Glass fiber reinforced macromolecule composite material well cover

A composite material and enhanced technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as cracks, high material brittleness, and unsatisfactory impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

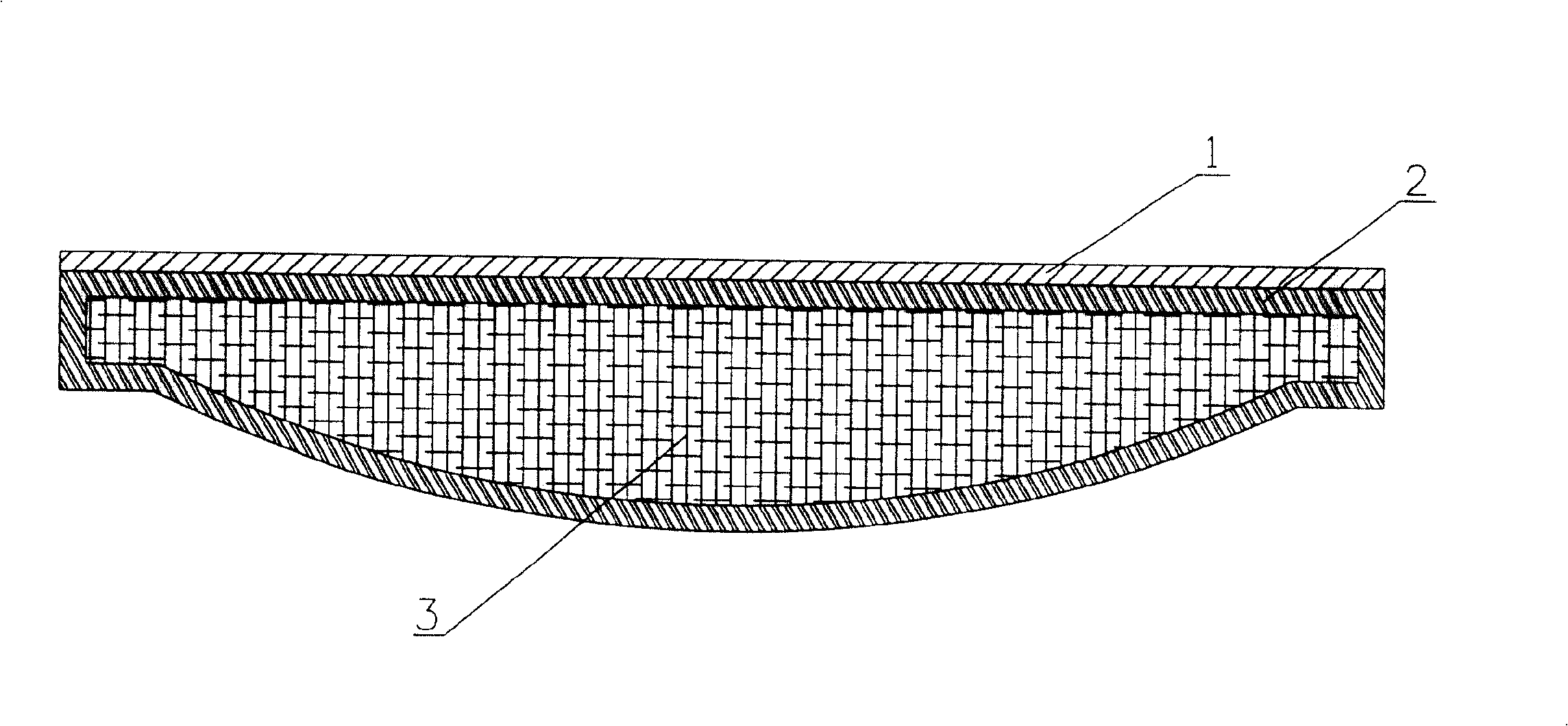

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] The glass fiber reinforced polymer composite manhole cover of the present invention comprises an inner aggregate layer 3 composed of aggregates and functional fillers, an outer reinforced structural layer 2 composed of unsaturated polyester resin and glass fibers, and a wear-resistant layer 1; The outer reinforced structure layer 2 includes unsaturated polyester resin glue A and 3%-15% glass fiber B in a weight ratio of 10%-30%, and the inner core aggregate layer 3 includes aggregate C of 45%-78% and 5%-20% filler D, the wear-resistant layer 1 includes 3%-15% wear-resistant material E.

[0039] Manhole cover is made according to formula of the present invention, operating procedure:

[0040] 15% unsaturated polyester resin glue A, 10% glass fiber B, 60% aggregate C, 12% filler D, 3% wear-resistant material E.

[0041] ① Unsaturated polyester resin glue A is a polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com