Gas Turbine Compressor Cascade Shroud with Spatial Structure

A gas turbine and space structure technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of gas turbine power increase, large resistance, uneven air flow of the compressor, etc., and achieve compressor performance Improvement, compression performance improvement, and the effect of increasing structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be further described in conjunction with accompanying drawing:

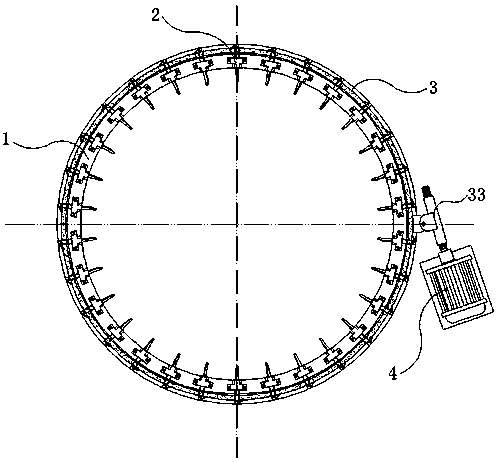

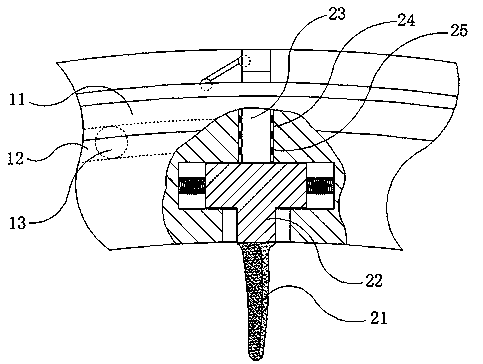

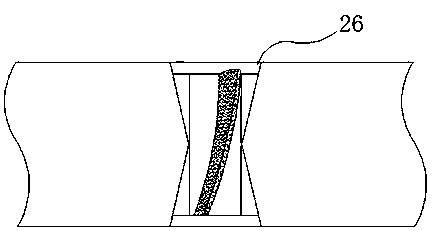

[0019] combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a gas turbine compressor blade cascade shroud with a space structure disclosed in the present invention includes a belt ring 1, an equal section 2, a moving ring 3 and a driving device 4, and the belt ring 1 is evenly arranged and installed with a plurality of The equal section 2 and the moving ring 3 are set on the mouth platform with the ring 1, and the moving ring 3 drives all the equal sections 2 to rotate synchronously, and the driving device 4 provides specific rotation precision values for the moving ring. The belt ring 1 is in the form of a platform, which is used to connect the overall structural support and the outside. The outer end of the belt ring 1 can be provided with a retaining ring 11, and the belt ring 1 can be provided with a rolling groove 12, and the rolling groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com