Friction clutch, particularly for a motor vehicle, comprising differentiated friction means

一种摩擦离合器、离合器的技术,应用在摩擦离合器、机械驱动离合器、离合器等方向,能够解决托板脆弱等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

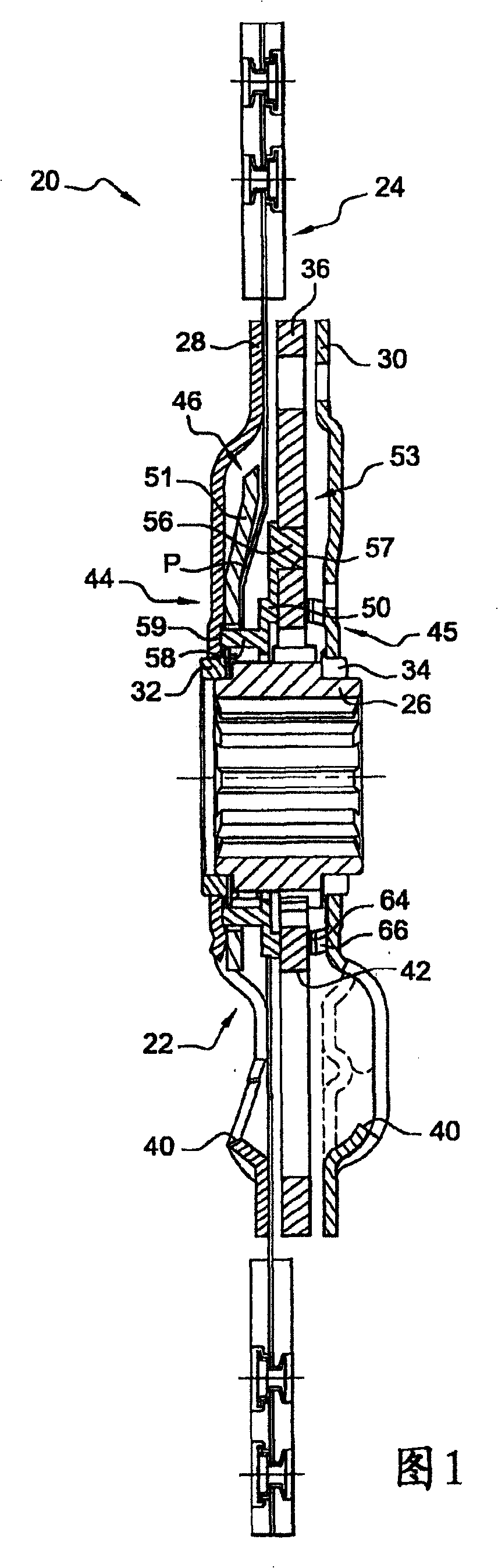

[0053] [53] FIG. 1 shows a friction device of a friction clutch according to a first embodiment of the present invention.

[0054] [54] In the example described, the clutch is used on a motor vehicle to couple a driven shaft, such as the input shaft of a gearbox, with a driven shaft, such as the crankshaft of an internal combustion engine.

