Drill pipe twisting device

A technology for drill pipes and translational devices, which is applied in the direction of transmission devices, mechanical control devices, gear transmissions, etc., can solve the problems of large helix angle changes, uneven longitudinal torsion of drill pipes, and low precision, and achieve uniform longitudinal torsion, The effect of compact structure and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

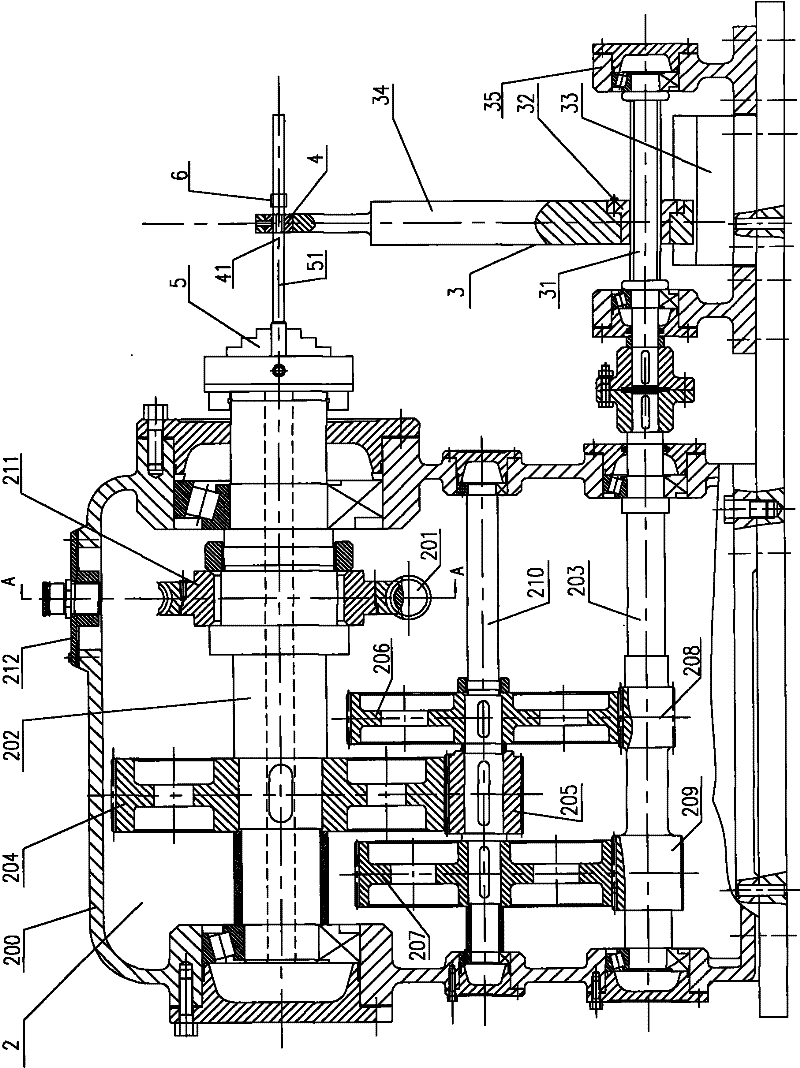

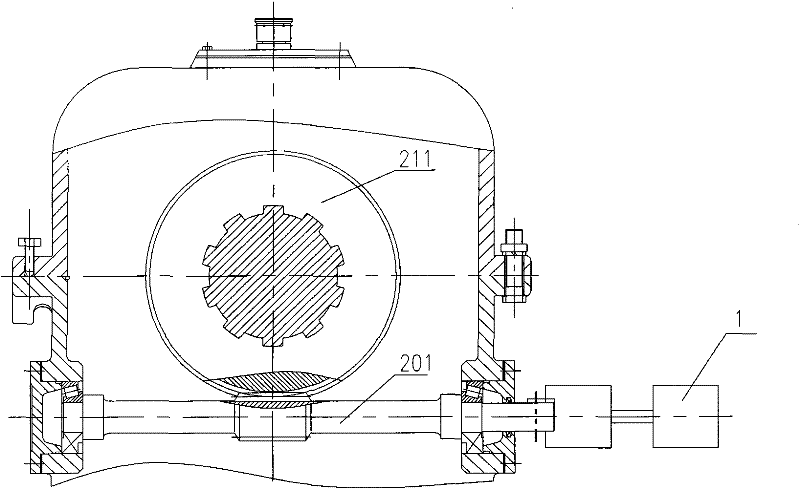

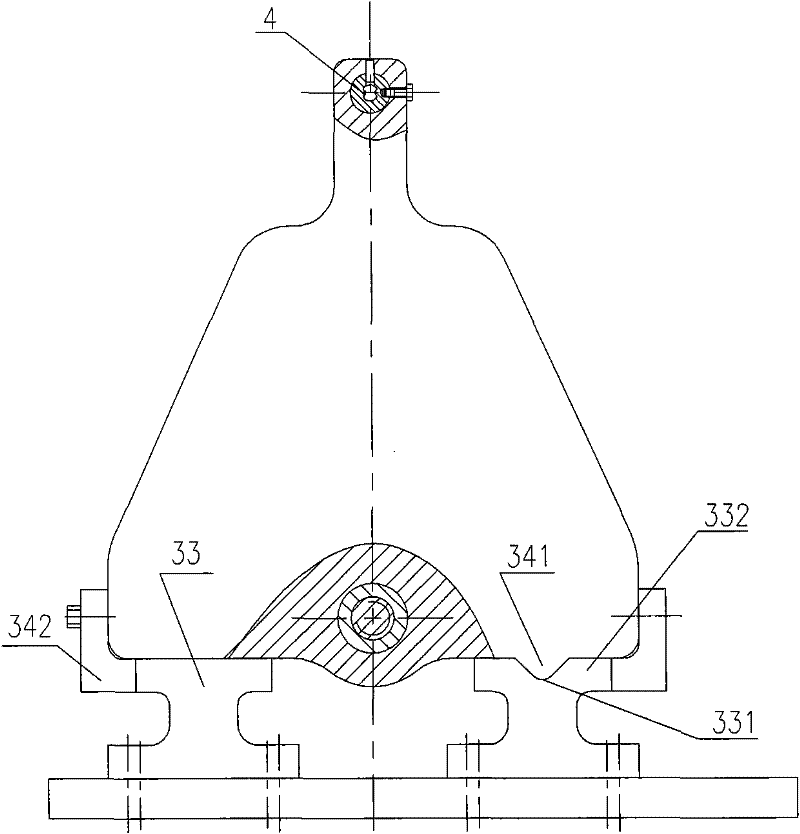

[0033] Such as figure 1 and figure 2 As shown, the drill rod twisting device of the present invention includes a driving motor 1, a transmission device 2, a translation device 3, a screw die 4, a chuck 5 and a heating coil 6, and the transmission device 2 is provided with a worm input shaft 201, a first output shaft 202 and the second output shaft 203. The driving motor 1 is connected to the worm input shaft 201 through a coupling. In this embodiment, in order to make the output speed of the driving motor 1 meet the required requirements, a frequency conversion speed regulation part is installed between the driving motor 1 and the coupling; The chuck 5 is installed on the end of the first output shaft 202, and the chuck 5 is used to clamp the drill pipe and apply torque to one end of the drill pipe; the translation device 3 is connected with the second output shaft 203, and the translation device 3 passes through the second output shaft. The shaft 203 is driven; the screw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com