Rotatable tool for chip removing machining

A technology of rotating tools and chip machines, applied in the direction of tools for lathes, cutting inserts, manufacturing tools, etc., can solve the problem of the possibility of difficult to accurately center the removable top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

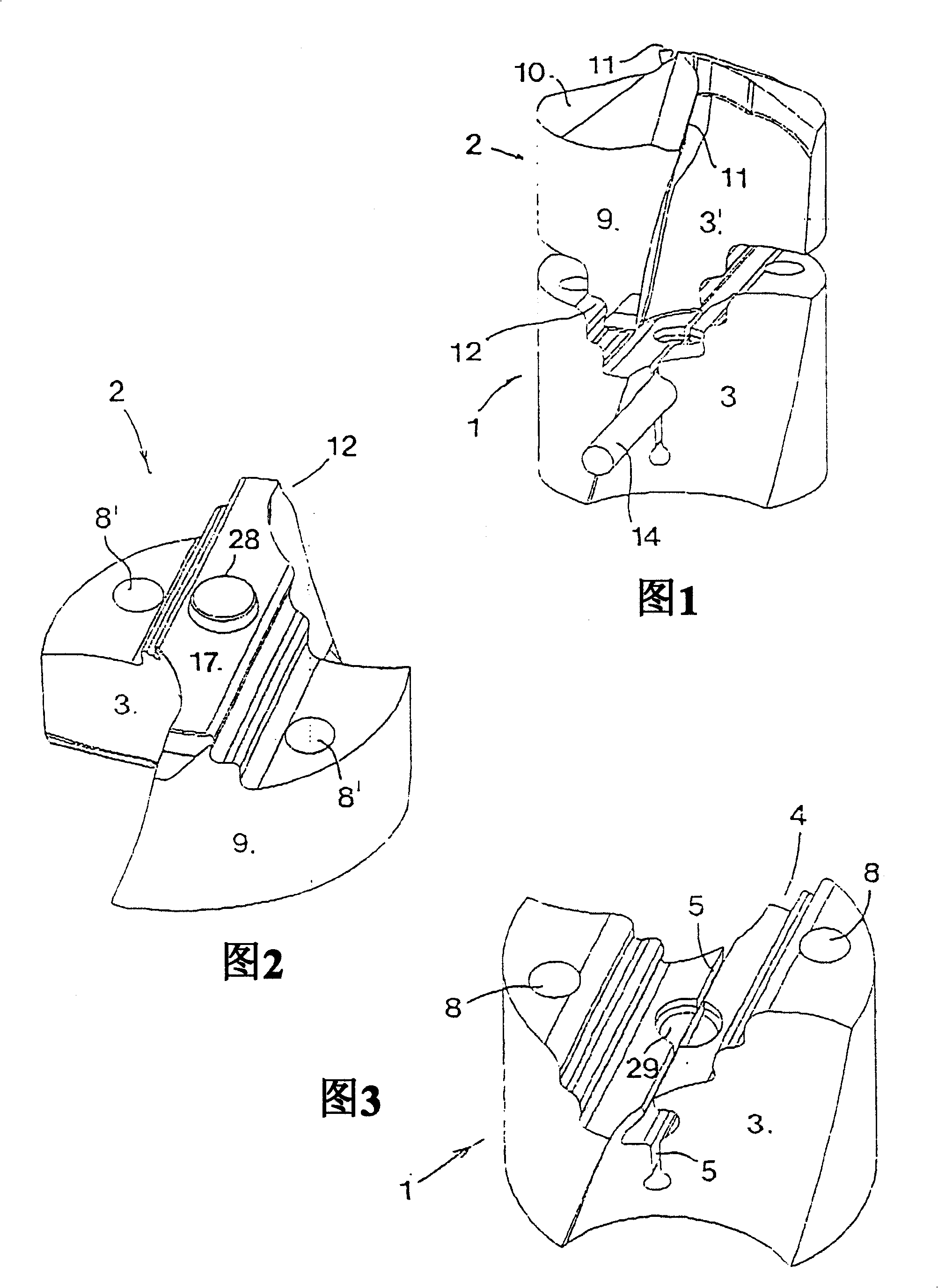

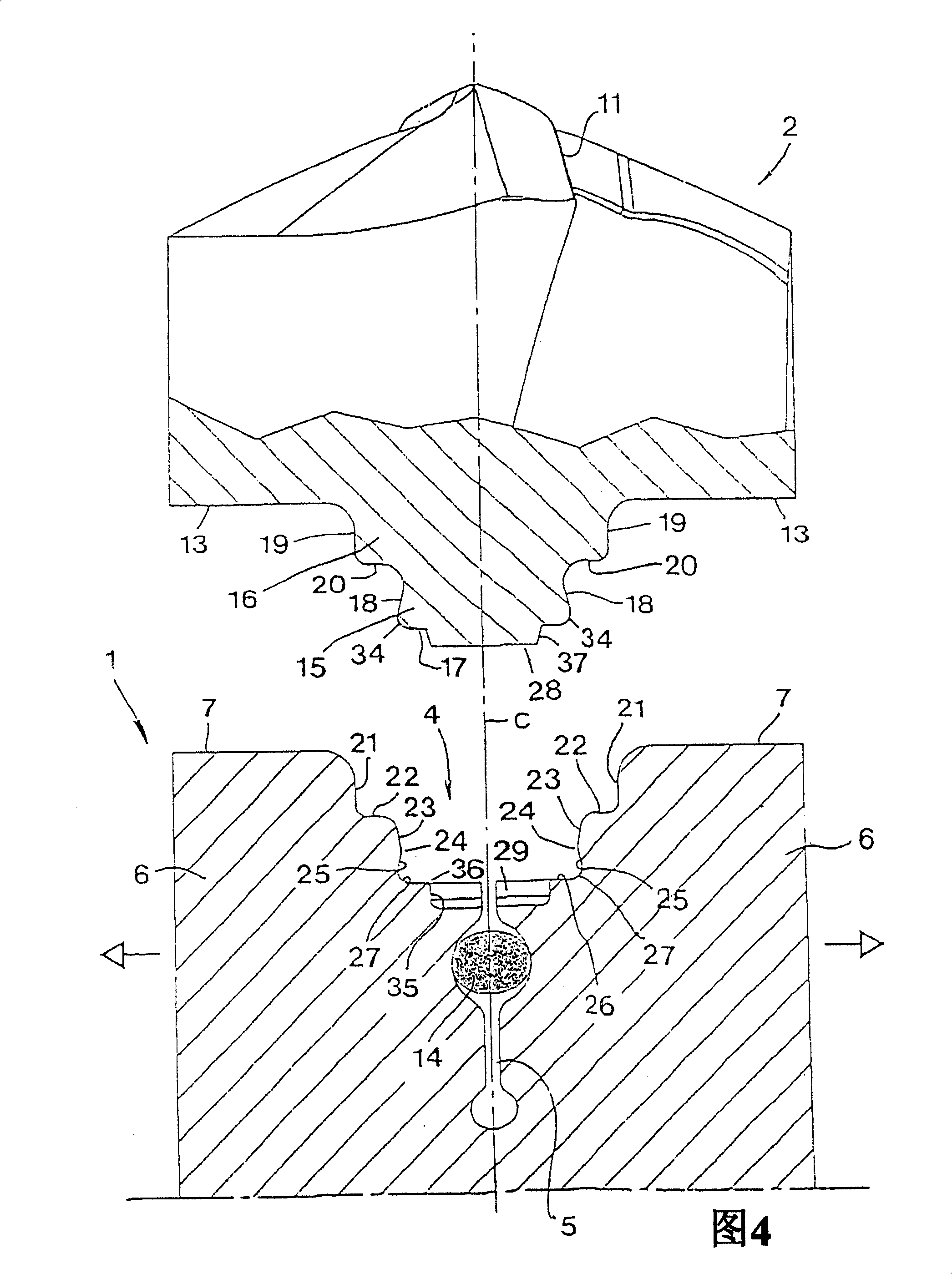

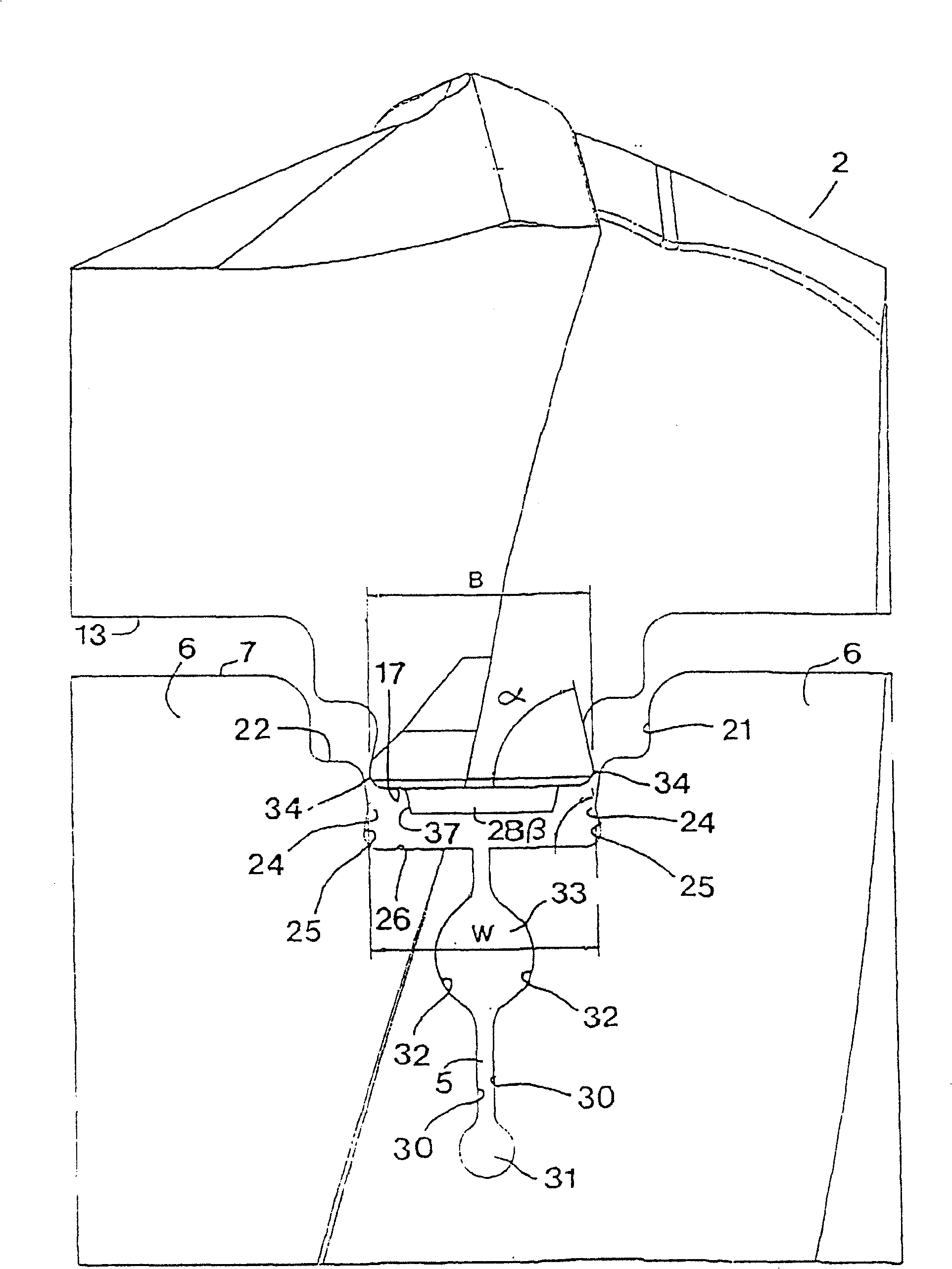

[0016] The tool shown in FIGS. 1-8 is in the form of a drill bit which generally comprises a base body generally indicated at 1 and a replaceable cutting portion or removable top 2 . The basic body 1 is formed in this case by an elongated shank with a cylindrical basic shape, which is shown in the disconnected state in these figures. The base body can be mounted in a suitable manner in a machine tool, for example a multi-operation machine tool, and has two helical, concavely curved interfaces 3 in cross-section, these delimiting surfaces forming the chip flutes. In the front or outer end of the base body 1 is formed a groove 4 in which a slit 5 is cut, which separates two elastically deflectable legs 6 . On both sides of the groove 4 there are thrust transmission surfaces 7 in which grooves 8 are cut for feeding cooling liquid to corresponding grooves 8' in the removable top 2 .

[0017] The removable top 2 has a rotationally symmetrical basic shape, here it has a circular ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com