Pure hardware separation system of non sensor brushless DC motor zero start

A brushed DC motor and discrete system technology, applied in control systems, electrical components, electronic commutation motor control, etc., can solve problems such as poor zero-start performance, heavy computing load, and difficult cost control, and achieve high stability and reliability , fast processing speed, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

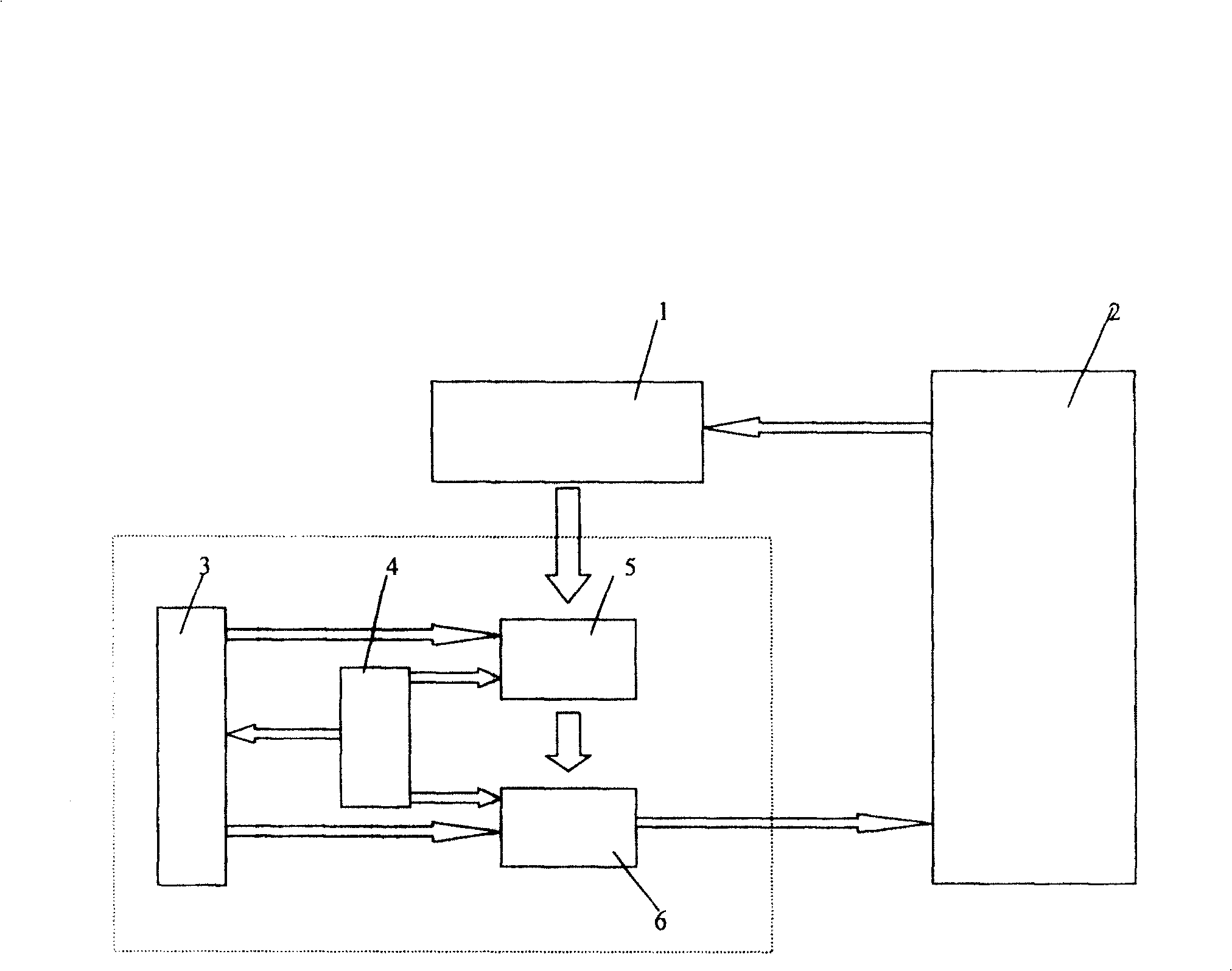

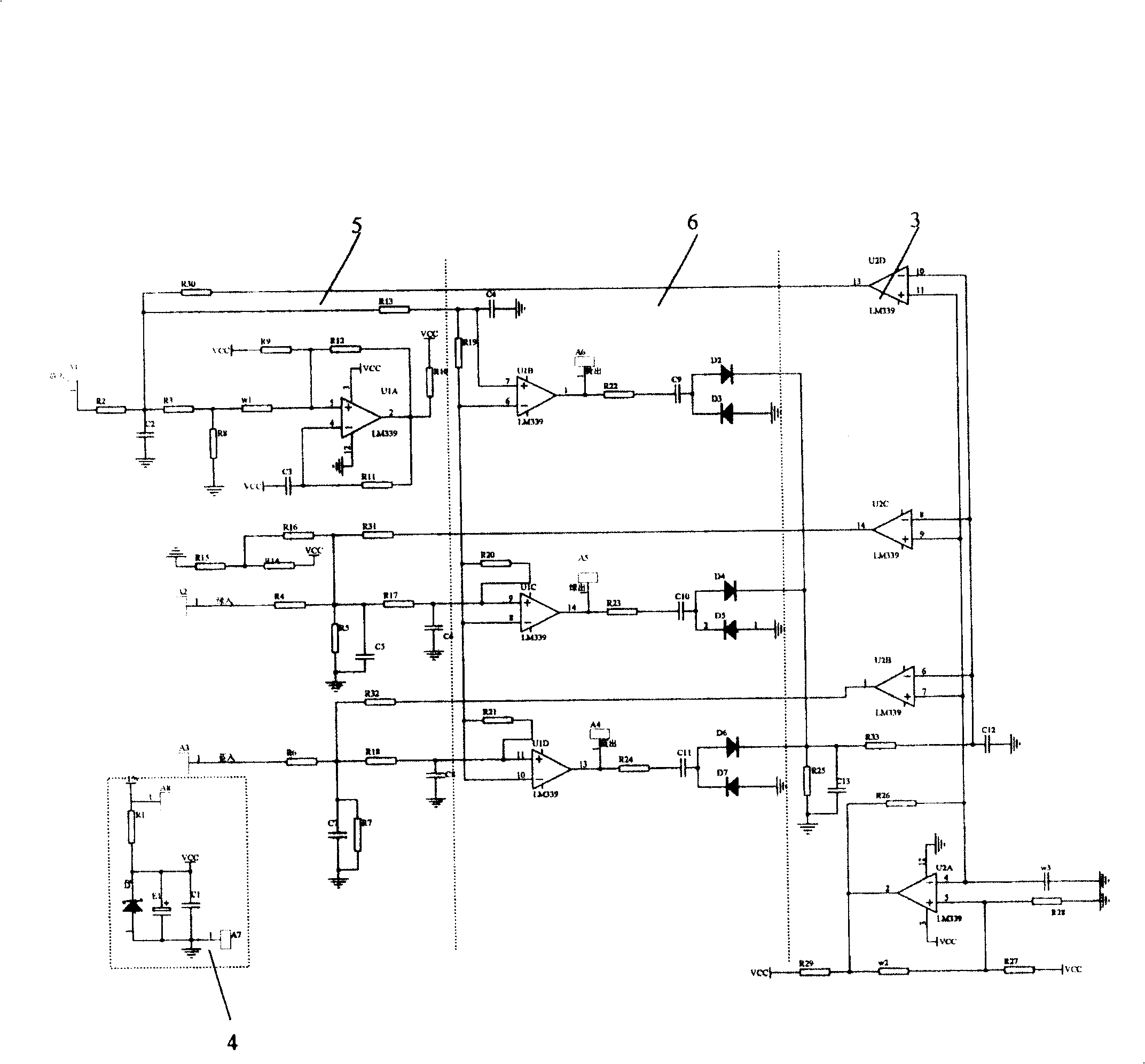

[0022] like figure 1 As shown, a sensorless brushless DC motor zero-start pure hardware discrete system of the present invention includes a brushless DC motor 1, a brushless DC motor controller 2, a feedback compensation circuit 3, a stabilized power supply circuit 4, and a filter delay Circuit 5 and zero-crossing detection circuit 6; brushless DC motor 1 is connected to filter delay circuit 5; stabilized power supply circuit 4 is respectively connected to feedback compensation circuit 3, filter delay circuit 5 and zero-crossing detection circuit 6; feedback compensation circuit 3 is respectively It is connected with the filter delay circuit 5 and the zero-crossing detection circuit 6; the filter delay circuit 5 is connected with the brushless DC motor controller 2 through the zero detection circuit 6; the brushless DC motor controller 2 is connected with the brushless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com