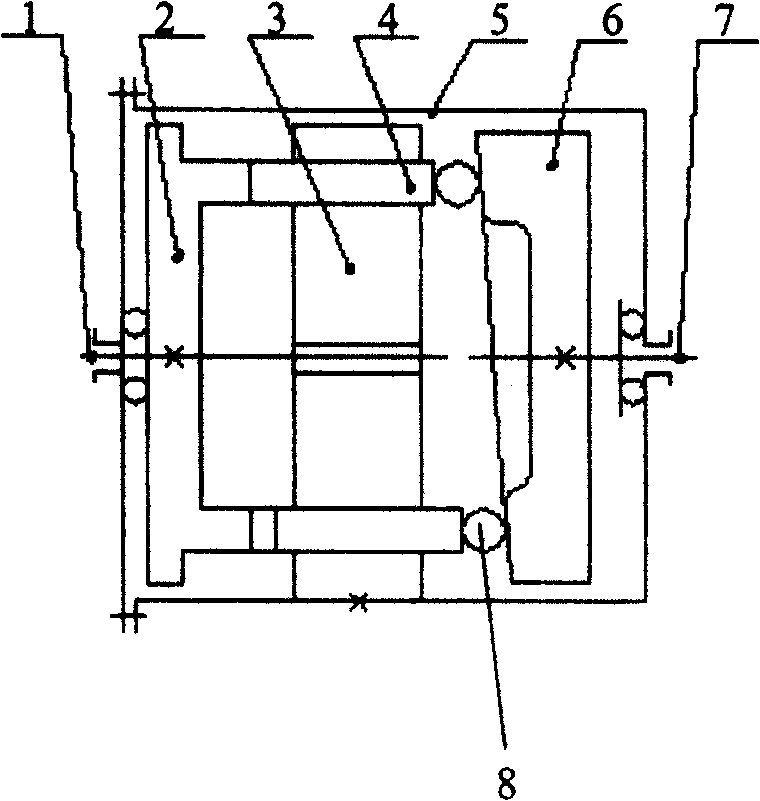

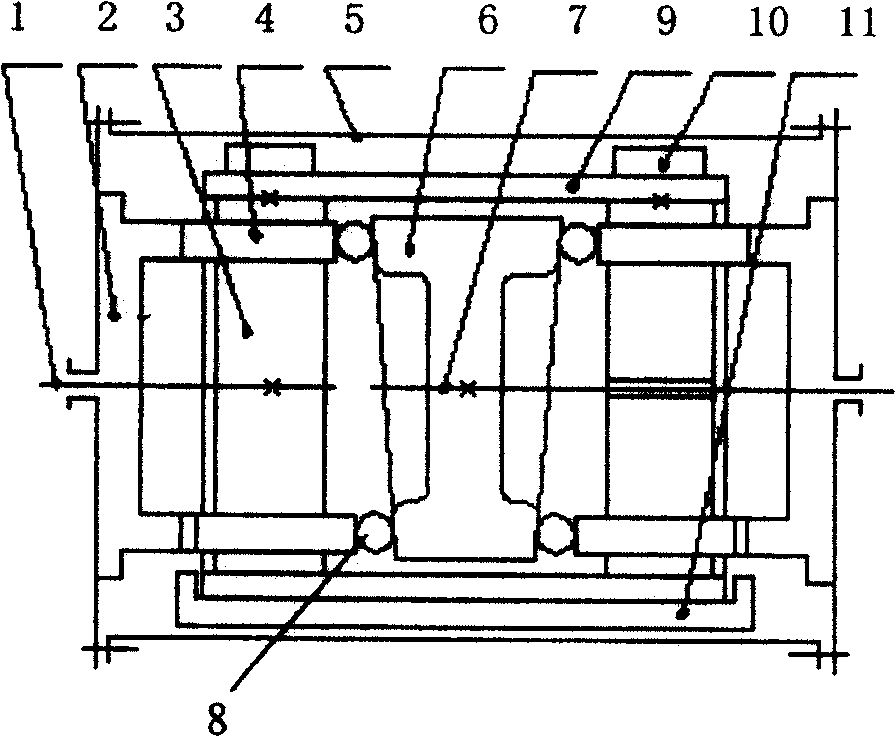

[0019] The present invention is composed of the advantages of the existing face harmonic gear drive and movable tooth drive. It is mainly composed of four basic components such as face gear, wave generator, movable tooth and groove wheel. Single side drive or double side drive type. This new type of movable-tooth end-face harmonic gear transmission belongs to the category of planetary gear trains. Its main structural features are: the rigid wheel in the existing harmonic gear transmission is changed to an end-face gear, and the inner tooth of the rigid wheel is changed to an end-face gear. The gear teeth are evenly distributed along the circumferential direction; the wave generator is changed from a radial disc cam to an axial cylindrical end face cam; the planar flexspline is divided into several movable teeth, and the movable teeth are placed in the groove wheel It can perform axial reciprocating motion. One end of each movable tooth is in contact with the end face cam of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com