Orbiting vane compressor

一种旋转叶片、压缩机的技术,应用在旋转活塞式机械、旋转活塞式泵、旋转活塞式/摆动活塞式的泵部件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

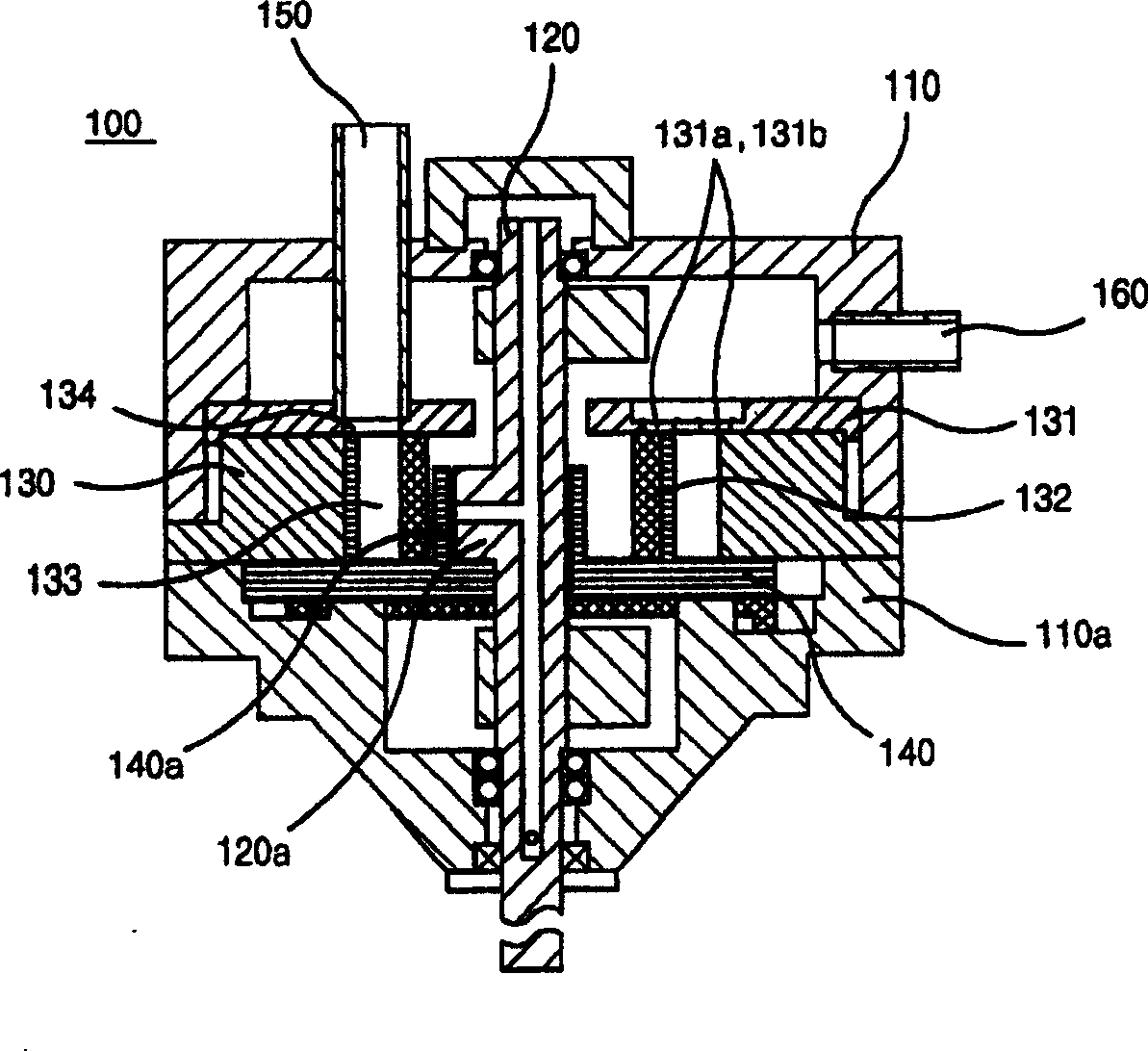

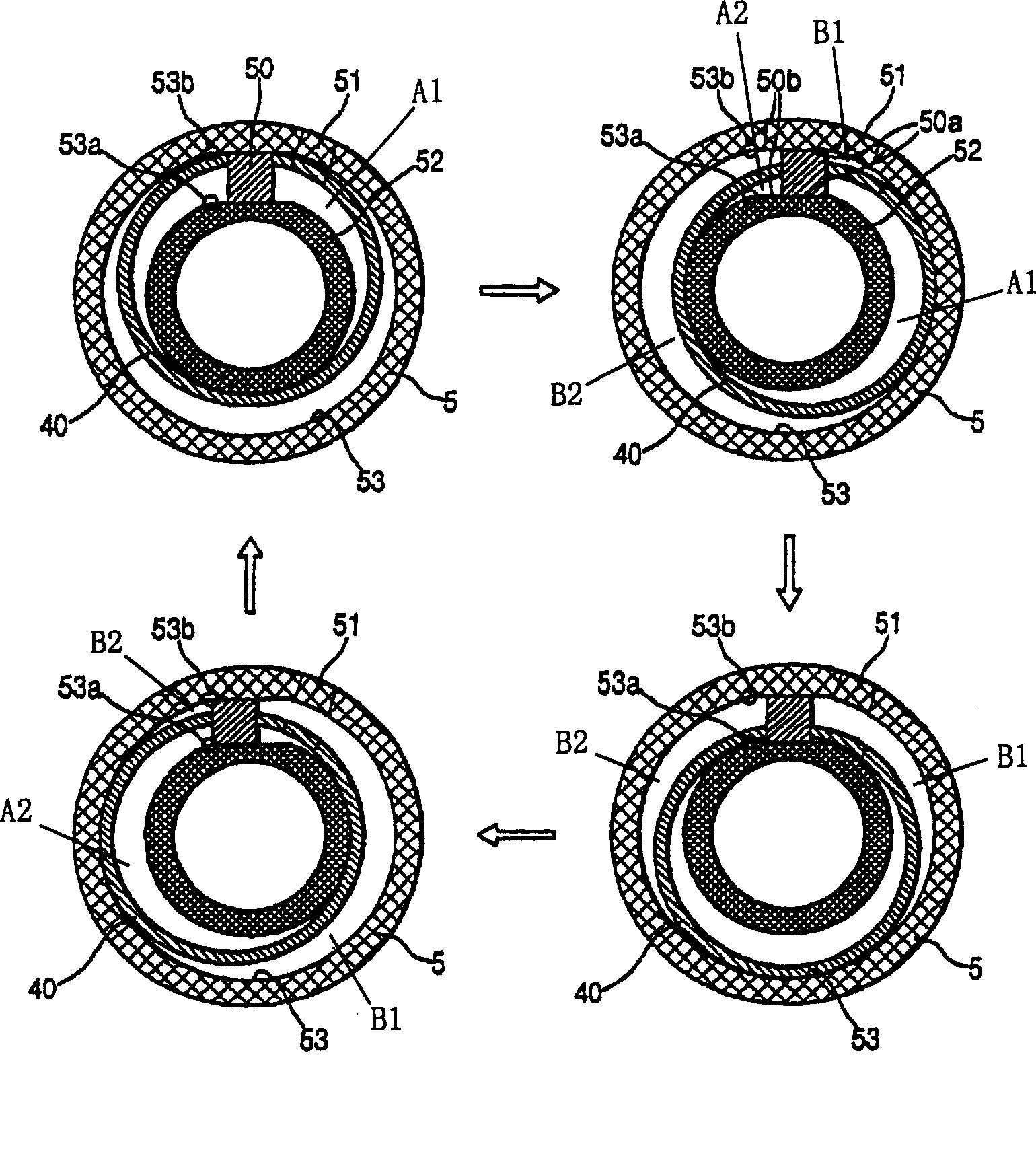

Image

Examples

Embodiment Construction

[0039] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

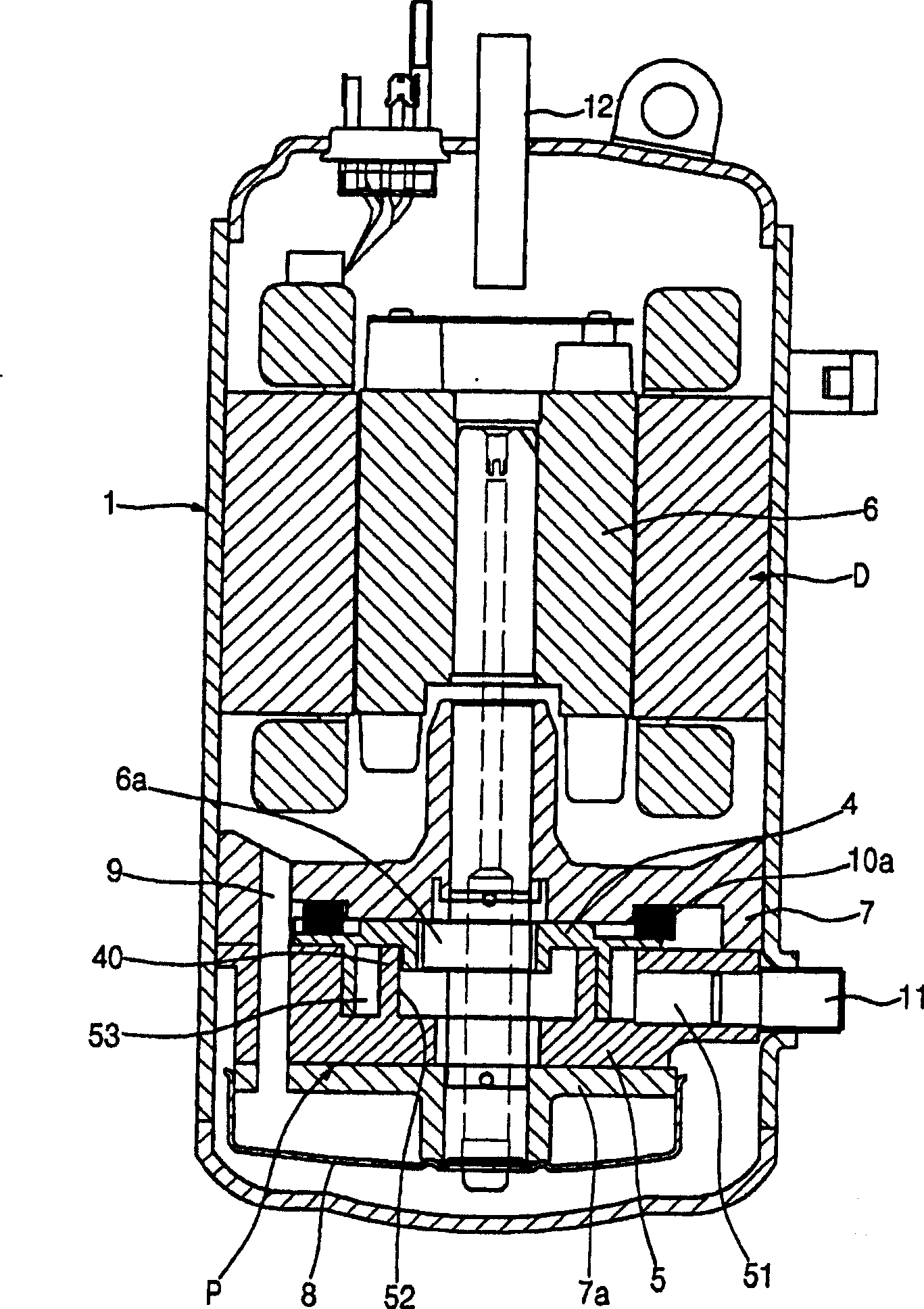

[0040] figure 2 is a longitudinal sectional view illustrating the overall structure of the hermetically sealed rotary vane compressor according to the first preferred embodiment of the present invention.

[0041] Such as figure 2 As shown, the driving part D and the compressing part P are mounted in the housing 1 while the driving part D and the compressing part P are sealed. The driving part D is disposed above the inside of the housing 1 , and the compression part P is disposed below the inside of the housing 1 . The drive part D and the compression part P are connected to each other by a vertical shaft 6 . The rotary shaft 6 has an eccentric portion 6a.

[0042] The driving part D includes: a stator 2 fixedly provided in a housing 1 ; and a rotor 3 provided in the stator 2 , which rotates a rotating shaft 6 vertically extending through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com