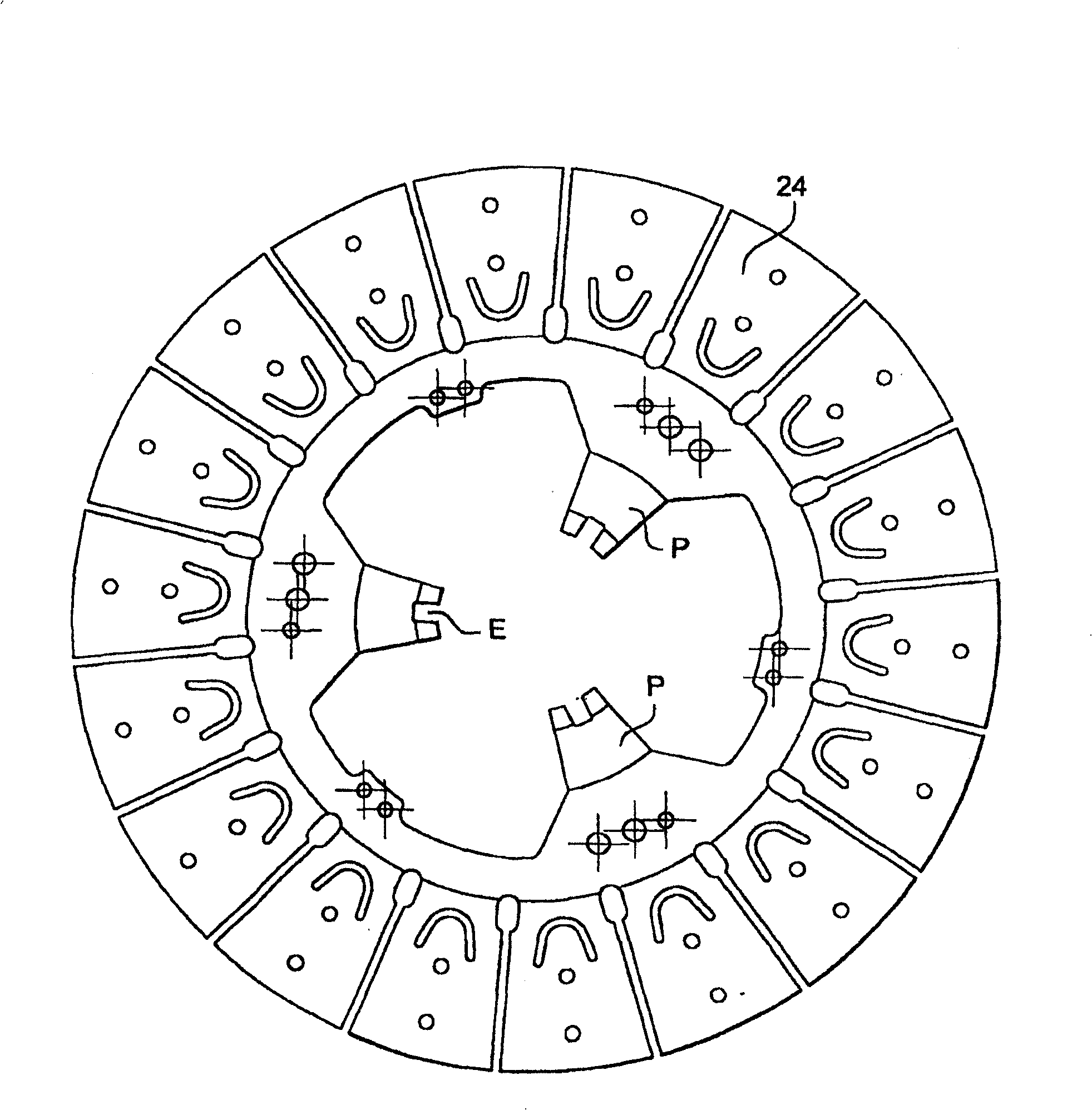

[0055][55] The friction device, generally indicated by the reference numeral 20, has damping means comprising a damper 22. The shock absorber 22 is installed between a rotary input part such as a friction plate 24 and a rotary output part such as a cylindrical bushing 26 coupled to the driven shaft through a longitudinal inner groove provided in the bushing. The input and output parts are substantially coaxial.

[0056] [56] The friction plate 24 is clamped in a known manner between a power flywheel rotatably connected to the drive shaft and a pressure plate driven by the clutch element.

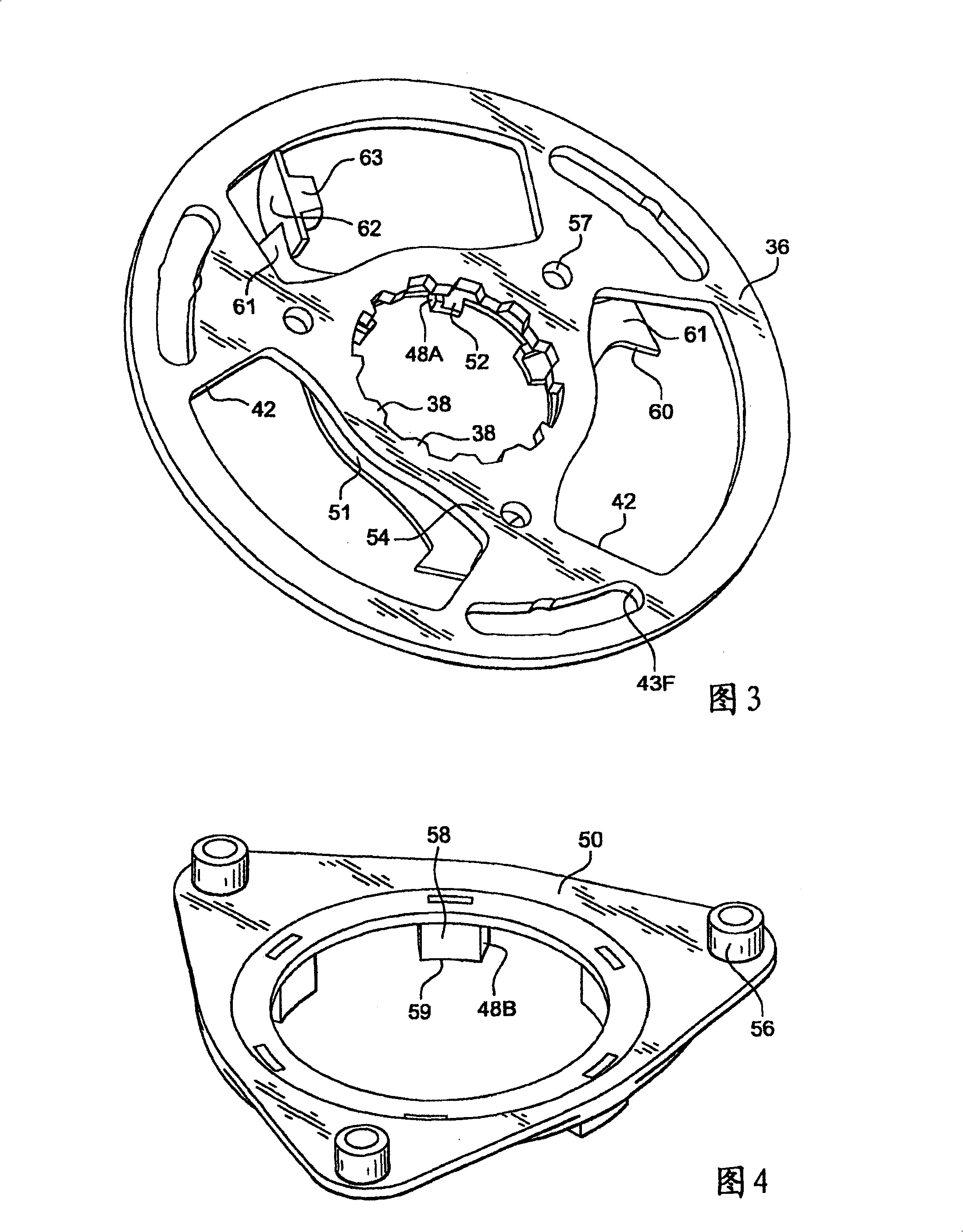

[0057] [57] The shock absorber includes a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com